The Benefits of Using Graphite Crucibles in Foundries: Unveiling the Advantages for Optimal Metal Melting

Summary:

The Benefits of Using Graphite Crucibles in Foundries

Foundries play a crucial role in metalworking, shaping raw materials into finished products. Among the essential tools in this process, graphite crucibles stand out for their unique properties. In this article, we delve into the numerous benefits of using graphite crucibles in foundries, examining their impact on efficiency, cost-effectiveness,

The Benefits of Using Graphite Crucibles in Foundries

Foundries play a crucial role in metalworking, shaping raw materials into finished products. Among the essential tools in this process, graphite crucibles stand out for their unique properties. In this article, we delve into the numerous benefits of using graphite crucibles in foundries, examining their impact on efficiency, cost-effectiveness, and overall metal quality.

Table of Contents

1. Introduction to Graphite Crucibles in Foundries

2. Key Properties of Graphite Crucibles

- Exceptional Thermal Conductivity

- Outstanding Chemical Resistance

- High Durability and Longevity

3. Applications of Graphite Crucibles in Foundries

4. Advantages of Using Graphite Crucibles

- Cost Efficiency

- Improved Metal Quality

- Energy Savings

5. Types of Graphite Crucibles

- Standard Graphite Crucibles

- Isostatic Graphite Crucibles

6. Manufacturing Graphite Crucibles

7. Proper Handling and Care for Graphite Crucibles

8. Conclusion

9. FAQs

Introduction to Graphite Crucibles in Foundries

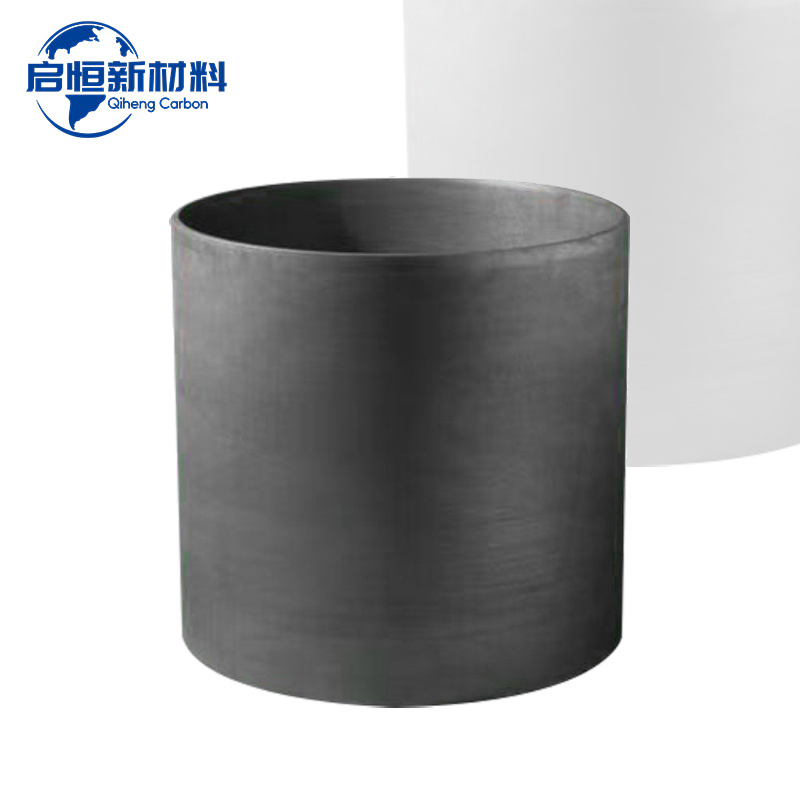

In the realm of metal casting, **graphite crucibles** serve as indispensable tools. Their ability to withstand high temperatures and corrosive environments makes them ideal for melting metals, including aluminum, gold, and silver. Foundries frequently utilize these crucibles due to their exceptional properties, which enhance both productivity and the quality of the final product. Understanding the benefits of graphite crucibles can help foundries make informed choices and improve their operations.

Key Properties of Graphite Crucibles

Graphite crucibles possess several key properties that contribute to their effectiveness in metal melting. Below are the primary characteristics that set these crucibles apart from other materials.

Exceptional Thermal Conductivity

One of the most significant advantages of graphite crucibles is their **high thermal conductivity**. This property enables them to conduct heat efficiently, allowing for faster melting of metals. The rapid heat transfer minimizes energy consumption, leading to lower operational costs and improved turnaround times in foundries.

