How to Troubleshoot Common Issues with UHP Graphite Electrodes: A Complete Guide

Summary:

How to Troubleshoot Common Issues with UHP Graphite Electrodes

Table of Contents

1. Understanding UHP Graphite Electrodes

2. Common Issues with UHP Graphite Electrodes

3. Identifying and Diagnosing Problems

4. Effective Troubleshooting Techniques

4.1. Addressing Surface Defects

4.2. Solving Electrical Resistance Issues

4.3. Handling Thermal Conductivity Problems

5. Maintenance Practices for UHP Gr

How to Troubleshoot Common Issues with UHP Graphite Electrodes

Table of Contents

1. Understanding UHP Graphite Electrodes

2. Common Issues with UHP Graphite Electrodes

3. Identifying and Diagnosing Problems

4. Effective Troubleshooting Techniques

4.1. Addressing Surface Defects

4.2. Solving Electrical Resistance Issues

4.3. Handling Thermal Conductivity Problems

5. Maintenance Practices for UHP Graphite Electrodes

6. Frequently Asked Questions (FAQs)

7. Conclusion

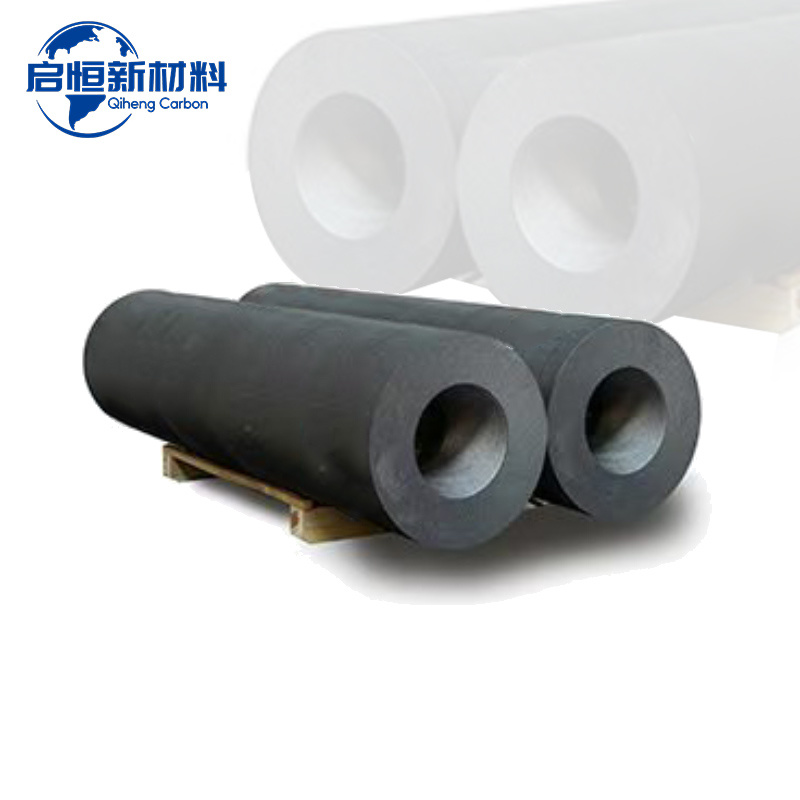

1. Understanding UHP Graphite Electrodes

Ultra-High Power (UHP) graphite electrodes are crucial for various industrial applications, particularly in electric arc furnaces for steelmaking. These electrodes provide the necessary electrical resistance and thermal conductivity required to melt scrap metal efficiently. Their ability to withstand extreme temperatures and harsh operational conditions makes them indispensable in the metallurgy sector. However, like any industrial component, UHP graphite electrodes can experience issues that affect their performance. Understanding the composition, properties, and applications of these electrodes is the first step in troubleshooting any problems.

2. Common Issues with UHP Graphite Electrodes

When using UHP graphite electrodes, users may encounter several common challenges, including:

- **Surface defects**: Cracks, pits, or inconsistent surfaces can compromise performance.

- **Electrical resistance issues**: Increased resistance can lead to inefficiencies and overheating.

- **Thermal conductivity problems**: Reduced thermal conductivity can affect the melting process and energy consumption.

- **Wear and tear**: Excessive wear can shorten electrode life and increase operational costs.

Recognizing these issues early is critical to minimizing downtime and maintaining production efficiency.

