Innovations in Graphite Electrode Connector Technology: A Deep Dive into the Future

Summary:

Innovations in Graphite Electrode Connector Technology: What You Need to Know

In the rapidly evolving field of electrical engineering, **graphite electrode connectors** play a pivotal role in enhancing performance, efficiency, and reliability. As industries push for more sustainable and high-performance solutions, the demand for advanced connector technologies has surged. This article will explore

Innovations in Graphite Electrode Connector Technology: What You Need to Know

In the rapidly evolving field of electrical engineering, **graphite electrode connectors** play a pivotal role in enhancing performance, efficiency, and reliability. As industries push for more sustainable and high-performance solutions, the demand for advanced connector technologies has surged. This article will explore the **latest innovations** in graphite electrode connector technology, focusing on their applications, benefits, and future prospects.

Table of Contents

1. Introduction to Graphite Electrode Connectors

2. Historical Context and Evolution of Graphite Connectors

3. Key Innovations in Graphite Electrode Connector Technology

3.1 Enhanced Conductivity and Performance

3.2 Improved Durability and Lifespan

3.3 Eco-Friendly Materials and Manufacturing Processes

4. Applications of Graphite Electrode Connectors

4.1 Industrial Applications

4.2 Automotive Industry

4.3 Energy Sector

5. Benefits of Advanced Graphite Electrode Connectors

6. Future Trends in Graphite Electrode Connector Technology

7. Frequently Asked Questions (FAQs)

8. Conclusion

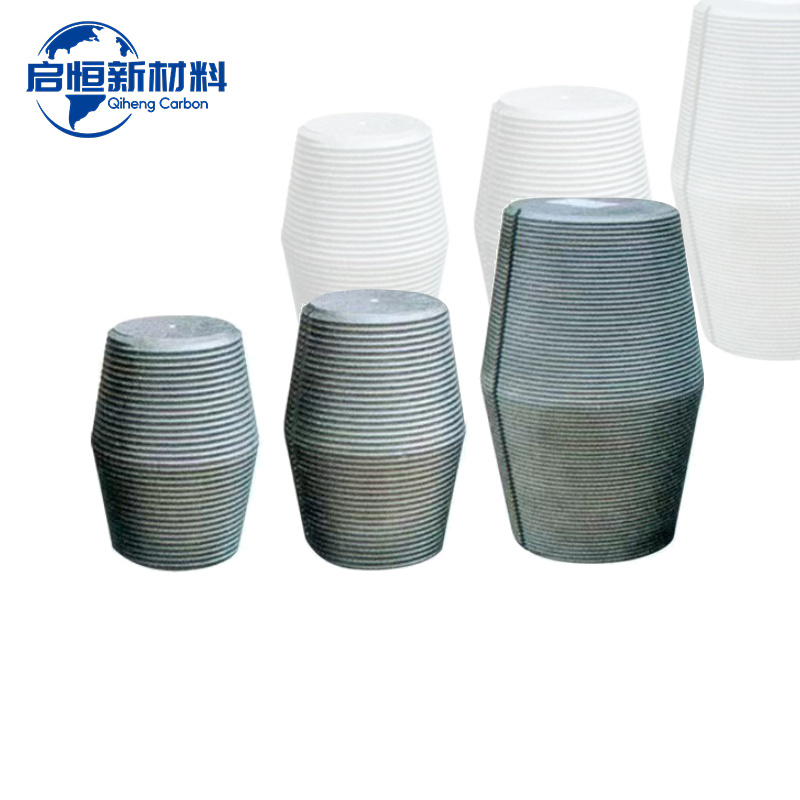

1. Introduction to Graphite Electrode Connectors

Graphite electrode connectors are essential components in various electrical applications, facilitating efficient power transmission. Known for their high **temperature resistance** and **excellent conductivity**, these connectors have become increasingly popular in numerous fields, including **industrial machinery**, **automotive**, and **energy systems**. Understanding these connectors' innovations offers insights into their transformative impact on the industry.

2. Historical Context and Evolution of Graphite Connectors

The use of graphite in electrical applications dates back several decades. Initially, graphite connectors were employed primarily for their **thermal stability** and **conductive properties**. Over the years, advancements in material science and engineering have led to the development of more sophisticated designs. This evolution reflects a broader trend toward sustainability and efficiency in the electrical sector, paving the way for modern innovations.

3. Key Innovations in Graphite Electrode Connector Technology

As technology progresses, several **key innovations** in graphite electrode connectors have emerged, enhancing their performance and applicability.

