How Graphite Electrodes Are Revolutionizing Energy Production

Summary:

How Graphite Electrodes Are Revolutionizing Energy Production

Table of Contents

1. Introduction to Graphite Electrodes

2. Understanding Graphite: A Non-Metallic Marvel

3. The Role of Graphite Electrodes in Energy Production

4. Key Applications of Graphite Electrodes in Energy Sector

5. Advantages of Graphite Electrodes Over Traditional Materials

6. Challenges in Utilizing Graphite Ele

How Graphite Electrodes Are Revolutionizing Energy Production

Table of Contents

- 1. Introduction to Graphite Electrodes

- 2. Understanding Graphite: A Non-Metallic Marvel

- 3. The Role of Graphite Electrodes in Energy Production

- 4. Key Applications of Graphite Electrodes in Energy Sector

- 5. Advantages of Graphite Electrodes Over Traditional Materials

- 6. Challenges in Utilizing Graphite Electrodes

- 7. The Future of Graphite Electrodes in Energy Production

- 8. Conclusion

- 9. Frequently Asked Questions

1. Introduction to Graphite Electrodes

Graphite electrodes play a critical role in modern energy production. As industries seek sustainable and efficient solutions, these electrodes are becoming increasingly popular for their unique properties and performance characteristics. By understanding their composition, applications, and benefits, we can appreciate how they are changing the energy landscape.

2. Understanding Graphite: A Non-Metallic Marvel

Graphite is a form of carbon characterized by its layered structure, which enables excellent thermal and electrical conductivity. Unlike metallic electrodes, graphite electrodes are non-metallic, which reduces the risk of corrosion and improves their longevity. This unique structure makes graphite an ideal material for high-temperature applications, particularly in electric arc furnaces and other energy production processes.

2.1 The Composition of Graphite Electrodes

Graphite electrodes are primarily composed of petroleum coke and coal tar pitch. These raw materials are subjected to high-temperature treatment to create a material that can withstand extreme conditions. The resulting product is not only cost-effective but also efficient in energy transfer, making it a preferred choice in various industrial applications.

2.2 The Importance of Purity in Graphite Electrodes

The purity of graphite electrodes is crucial. High-quality electrodes with minimal impurities enhance electrical conductivity and thermal efficiency. This leads to improved performance in energy production while reducing operational costs and environmental impact.

3. The Role of Graphite Electrodes in Energy Production

Graphite electrodes are essential in the production of electric arc furnaces (EAFs), which are pivotal in recycling scrap steel and producing new steel. Additionally, they are used in various energy-related applications, such as in batteries and fuel cells, showcasing their versatility and adaptability in the evolving energy landscape.

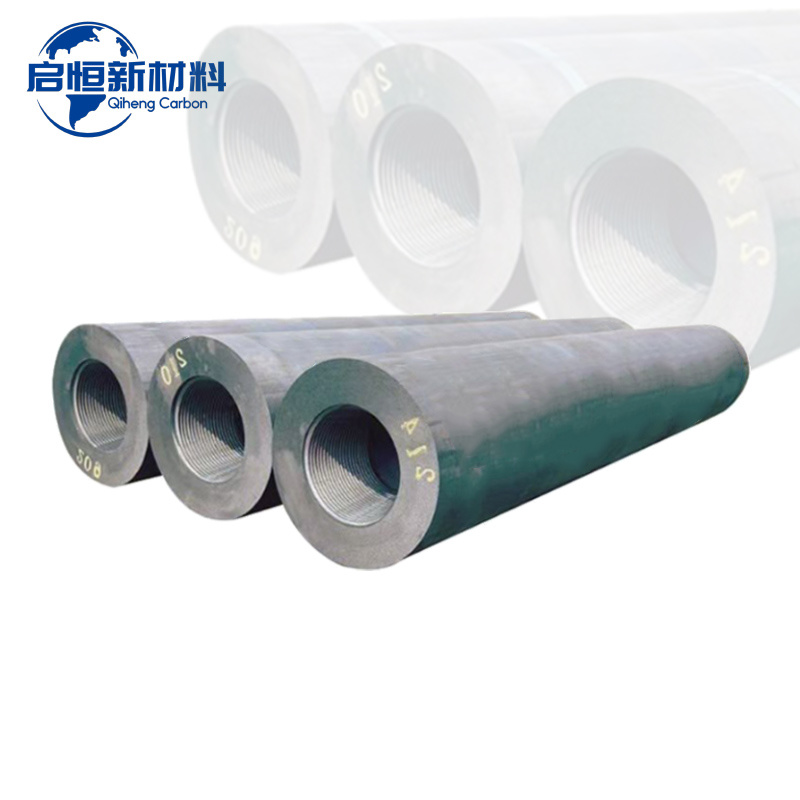

3.1 Graphite Electrodes in Electric Arc Furnaces

EAFs utilize graphite electrodes to generate the high temperatures necessary for melting scrap steel. These electrodes allow for precise temperature control and efficient energy usage, making them an environmentally friendly alternative to traditional blast furnaces.