3. Identifying and Diagnosing Problems

Before implementing troubleshooting techniques, it's essential to accurately identify the problem. Here are key steps to diagnose issues with UHP graphite electrodes:

- **Visual Inspection**: Conduct a thorough visual examination of the electrodes before and after use. Look for signs of wear, cracks, or contamination. Document any abnormalities for future reference.

- **Performance Monitoring**: Track the performance metrics of the electrodes during operation. Monitor parameters such as temperature, power consumption, and melting efficiency to identify deviations from normal performance levels.

- **Conductivity Testing**: Use specialized equipment to measure electrical conductivity. This will help in diagnosing any resistance issues that may be impacting performance.

By systematically identifying problems, users can better understand the underlying causes and apply appropriate troubleshooting measures.

4. Effective Troubleshooting Techniques

Once the problems are identified, users can implement specific troubleshooting techniques to resolve the issues effectively.

4.1. Addressing Surface Defects

Surface defects such as cracks or pits can significantly impede the performance of UHP graphite electrodes. Here are some strategies to address these issues:

- **Surface Repair**: For minor defects, consider using specialized repair compounds designed for graphite materials. These compounds can fill gaps and restore surface integrity.

- **Electrode Replacement**: If defects are extensive, replacing the electrode may be the most viable option. Always choose high-quality electrodes from reputable suppliers to ensure consistency and reliability.

4.2. Solving Electrical Resistance Issues

Electrical resistance problems can lead to overheating and increased energy costs. To troubleshoot these issues:

- **Connection Inspection**: Check all electrical connections for signs of wear or corrosion. Ensure that connections are clean and secure to minimize resistance.

- **Regular Calibration**: Regularly calibrate equipment used to monitor electrical performance. This ensures accurate measurements and helps in early detection of resistance issues.

4.3. Handling Thermal Conductivity Problems

Thermal conductivity problems can arise from poor-quality materials or improper handling. To mitigate these issues:

- **Material Quality**: Always source UHP graphite electrodes from trusted manufacturers who adhere to stringent quality control measures. High-quality materials enhance thermal conductivity.

- **Proper Handling**: Implement best practices for handling and storing electrodes to prevent damage that could compromise thermal properties. Avoid exposing the electrodes to extreme temperatures when not in use.

5. Maintenance Practices for UHP Graphite Electrodes

Preventive maintenance is key to maximizing the lifespan and performance of UHP graphite electrodes. Consider these practices:

- **Regular Inspections**: Schedule routine inspections to monitor the condition of electrodes and identify any potential issues before they escalate.

- **Cleaning Procedures**: Establish a cleaning routine to remove contaminants from the electrode surface. This can help maintain optimal conductivity and temperature regulation.

- **Training Personnel**: Ensure that all personnel handling UHP graphite electrodes are adequately trained in best practices, including safe handling and maintenance procedures.

By adopting these maintenance practices, users can significantly reduce the likelihood of encountering issues with UHP graphite electrodes.

6. Frequently Asked Questions (FAQs)

What are UHP graphite electrodes used for?

UHP graphite electrodes are primarily used in electric arc furnaces for steelmaking, as they provide the necessary electrical and thermal properties for efficient metal melting.

How can I tell if my UHP graphite electrodes are damaged?

Signs of damage include visible cracks, surface irregularities, and reduced performance metrics such as increased electrical resistance or decreased melting efficiency.

What should I do if my electrodes are overheating?

First, check all electrical connections for issues. If the problem persists, inspect the electrodes for surface defects or consider replacing them if necessary.

How often should I perform maintenance on my UHP graphite electrodes?

Regular maintenance should be performed based on usage frequency. A routine inspection every few weeks is advisable, with more frequent checks during high production periods.

Can I repair damaged UHP graphite electrodes?

Minor surface defects can often be repaired using specialized repair compounds. However, extensive damage may require replacement of the electrodes.

7. Conclusion

Troubleshooting common issues with UHP graphite electrodes requires a systematic approach that includes understanding the product, identifying problems, and implementing effective solutions. By adopting best practices for maintenance and addressing issues promptly, users can ensure optimal performance and longevity of their electrodes. This not only minimizes downtime but also enhances overall operational efficiency, ultimately leading to cost savings and improved production outcomes. Employ these strategies to effectively troubleshoot and maintain your UHP graphite electrodes, and you will see a positive impact on your operations.

Previous:

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property