Understanding Calcined Petroleum Coke: Properties, Applications, and Benefits

Summary:

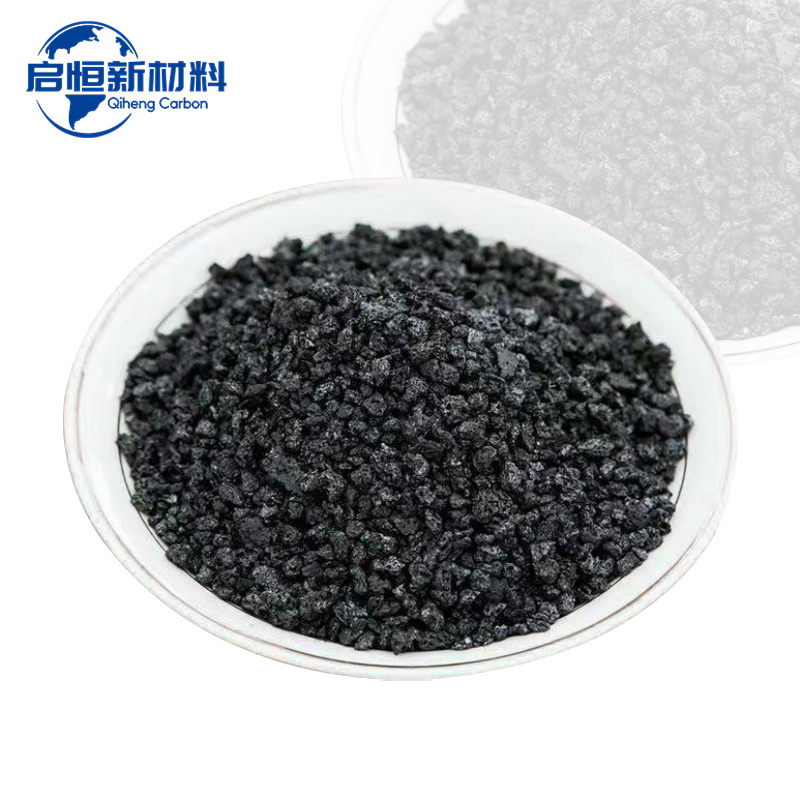

Calcined petroleum coke (CPC) is a carbonaceous solid material derived from the thermal processing of green petroleum coke, which is produced during the oil refining process. The calcination process involves heating green petroleum coke to high temperatures (approximately 1200°C to 1400°C) in a controlled atmosphere, which drives off volatile compounds and enhances the carbon content, resulting in

Calcined petroleum coke (CPC) is a carbonaceous solid material derived from the thermal processing of green petroleum coke, which is produced during the oil refining process. The calcination process involves heating green petroleum coke to high temperatures (approximately 1200°C to 1400°C) in a controlled atmosphere, which drives off volatile compounds and enhances the carbon content, resulting in a highly pure and conductive material.

One of the primary properties of calcined petroleum coke is its high carbon content, typically exceeding 98%. This purity makes CPC an ideal material for producing electrodes used in steelmaking and aluminum smelting. The low levels of impurities, such as sulfur and ash, further enhance its suitability for applications requiring high thermal and electrical conductivity.

In addition to its role in the production of electrodes, calcined petroleum coke is also utilized as a filler material in the manufacturing of various products, including batteries, lubricants, and carbon anodes. The material's ability to withstand high temperatures and its chemical stability make it a valuable component in the production of advanced materials and composites.

Moreover, CPC is known for its excellent resistance to oxidation and thermal shock, making it a preferred choice in high-temperature applications. Its unique properties enable it to be used in the production of high-performance industrial products, which require durability and efficiency under extreme conditions.

Calcined petroleum coke also plays a crucial role in the production of graphite products. The high purity and structural integrity of CPC make it suitable for the creation of high-quality graphite electrodes, which are essential for electric arc furnaces used in steel production. The demand for calcined petroleum coke in the graphite manufacturing sector has been steadily increasing, driven by the growing need for advanced materials in various industries.

In summary, calcined petroleum coke is a vital material with diverse applications across multiple sectors, including metallurgy, battery production, and advanced materials development. Its high carbon content, low impurities, and excellent thermal and electrical properties make it a preferred choice for several industrial processes. As industries continue to evolve and demand enhanced materials, the importance of calcined petroleum coke is set to grow, highlighting its significance in the chemical and petroleum fields. Understanding its properties and applications can provide valuable insights for professionals seeking to leverage this essential material in their operations.