Outstanding Chemical Resistance

Graphite is renowned for its **chemical resistance**, making it suitable for melting various metal alloys. The inert nature of graphite prevents unwanted reactions with the metals being melted, ensuring the integrity of the final product. This characteristic is particularly beneficial in foundries dealing with reactive metals that require careful handling.

High Durability and Longevity

Another critical property of graphite crucibles is their **durability**. These crucibles can withstand extreme temperatures and thermal shocks, which are common during intense metal melting processes. As a result, graphite crucibles have a longer lifespan compared to other materials, reducing the frequency of replacement and maintenance costs.

Applications of Graphite Crucibles in Foundries

Graphite crucibles are used in a variety of applications within foundries. They are primarily employed for melting metals, but their versatility extends to several other functions:

- **Metal Melting**: Used for melting ferrous and non-ferrous metals.

- **Alloy Production**: Ideal for producing metal alloys due to their non-reactive nature.

- **Casting Processes**: Crucibles are essential in casting operations, providing a reliable vessel for molten metals.

- **Laboratory Research**: Used in metallurgical laboratories for experiments and testing.

Advantages of Using Graphite Crucibles

The benefits of using graphite crucibles in foundries are multifaceted. Below, we highlight some of the most significant advantages that make them indispensable.

Cost Efficiency

Using graphite crucibles can lead to **significant cost savings** for foundries. Their long lifespan reduces the need for frequent replacements, while their high thermal efficiency lowers energy consumption. These factors collectively lead to a more cost-effective melting process.

Improved Metal Quality

Graphite crucibles contribute to producing higher-quality metal castings. Their resistance to chemical reactions ensures that the metal remains pure, free from contamination. This results in superior casting quality, which is vital for industries requiring precise specifications and standards.

Energy Savings

The **energy efficiency** of graphite crucibles is another compelling advantage. By providing excellent thermal conductivity, they allow for reduced melting times, translating into lower energy usage. This not only benefits the environment but also enhances the overall sustainability of foundry operations.

Types of Graphite Crucibles

When selecting a graphite crucible, it is essential to consider the types available to meet specific foundry needs. Below are two common types of graphite crucibles.

Standard Graphite Crucibles

Standard graphite crucibles are widely used in foundries for general melting applications. They come in various sizes and shapes, accommodating different metal types and batch sizes. Their cost-effectiveness and versatility make them a popular choice.

Isostatic Graphite Crucibles

Isostatic graphite crucibles are manufactured using a unique process that enhances their density and strength. They are designed for high-performance applications, often used for melting high-value metals or alloys. Their superior properties make them ideal for demanding foundry environments.

Manufacturing Graphite Crucibles

The manufacturing process of graphite crucibles involves several stages to ensure quality and performance. High-purity graphite is mixed with a binder and then subjected to high temperatures to achieve the desired shape and density. The production process may vary depending on the type of crucible being manufactured, but quality control remains a priority to ensure consistency and reliability.

Proper Handling and Care for Graphite Crucibles

To maximize the lifespan and performance of graphite crucibles, proper handling and care are essential. Here are some key practices:

- **Avoid Thermal Shock**: Gradually heat and cool the crucibles to prevent cracking.

- **Store Safely**: Store in a dry environment to prevent moisture absorption.

- **Regular Inspection**: Check for wear and damage regularly to identify issues early.

Conclusion

In conclusion, graphite crucibles offer a multitude of benefits that significantly enhance foundry operations. Their exceptional thermal conductivity, chemical resistance, and durability make them the preferred choice for metal melting and casting processes. By choosing graphite crucibles, foundries can achieve cost efficiency, improved metal quality, and energy savings, ultimately leading to more sustainable operations. As the industry continues to evolve, the importance of these crucibles will only grow, solidifying their place as a vital component in metalworking.

FAQs

1. What are graphite crucibles used for in foundries?

Graphite crucibles are primarily used for melting ferrous and non-ferrous metals, producing metal alloys, and casting processes.

2. How do graphite crucibles compare to other materials?

Graphite crucibles are superior due to their high thermal conductivity, chemical resistance, and durability, making them more effective for metal melting.

3. Why are energy savings important in foundries?

Energy savings reduce operational costs and contribute to sustainability by minimizing environmental impact.

4. What types of metals can be melted in graphite crucibles?

Graphite crucibles can melt a wide range of metals, including aluminum, gold, silver, and various alloys.

5. How can I extend the life of my graphite crucibles?

To extend the life of graphite crucibles, avoid thermal shocks, store them properly, and conduct regular inspections for wear and damage.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property