3.2 Applications in Renewable Energy

The integration of graphite electrodes into renewable energy technologies is gaining momentum. For instance, they are used in lithium-ion batteries, which power electric vehicles and renewable energy storage systems. Their ability to facilitate efficient energy transfer makes them indispensable in the transition to a more sustainable energy future.

4. Key Applications of Graphite Electrodes in Energy Sector

Graphite electrodes find numerous applications across various segments of energy production. Understanding these applications helps in recognizing their significance in driving efficiency and sustainability.

4.1 Steel Production

In steel production, graphite electrodes are used in EAFs to melt scrap metal. The process is not only energy-efficient but also reduces carbon emissions, making it a greener alternative.

4.2 Battery Manufacturing

Graphite electrodes are critical components in lithium-ion batteries, which power everything from smartphones to electric vehicles. Their unique properties allow for better charge retention and faster charging times, enhancing overall battery performance.

4.3 Fuel Cells

Fuel cells utilize graphite electrodes to facilitate electrochemical reactions, making them essential in hydrogen fuel technology. This application contributes significantly to clean energy initiatives and reduces the dependency on fossil fuels.

5. Advantages of Graphite Electrodes Over Traditional Materials

Graphite electrodes offer several advantages over traditional metallic electrodes, significantly impacting efficiency and sustainability in energy production.

5.1 High Thermal and Electrical Conductivity

One of the most notable benefits of graphite electrodes is their high thermal and electrical conductivity. This property allows for efficient energy transfer, which is essential in high-temperature applications like EAFs.

5.2 Corrosion Resistance

Graphite electrodes are less prone to corrosion compared to their metallic counterparts. This property enhances their durability and reduces maintenance costs, making them a cost-effective choice in the long run.

5.3 Sustainable Production Process

The production of graphite electrodes can be more sustainable compared to traditional materials. The process often utilizes recycled materials, contributing to a circular economy and reducing waste.

6. Challenges in Utilizing Graphite Electrodes

Despite their advantages, the use of graphite electrodes is not without challenges. Acknowledging these hurdles is important for future development and optimization.

6.1 Supply Chain Issues

The supply chain for graphite and its raw materials can be complex and subject to fluctuations. This can impact the availability and cost of high-quality graphite electrodes.

6.2 Environmental Concerns

While graphite electrodes are more sustainable than many alternatives, their production still has an environmental footprint. Addressing these concerns is crucial for their acceptance and widespread use in energy production.

6.3 Technological Advancements

As technology evolves, the demand for more efficient and innovative materials grows. Continuous research and development are necessary to enhance the performance of graphite electrodes and maintain their competitive edge.

7. The Future of Graphite Electrodes in Energy Production

The future of graphite electrodes in energy production looks promising. As industries strive for greater efficiency and sustainability, the demand for these electrodes is expected to increase.

7.1 Innovations in Graphite Manufacturing

Advancements in manufacturing techniques are likely to improve the quality and performance of graphite electrodes. Innovations such as enhanced purification processes and the use of alternative raw materials could reshape the industry.

7.2 Increased Adoption in Renewable Technologies

As the world shifts towards renewable energy sources, the role of graphite electrodes in technologies such as solar cells and energy storage systems will expand. Their properties make them ideal for integrating with various renewable energy solutions.

7.3 Regulatory Support and Environmental Standards

Government initiatives and regulations promoting sustainability will likely accelerate the adoption of graphite electrodes. As industries seek compliance with environmental standards, the shift towards these non-metallic materials will become more pronounced.

8. Conclusion

In summary, graphite electrodes are reshaping the energy production landscape by offering efficient, sustainable alternatives to traditional materials. Their unique properties and applications across various sectors make them essential for the future of energy. As we continue to innovate and overcome challenges, graphite electrodes will undoubtedly play a pivotal role in driving the energy sector towards a more sustainable future.

9. Frequently Asked Questions

Q1: What are graphite electrodes used for?

A1: Graphite electrodes are primarily used in electric arc furnaces for steel production, as well as in batteries and fuel cells for various energy applications.

Q2: Why are graphite electrodes preferred over metal electrodes?

A2: Graphite electrodes offer superior thermal and electrical conductivity, corrosion resistance, and a more sustainable production process, making them preferable for many applications.

Q3: What challenges do graphite electrodes face in the industry?

A3: Challenges include supply chain issues, environmental concerns regarding production, and the need for continuous technological advancements.

Q4: How do graphite electrodes contribute to renewable energy?

A4: Graphite electrodes are used in renewable technologies like lithium-ion batteries and fuel cells, facilitating clean energy solutions and reducing reliance on fossil fuels.

Q5: What is the future outlook for graphite electrodes in energy production?

A5: The future is promising, with expected innovations in manufacturing, increased adoption in renewable technologies, and supportive regulatory frameworks driving their growth in the energy sector.

Focus On Hot Spots

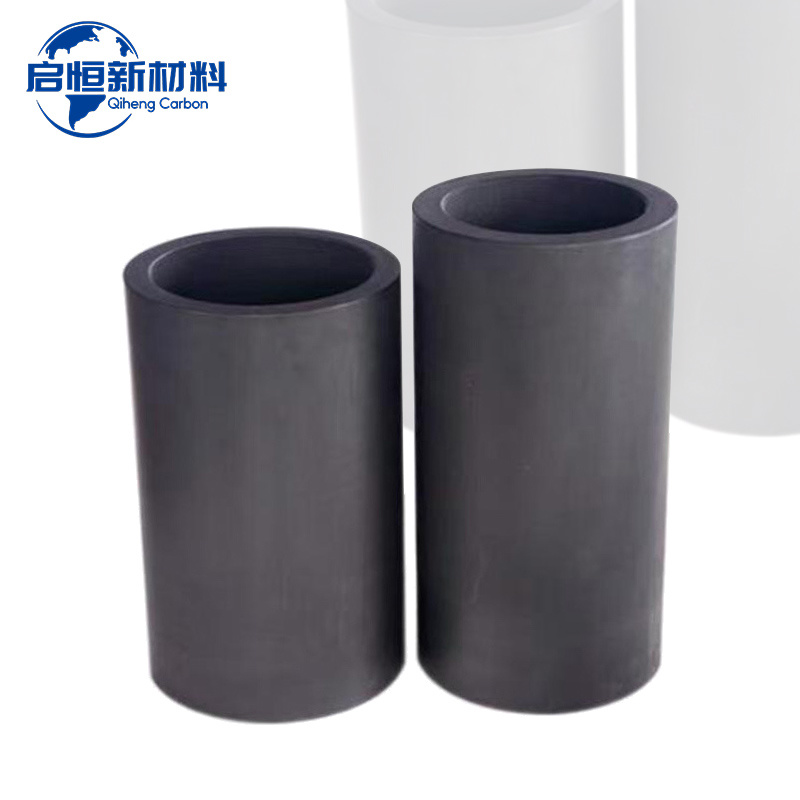

Understanding the Lifecycle of a Graphite Crucible: From Creation to Application

Understanding the Lifecycle of a Graphite Crucible

Graphite crucibles are essential tools widely used in various industrial applications, particularly in metallurgy. Their unique properties, such as high thermal conductivity and resistance to thermal shock, make them indispensable for melting metals and other applications. In this article, we will delve into the lifecycle of a graphite crucible, e

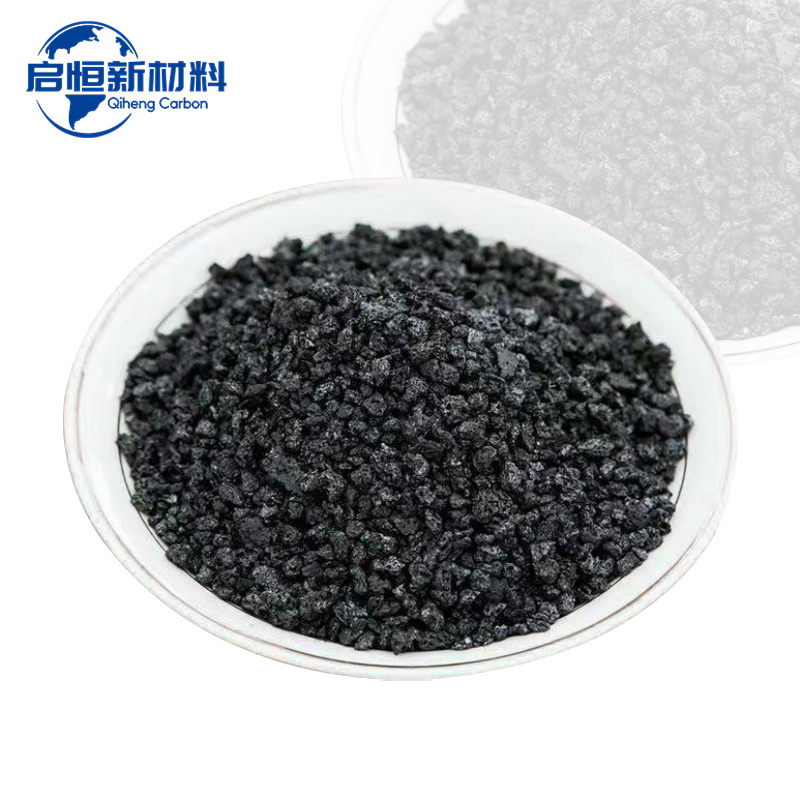

Understanding Calcined Petroleum Coke: Properties, Applications, and Benefits

Calcined petroleum coke (CPC) is a carbonaceous solid material derived from the thermal processing of green petroleum coke, which is produced during the oil refining process. The calcination process involves heating green petroleum coke to high temperatures (approximately 1200°C to 1400°C) in a controlled atmosphere, which drives off volatile compounds and enhances the carbon content, resulting in