Understanding Graphite Blocks: Key Insights for the Metallurgical and Energy Industry

Summary:

Graphite blocks are a critical component in various applications within the metallurgical and energy sectors due to their unique properties. These blocks are primarily made from natural or synthetic graphite, known for their excellent thermal conductivity, resistance to high temperatures, and low electrical resistance. As a result, they play a pivotal role in numerous industrial applications, from

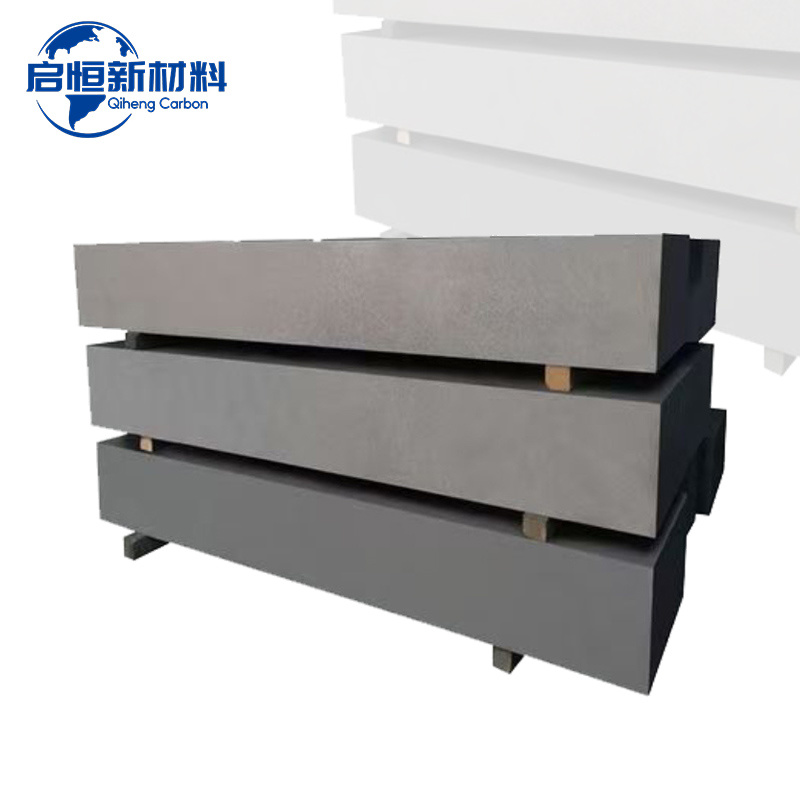

Graphite blocks are a critical component in various applications within the metallurgical and energy sectors due to their unique properties. These blocks are primarily made from natural or synthetic graphite, known for their excellent thermal conductivity, resistance to high temperatures, and low electrical resistance. As a result, they play a pivotal role in numerous industrial applications, from electric arc furnaces to battery production.

One of the most significant uses of graphite blocks is in the metallurgy industry, particularly in the production of iron and steel. They are widely utilized as lining materials in electric arc furnaces, where they withstand extreme temperatures and facilitate efficient energy transfer. Their ability to maintain structural integrity under stress makes them an ideal choice for high-performance applications. Additionally, the use of graphite blocks can help improve the overall efficiency of the melting process, resulting in better-quality steel and reduced energy consumption.

In the energy sector, graphite blocks are increasingly being used in the manufacturing of batteries, particularly lithium-ion batteries. These batteries rely on graphite for their anodes, which are crucial for energy storage and transfer. The high electrical conductivity of graphite blocks ensures that batteries operate at optimal efficiency, leading to longer life cycles and improved performance. As the demand for renewable energy sources continues to rise, the need for efficient energy storage solutions will further drive the market for graphite blocks.

The manufacturing process of graphite blocks typically involves the compaction of fine graphite powder followed by a high-temperature treatment to create a solid and durable product. This process can vary depending on the specific requirements of the application, such as density and purity levels. It’s essential to select the appropriate manufacturing technique to ensure that the final product meets the desired specifications for performance and longevity.

In conclusion, graphite blocks represent a vital resource in the metallurgical and energy industries, offering unique properties that enhance operational efficiency. Their applications continue to evolve, driven by advancements in technology and growing demands for sustainable energy solutions. By understanding the characteristics and potential uses of graphite blocks, stakeholders in these industries can make informed decisions to optimize their processes and product offerings. As the market evolves, staying informed about the latest developments in graphite technology will be crucial for maintaining a competitive edge.

One of the most significant uses of graphite blocks is in the metallurgy industry, particularly in the production of iron and steel. They are widely utilized as lining materials in electric arc furnaces, where they withstand extreme temperatures and facilitate efficient energy transfer. Their ability to maintain structural integrity under stress makes them an ideal choice for high-performance applications. Additionally, the use of graphite blocks can help improve the overall efficiency of the melting process, resulting in better-quality steel and reduced energy consumption.

In the energy sector, graphite blocks are increasingly being used in the manufacturing of batteries, particularly lithium-ion batteries. These batteries rely on graphite for their anodes, which are crucial for energy storage and transfer. The high electrical conductivity of graphite blocks ensures that batteries operate at optimal efficiency, leading to longer life cycles and improved performance. As the demand for renewable energy sources continues to rise, the need for efficient energy storage solutions will further drive the market for graphite blocks.

The manufacturing process of graphite blocks typically involves the compaction of fine graphite powder followed by a high-temperature treatment to create a solid and durable product. This process can vary depending on the specific requirements of the application, such as density and purity levels. It’s essential to select the appropriate manufacturing technique to ensure that the final product meets the desired specifications for performance and longevity.

In conclusion, graphite blocks represent a vital resource in the metallurgical and energy industries, offering unique properties that enhance operational efficiency. Their applications continue to evolve, driven by advancements in technology and growing demands for sustainable energy solutions. By understanding the characteristics and potential uses of graphite blocks, stakeholders in these industries can make informed decisions to optimize their processes and product offerings. As the market evolves, staying informed about the latest developments in graphite technology will be crucial for maintaining a competitive edge.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property