Understanding the Lifecycle of a Graphite Crucible: From Creation to Application

Summary:

Understanding the Lifecycle of a Graphite Crucible

Graphite crucibles are essential tools widely used in various industrial applications, particularly in metallurgy. Their unique properties, such as high thermal conductivity and resistance to thermal shock, make them indispensable for melting metals and other applications. In this article, we will delve into the lifecycle of a graphite crucible, e

Understanding the Lifecycle of a Graphite Crucible

Graphite crucibles are essential tools widely used in various industrial applications, particularly in metallurgy. Their unique properties, such as high thermal conductivity and resistance to thermal shock, make them indispensable for melting metals and other applications. In this article, we will delve into the lifecycle of a graphite crucible, examining the stages from manufacturing to disposal and recycling.

Table of Contents

1. Introduction to Graphite Crucibles

2. Properties of Graphite Crucibles

3. The Manufacturing Process of Graphite Crucibles

3.1 Raw Material Selection

3.2 Shaping and Forming Techniques

3.3 Curing and Firing Processes

4. Applications of Graphite Crucibles

4.1 Use in Metallurgy

4.2 Role in Foundries

4.3 Applications in the Glass and Ceramics Industries

5. The Lifespan of Graphite Crucibles

5.1 Factors Affecting Longevity

5.2 Wear and Tear in Use

6. Recycling and Sustainable Disposal of Graphite Crucibles

6.1 Methods of Recycling

6.2 Importance of Sustainable Practices

7. FAQs About Graphite Crucibles

8. Conclusion

1. Introduction to Graphite Crucibles

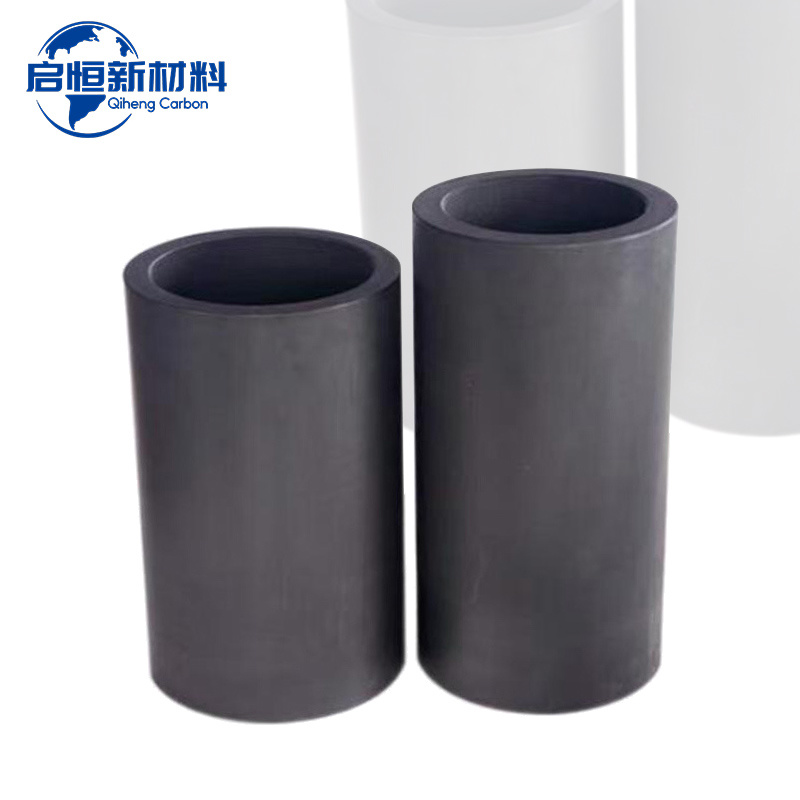

Graphite crucibles have become a cornerstone in industrial processes, particularly for melting and casting metals. These products are made from high-purity graphite, which offers excellent thermal stability and chemical resistance. Understanding the lifecycle of a graphite crucible not only highlights its significance in various manufacturing processes but also sheds light on its environmental impact and sustainability.

2. Properties of Graphite Crucibles

The remarkable properties of graphite crucibles are what set them apart from other melting containers. Some of the notable characteristics include:

- **High Thermal Conductivity**: Graphite crucibles can withstand extreme temperatures, making them ideal for melting metals like gold, silver, and aluminum.

- **Chemical Inertness**: They resist chemical reactions with molten metals, ensuring purity in the final product.

- **Excellent Thermal Shock Resistance**: Graphite can endure rapid temperature changes without cracking, which is crucial during the melting process.

These properties contribute to the efficiency and effectiveness of graphite crucibles in various industrial applications.

3. The Manufacturing Process of Graphite Crucibles

The production of graphite crucibles involves several intricate steps, ensuring that the final product meets the high standards required by industries.

3.1 Raw Material Selection

The foundation of a quality graphite crucible lies in selecting the right raw materials. High-purity natural or synthetic graphite is typically used, which ensures superior performance during high-temperature applications. The selection process also considers the specific requirements of the intended application.

3.2 Shaping and Forming Techniques

Once the raw materials are selected, the next step is shaping and forming. There are various techniques used in this step, including:

- **Extrusion**: This method involves forcing the graphite mixture through a die to create crucibles of specific shapes and sizes.

- **Casting**: Liquid graphite is poured into molds to form crucibles, allowing for more complex shapes.