3.1 Enhanced Conductivity and Performance

Recent advancements have significantly improved the **conductivity** of graphite electrode connectors. By optimizing the composition and structure of the graphite material, manufacturers can achieve lower resistivity and higher thermal conductivity. This improvement translates to better energy efficiency, reducing power losses in electrical systems.

3.2 Improved Durability and Lifespan

Durability is a critical factor in connector technology. Innovations in **coating techniques** and **composite materials** have extended the lifespan of graphite electrode connectors. These enhancements resist wear, corrosion, and thermal degradation, ensuring reliable performance even in the most demanding environments.

3.3 Eco-Friendly Materials and Manufacturing Processes

Sustainability is a growing concern in the electrical industry. New eco-friendly materials and manufacturing processes are being adopted in graphite electrode connector production. These innovations aim to reduce environmental impact while maintaining performance standards. The shift towards **recyclable materials** and **energy-efficient manufacturing** processes is shaping the future of connector technology.

4. Applications of Graphite Electrode Connectors

The versatility of graphite electrode connectors allows their application across various industries. Here are some notable examples:

4.1 Industrial Applications

In industrial settings, graphite electrode connectors are indispensable in heavy machinery and automation. Their ability to withstand high temperatures and corrosive environments makes them ideal for use in manufacturing and processing plants.

4.2 Automotive Industry

The automotive sector is rapidly integrating advanced electrical systems, including electric and hybrid vehicles. Graphite electrode connectors are used in battery management systems, electric motors, and charging infrastructure, helping to enhance the efficiency and reliability of these systems.

4.3 Energy Sector

In renewable energy applications, such as solar and wind power, graphite electrode connectors facilitate efficient power transmission. They are used in inverters, transformers, and grid connections, playing a crucial role in the transition to cleaner energy sources.

5. Benefits of Advanced Graphite Electrode Connectors

The advancements in graphite electrode connector technology provide numerous benefits, including:

- **Increased Efficiency**: Enhanced conductivity leads to reduced energy losses in electrical systems.

- **Longevity**: Improved materials and designs result in longer-lasting connectors, reducing replacement costs and downtime.

- **Sustainability**: Eco-friendly manufacturing processes and materials contribute to a reduced environmental footprint.

- **Versatility**: Suitable for various applications across multiple industries, making them a flexible choice for engineers.

6. Future Trends in Graphite Electrode Connector Technology

Looking ahead, several trends are expected to shape the future of graphite electrode connector technology:

1. **Smart Connectors**: The integration of IoT technology is likely to lead to the development of smart connectors that monitor performance and provide data analytics for predictive maintenance.

2. **Advanced Materials**: Research into new composite materials will continue, potentially leading to connectors that are lighter, stronger, and more conductive.

3. **Customization**: As industries become more specialized, there will be a growing demand for customized connector solutions tailored to specific applications.

7. Frequently Asked Questions (FAQs)

Q1: What are graphite electrode connectors used for?

A1: Graphite electrode connectors are primarily used in electrical applications requiring high conductivity and temperature resistance, including industrial machinery, automotive systems, and renewable energy applications.

Q2: How do advanced graphite electrode connectors improve efficiency?

A2: Enhanced conductivity reduces energy losses in electrical systems, leading to increased overall efficiency. Improved materials also contribute to longevity and reliability.

Q3: Are graphite electrode connectors eco-friendly?

A3: Yes, many manufacturers are adopting eco-friendly materials and sustainable manufacturing processes to reduce the environmental impact of graphite electrode connectors.

Q4: What industries benefit from graphite electrode connectors?

A4: Industries such as manufacturing, automotive, and energy are among the primary beneficiaries of advanced graphite electrode connector technology.

Q5: What is the future of graphite electrode connector technology?

A5: The future trends include the integration of smart technology, the development of advanced materials, and increased customization to meet specific industry needs.

8. Conclusion

Innovations in graphite electrode connector technology are reshaping the landscape of the electrical industry. With enhanced conductivity, improved durability, and a focus on sustainability, these connectors are poised to become even more integral to various applications. As we look to the future, the continued evolution of this technology promises to bring about significant advancements, ensuring that industries can meet the growing demands for efficiency and reliability in their electrical systems. Embracing these innovations will not only enhance performance but also contribute to a more sustainable and efficient energy future.

Focus On Hot Spots

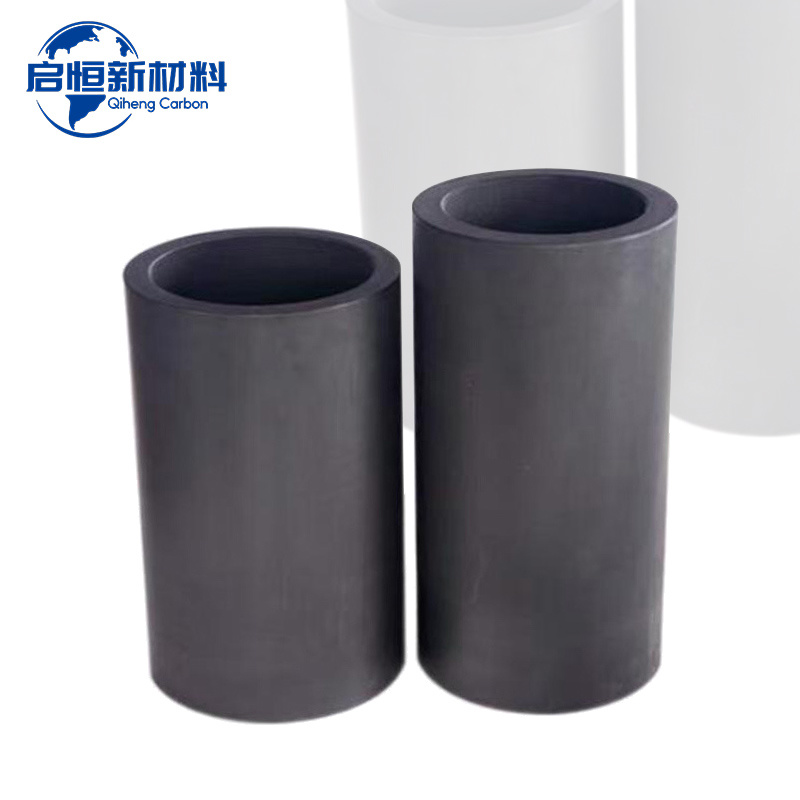

Understanding the Lifecycle of a Graphite Crucible: From Creation to Application

Understanding the Lifecycle of a Graphite Crucible

Graphite crucibles are essential tools widely used in various industrial applications, particularly in metallurgy. Their unique properties, such as high thermal conductivity and resistance to thermal shock, make them indispensable for melting metals and other applications. In this article, we will delve into the lifecycle of a graphite crucible, e

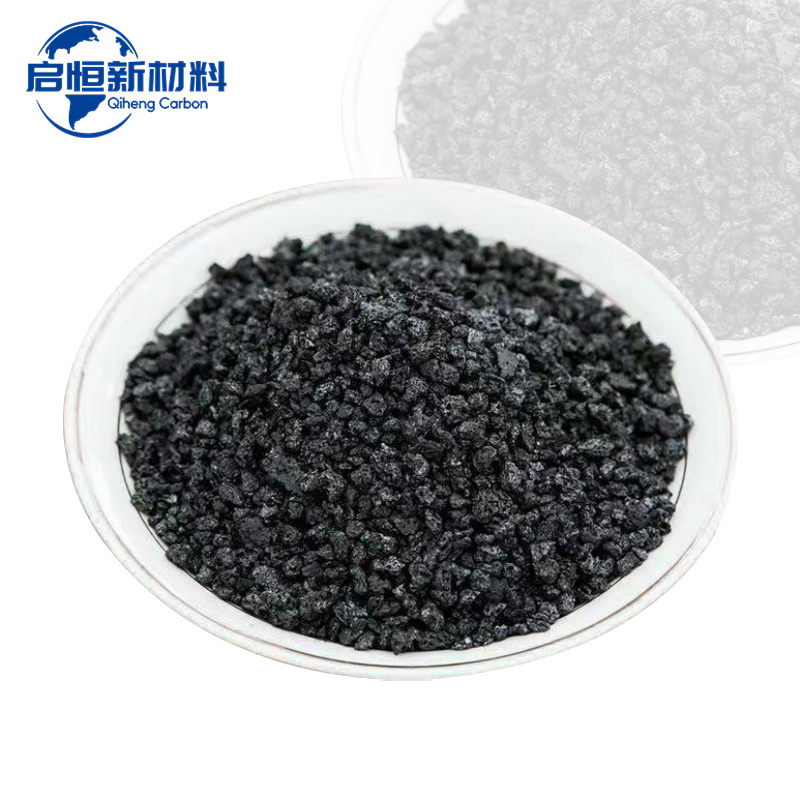

Understanding Calcined Petroleum Coke: Properties, Applications, and Benefits

Calcined petroleum coke (CPC) is a carbonaceous solid material derived from the thermal processing of green petroleum coke, which is produced during the oil refining process. The calcination process involves heating green petroleum coke to high temperatures (approximately 1200°C to 1400°C) in a controlled atmosphere, which drives off volatile compounds and enhances the carbon content, resulting in