Understanding Calcined Petroleum Coke: Properties, Uses, and Benefits

Summary:

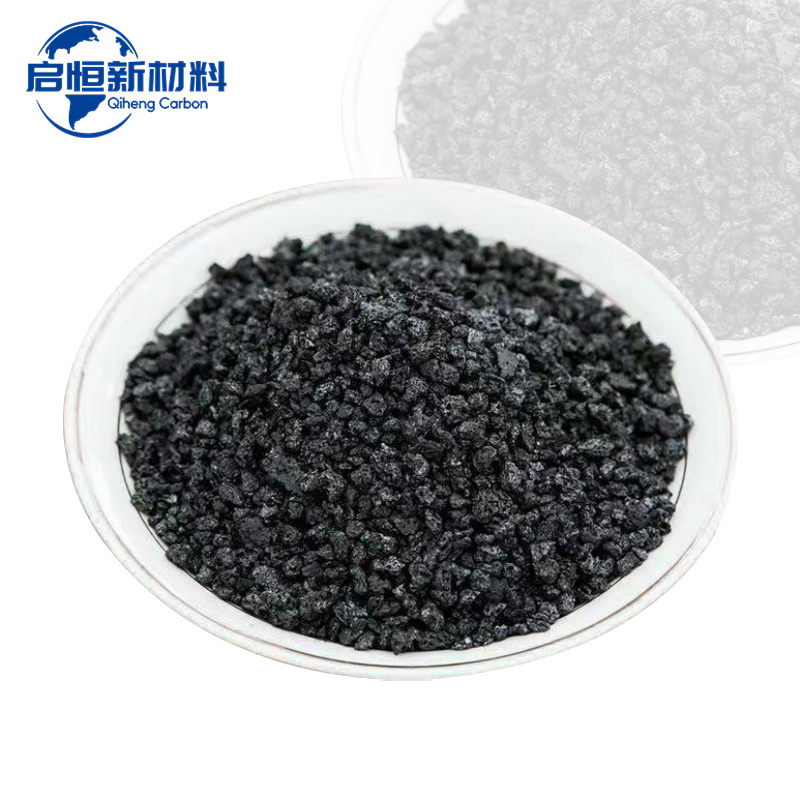

Calcined petroleum coke (CPC) is produced by heating green petroleum coke in a rotary kiln to temperatures exceeding 1,200 degrees Celsius. This thermal treatment removes volatile compounds, resulting in a dense, carbon-rich material with unique properties. The calcination process leads to significant changes in the physical and chemical characteristics of petroleum coke, making it suitable for va

Calcined petroleum coke (CPC) is produced by heating green petroleum coke in a rotary kiln to temperatures exceeding 1,200 degrees Celsius. This thermal treatment removes volatile compounds, resulting in a dense, carbon-rich material with unique properties. The calcination process leads to significant changes in the physical and chemical characteristics of petroleum coke, making it suitable for various industrial applications.

One of the primary uses of calcined petroleum coke is in the aluminum industry. It serves as a key ingredient in the production of anodes, which are essential for the electrolysis process in aluminum smelting. Due to its high carbon content and low impurities, CPC enhances the efficiency of aluminum production, leading to higher yields and energy savings. Moreover, its stability and conductivity make it an ideal choice for this application.

In addition to the aluminum sector, calcined petroleum coke is also widely used in the manufacturing of graphite electrodes. These electrodes are crucial for electric arc furnaces, which are commonly used in steel production. The high thermal conductivity and low reactivity of CPC contribute to the performance and longevity of graphite electrodes, making them indispensable in the steelmaking process.

Furthermore, calcined petroleum coke finds applications in the production of titanium dioxide and in the creation of specialty carbon products. Its unique properties allow it to be utilized as a filler or additive in various chemical processes, enhancing the performance of end products. The versatility of CPC makes it an attractive option for manufacturers looking to improve product quality and reduce costs.

Another important aspect of calcined petroleum coke is its environmental impact. As industries seek to reduce their carbon footprint, CPC has emerged as a more sustainable alternative compared to other carbon sources. Its production process is designed to minimize emissions, and when used in industrial applications, it contributes to improved energy efficiency and reduced waste.

In summary, calcined petroleum coke is a vital material in several industries due to its unique properties and benefits. Its role in aluminum smelting, graphite electrode production, and various chemical processes highlights its importance in modern manufacturing. As the demand for sustainable materials increases, CPC stands out as a valuable resource, contributing to both economic and environmental goals. Understanding the properties and applications of calcined petroleum coke can help businesses make informed decisions about its use in their operations.

One of the primary uses of calcined petroleum coke is in the aluminum industry. It serves as a key ingredient in the production of anodes, which are essential for the electrolysis process in aluminum smelting. Due to its high carbon content and low impurities, CPC enhances the efficiency of aluminum production, leading to higher yields and energy savings. Moreover, its stability and conductivity make it an ideal choice for this application.

In addition to the aluminum sector, calcined petroleum coke is also widely used in the manufacturing of graphite electrodes. These electrodes are crucial for electric arc furnaces, which are commonly used in steel production. The high thermal conductivity and low reactivity of CPC contribute to the performance and longevity of graphite electrodes, making them indispensable in the steelmaking process.

Furthermore, calcined petroleum coke finds applications in the production of titanium dioxide and in the creation of specialty carbon products. Its unique properties allow it to be utilized as a filler or additive in various chemical processes, enhancing the performance of end products. The versatility of CPC makes it an attractive option for manufacturers looking to improve product quality and reduce costs.

Another important aspect of calcined petroleum coke is its environmental impact. As industries seek to reduce their carbon footprint, CPC has emerged as a more sustainable alternative compared to other carbon sources. Its production process is designed to minimize emissions, and when used in industrial applications, it contributes to improved energy efficiency and reduced waste.

In summary, calcined petroleum coke is a vital material in several industries due to its unique properties and benefits. Its role in aluminum smelting, graphite electrode production, and various chemical processes highlights its importance in modern manufacturing. As the demand for sustainable materials increases, CPC stands out as a valuable resource, contributing to both economic and environmental goals. Understanding the properties and applications of calcined petroleum coke can help businesses make informed decisions about its use in their operations.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property