These techniques are vital in ensuring that the crucibles are manufactured in various sizes and designs suitable for different applications.

3.3 Curing and Firing Processes

After shaping, the crucibles undergo a curing process to solidify their structure. This process involves heating the crucibles at controlled temperatures, allowing chemical bonds to form within the graphite material. Subsequently, firing the crucibles at high temperatures further enhances their mechanical strength and thermal shock resistance, making them ready for industrial use.

4. Applications of Graphite Crucibles

Graphite crucibles are versatile tools used across various industries. Their unique properties allow them to play crucial roles in multiple applications.

4.1 Use in Metallurgy

In metallurgy, graphite crucibles are primarily used for melting and refining metals. Their ability to withstand high temperatures without deforming makes them ideal for this purpose. Common metals melted in graphite crucibles include:

- **Gold**

- **Silver**

- **Copper**

- **Aluminum**

The purity of the materials is maintained due to the crucible's chemical inertness, ensuring high-quality metal recovery.

4.2 Role in Foundries

Foundries rely heavily on graphite crucibles for casting processes. They provide a reliable means of melting metals before pouring them into molds. The efficiency of the melting process directly affects production timelines, making the use of high-quality graphite crucibles essential.

4.3 Applications in the Glass and Ceramics Industries

Aside from metallurgy, graphite crucibles are also employed in the glass and ceramics industries. They are used for melting glass and other materials due to their resistance to thermal shock and chemical interactions. This application showcases the versatility of graphite crucibles across diverse sectors.

5. The Lifespan of Graphite Crucibles

Understanding the lifespan of a graphite crucible is crucial for industrial applications, as it directly impacts productivity and cost.

5.1 Factors Affecting Longevity

Several factors influence the lifespan of a graphite crucible, including:

- **Quality of Raw Materials**: The purity and quality of the graphite used can significantly affect the crucible's durability.

- **Operating Temperature**: Prolonged exposure to extreme temperatures can shorten the crucible's lifespan.

- **Usage Frequency**: Regular heavy use can lead to wear and tear over time.

These factors must be considered when selecting and using graphite crucibles in industrial settings.

5.2 Wear and Tear in Use

Graphite crucibles inevitably undergo wear and tear during their use. Common signs of degradation include cracks, chips, and loss of shape. Regular inspections can help identify issues early, allowing for timely replacements and minimizing downtime.

6. Recycling and Sustainable Disposal of Graphite Crucibles

Recycling graphite crucibles is an essential aspect of their lifecycle, contributing to environmental sustainability.

6.1 Methods of Recycling

Graphite crucibles can be recycled through various methods, including:

- **Reprocessing**: The used crucibles can be ground into a fine powder and reprocessed to create new products.

- **Melting Down**: In some cases, graphite can be melted and remolded into new crucibles.

These methods help reduce waste and promote a circular economy in the graphite crucible industry.

6.2 Importance of Sustainable Practices

As industries become more environmentally conscious, adopting sustainable practices surrounding the lifecycle management of graphite crucibles is becoming increasingly essential. By recycling and properly disposing of these products, companies can minimize their environmental footprint and contribute to a more sustainable future.

7. FAQs About Graphite Crucibles

1. What is a graphite crucible?

A graphite crucible is a container made primarily from high-purity graphite, used for melting and casting metals and other materials.

2. Why are graphite crucibles preferred for melting metals?

Graphite crucibles offer high thermal conductivity, chemical inertness, and excellent thermal shock resistance, making them ideal for high-temperature applications.

3. How long do graphite crucibles last?

The lifespan of a graphite crucible can vary based on factors such as operating temperature, quality of materials, and usage frequency. Regular inspections and maintenance can help extend their life.

4. Can graphite crucibles be recycled?

Yes, graphite crucibles can be recycled through methods such as reprocessing and melting down, contributing to sustainability in the industry.

5. What industries utilize graphite crucibles?

Graphite crucibles are commonly used in metallurgy, foundries, and the glass and ceramics industries.

8. Conclusion

Understanding the lifecycle of a graphite crucible reveals its vital role in various industrial applications. From its manufacturing process to its applications and sustainable disposal methods, the complexities of graphite crucibles highlight their importance in metallurgy and beyond. By prioritizing quality and sustainability, industries can maximize the benefits of graphite crucibles while minimizing their environmental impact. As technology evolves, the future of graphite crucibles looks promising, paving the way for continued innovation and sustainability in the field.

Previous:

Focus On Hot Spots

Understanding the Lifecycle of a Graphite Crucible: From Creation to Application

Understanding the Lifecycle of a Graphite Crucible

Graphite crucibles are essential tools widely used in various industrial applications, particularly in metallurgy. Their unique properties, such as high thermal conductivity and resistance to thermal shock, make them indispensable for melting metals and other applications. In this article, we will delve into the lifecycle of a graphite crucible, e

Understanding Calcined Petroleum Coke: Properties, Applications, and Benefits

Calcined petroleum coke (CPC) is a carbonaceous solid material derived from the thermal processing of green petroleum coke, which is produced during the oil refining process. The calcination process involves heating green petroleum coke to high temperatures (approximately 1200°C to 1400°C) in a controlled atmosphere, which drives off volatile compounds and enhances the carbon content, resulting in