Why Graphite Electrode Connectors are Essential for Heavy-Duty Applications

Why Graphite Electrode Connectors are Essential for Heavy-Duty Applications

Table of Contents

- 1. Introduction to Graphite Electrode Connectors

- 2. What Are Graphite Electrode Connectors?

- 3. Importance of Graphite Electrode Connectors in Heavy-Duty Applications

- 4. Key Advantages of Using Graphite Electrode Connectors

- 5. Applications of Graphite Electrode Connectors

- 6. Materials and Technology Behind Graphite Electrode Connectors

- 7. Installation and Maintenance of Graphite Electrode Connectors

- 8. Future Trends in Graphite Electrode Connector Technology

- 9. FAQs About Graphite Electrode Connectors

- 10. Conclusion

1. Introduction to Graphite Electrode Connectors

In the industrial landscape, the demand for reliable and efficient electrical connections is paramount. **Graphite electrode connectors** have emerged as a vital component in heavy-duty applications, particularly in environments requiring high conductivity and heat resistance. This article provides an in-depth analysis of why these connectors are essential, their unique properties, and their growing significance across various industries.

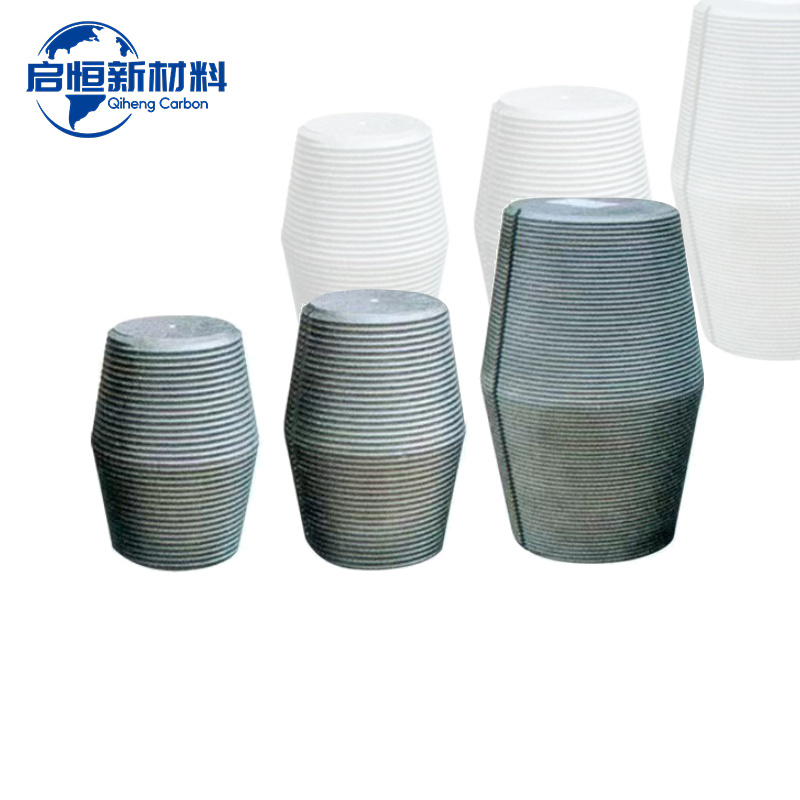

2. What Are Graphite Electrode Connectors?

Graphite electrode connectors are specialized connectors designed to facilitate electrical connections in heavy-duty applications, particularly in electrical arc furnaces and related equipment. Made primarily from **graphite**—a material known for its excellent electrical conductivity and thermal properties—these connectors can withstand extreme conditions, making them ideal for industries such as metallurgy, construction, and manufacturing.

3. Importance of Graphite Electrode Connectors in Heavy-Duty Applications

The importance of graphite electrode connectors cannot be overstated. They play a critical role in ensuring that electrical currents flow efficiently, which is especially crucial in high-load scenarios. These connectors help to mitigate the risks of overheating and electrical failures, which can lead to costly downtime and equipment damage.

Enhanced Electrical Conductivity

Graphite is an excellent conductor of electricity. The use of graphite electrode connectors ensures that electrical currents are transmitted with minimal resistance, thereby enhancing the overall efficiency of heavy-duty machinery.

Temperature Resistance

In heavy-duty applications, equipment often operates under extreme temperatures. Graphite's inherent thermal stability allows these connectors to maintain their integrity and performance, even in challenging environments.