One of the primary properties of calcined petroleum coke is its high carbon content, typically exceeding 98%. This purity makes CPC an ideal material for producing electrodes used in steelmaking and aluminum smelting. The low levels of impurities, such as sulfur and ash, further enhance its suitability for applications requiring high thermal and electrical conductivity.

In addition to its role in the production of electrodes, calcined petroleum coke is also utilized as a filler material in the manufacturing of various products, including batteries, lubricants, and carbon anodes. The material's ability to withstand high temperatures and its chemical stability make it a valuable component in the production of advanced materials and composites.

Moreover, CPC is known for its excellent resistance to oxidation and thermal shock, making it a preferred choice in high-temperature applications. Its unique properties enable it to be used in the production of high-performance industrial products, which require durability and efficiency under extreme conditions.

Calcined petroleum coke also plays a crucial role in the production of graphite products. The high purity and structural integrity of CPC make it suitable for the creation of high-quality graphite electrodes, which are essential for electric arc furnaces used in steel production. The demand for calcined petroleum coke in the graphite manufacturing sector has been steadily increasing, driven by the growing need for advanced materials in various industries.

In summary, calcined petroleum coke is a vital material with diverse applications across multiple sectors, including metallurgy, battery production, and advanced materials development. Its high carbon content, low impurities, and excellent thermal and electrical properties make it a preferred choice for several industrial processes. As industries continue to evolve and demand enhanced materials, the importance of calcined petroleum coke is set to grow, highlighting its significance in the chemical and petroleum fields. Understanding its properties and applications can provide valuable insights for professionals seeking to leverage this essential material in their operations.

Focus On Hot Spots

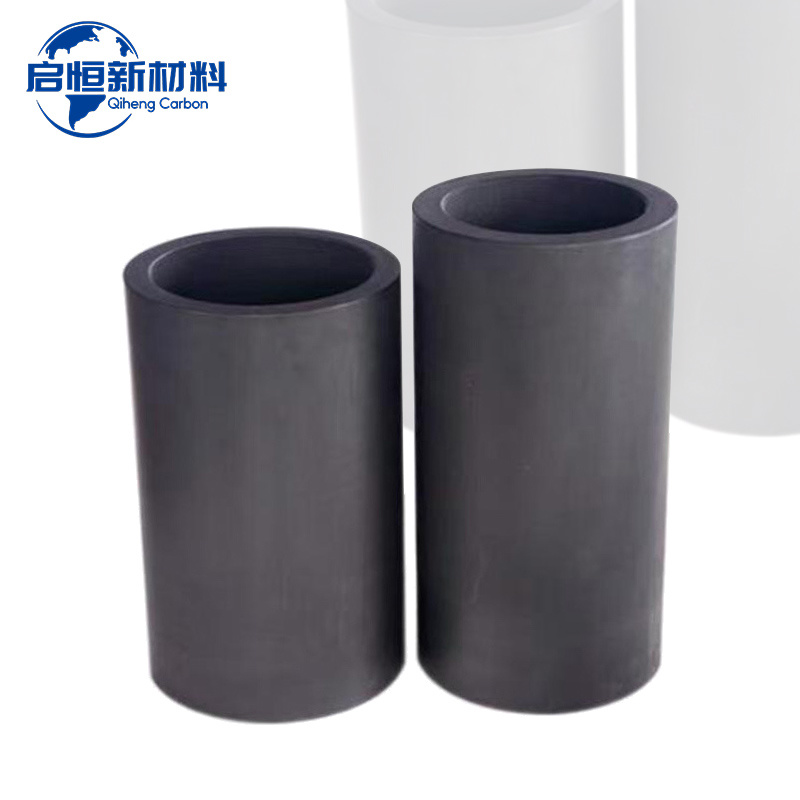

Understanding the Lifecycle of a Graphite Crucible: From Creation to Application

Understanding the Lifecycle of a Graphite Crucible

Graphite crucibles are essential tools widely used in various industrial applications, particularly in metallurgy. Their unique properties, such as high thermal conductivity and resistance to thermal shock, make them indispensable for melting metals and other applications. In this article, we will delve into the lifecycle of a graphite crucible, e

Understanding Calcined Petroleum Coke: Properties, Applications, and Benefits

Calcined petroleum coke (CPC) is a carbonaceous solid material derived from the thermal processing of green petroleum coke, which is produced during the oil refining process. The calcination process involves heating green petroleum coke to high temperatures (approximately 1200°C to 1400°C) in a controlled atmosphere, which drives off volatile compounds and enhances the carbon content, resulting in