Durability and Longevity

Graphite electrode connectors are designed to last. Their robust construction helps them withstand the wear and tear of heavy use, making them a cost-effective choice for industries that rely on continuous operation.

4. Key Advantages of Using Graphite Electrode Connectors

Adopting graphite electrode connectors provides several advantages that make them a preferred choice in industrial applications.

Low Maintenance Requirements

Unlike traditional metal connectors, graphite electrode connectors require minimal maintenance. Their durability means that they are less prone to corrosion and wear, which translates to lower operational costs.

Lightweight Design

The lightweight nature of graphite makes these connectors easier to handle and install. This feature is particularly beneficial in applications where weight is a critical factor.

Versatility in Applications

Graphite electrode connectors are highly versatile and can be tailored to meet the specific needs of various industries, from steel manufacturing to automotive production.

5. Applications of Graphite Electrode Connectors

Graphite electrode connectors find applications in numerous sectors due to their unique properties.

Metallurgical Industry

In the metallurgical industry, these connectors are essential for the operation of electric arc furnaces, where they facilitate the melting of metals. High conductivity and reliability are crucial in these applications to maintain production efficiency.

Manufacturing Equipment

From heavy machinery to assembly lines, graphite electrode connectors are used in manufacturing equipment to ensure consistent power delivery and operation.

Energy Sector

The energy sector leverages graphite electrode connectors in power generation and distribution systems, where their ability to handle high currents efficiently is vital.

6. Materials and Technology Behind Graphite Electrode Connectors

The technology involved in manufacturing graphite electrode connectors has advanced significantly, enhancing their performance and reliability.

High-Quality Graphite

The quality of graphite used in these connectors directly impacts their performance. High-purity graphite is often selected to ensure optimal conductivity and mechanical strength.

Advanced Manufacturing Techniques

Modern manufacturing techniques, such as precision molding and machining, allow for the production of connectors that meet stringent industry standards. These processes ensure consistent quality and performance in every connector produced.

7. Installation and Maintenance of Graphite Electrode Connectors

Proper installation and maintenance are essential for maximizing the performance of graphite electrode connectors.

Installation Guidelines

When installing graphite electrode connectors, it’s important to follow manufacturer guidelines closely. A secure and well-aligned installation ensures optimal conductivity and minimizes the risk of failure.

Maintenance Practices

Regular inspections should be conducted to check for any signs of wear or damage. While graphite connectors are low maintenance, keeping them clean and free from debris can enhance their longevity.

8. Future Trends in Graphite Electrode Connector Technology

The landscape for graphite electrode connectors is continuously evolving, with innovations that promise to enhance their functionality and application.

Enhanced Materials

Research into composite materials and advanced graphite formulations may lead to even more durable and efficient connectors, tailored for specific applications.

Smart Technology Integration

The integration of smart technology, including sensors and monitoring systems, is a potential future trend. This technology could provide real-time data on connector performance, helping to preemptively address issues before they lead to failures.

9. FAQs About Graphite Electrode Connectors

What industries use graphite electrode connectors?

Graphite electrode connectors are utilized in various industries, including the metallurgical, manufacturing, and energy sectors, due to their high conductivity and durability.

How do graphite electrode connectors compare to traditional metal connectors?

Graphite connectors offer superior electrical conductivity, lower maintenance, and enhanced thermal resistance compared to traditional metal connectors, making them a more reliable option for heavy-duty applications.

Can graphite electrode connectors be customized?

Yes, graphite electrode connectors can be customized to meet the specific requirements of different applications, including size, shape, and electrical specifications.

What are the signs of wear in graphite electrode connectors?

Signs of wear may include physical damage, discoloration, or changes in conductivity. Regular inspections help identify these issues early.

How can I ensure the longevity of graphite electrode connectors?

To ensure longevity, install connectors according to manufacturer guidelines, perform regular maintenance, and keep them clean and free of debris.

10. Conclusion

In summary, **graphite electrode connectors** are indispensable components in heavy-duty applications. Their exceptional conductivity, temperature resistance, and durability make them a preferred choice across various industries. As technology continues to advance, the role of these connectors is poised to expand further, solidifying their importance in the industrial landscape. By understanding their benefits and applications, businesses can enhance operational efficiency and reliability, ensuring a competitive edge in their respective sectors.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries