Understanding the Role of Graphite Crucibles in Metal Casting

Summary:

Understanding the Role of Graphite Crucibles in Metal Casting

Table of Contents

1. Introduction to Graphite Crucibles

2. What Are Graphite Crucibles?

2.1 Composition of Graphite Crucibles

2.2 Types of Graphite Crucibles

3. Properties of Graphite Crucibles

3.1 Thermal Conductivity

3.2 Resistance to Thermal Shock

3.3 Corrosion Resistance

4. Advantages of Using Graphite Crucibles in Metal Casting

4.1

Understanding the Role of Graphite Crucibles in Metal Casting

Table of Contents

1. Introduction to Graphite Crucibles

2. What Are Graphite Crucibles?

2.1 Composition of Graphite Crucibles

2.2 Types of Graphite Crucibles

3. Properties of Graphite Crucibles

3.1 Thermal Conductivity

3.2 Resistance to Thermal Shock

3.3 Corrosion Resistance

4. Advantages of Using Graphite Crucibles in Metal Casting

4.1 High Melting Point

4.2 Energy Efficiency

4.3 Versatility in Applications

5. Applications of Graphite Crucibles in Different Industries

5.1 Jewelry and Precious Metal Casting

5.2 Aerospace and Automotive Components

6. How to Choose the Right Graphite Crucible

6.1 Factors to Consider

6.2 Quality Standards

7. Maintenance and Care for Graphite Crucibles

7.1 Cleaning Procedures

7.2 Storage Tips

8. Frequently Asked Questions (FAQs)

9. Conclusion

1. Introduction to Graphite Crucibles

Graphite crucibles play an essential role in the metal casting industry, serving as a reliable vessel for melting metals and alloys. Their unique properties make them a preferred choice for various applications, particularly where high temperatures and chemical resistance are required. In this article, we will explore the significance of graphite crucibles, their properties, advantages, and how they contribute to efficient metal casting processes.

2. What Are Graphite Crucibles?

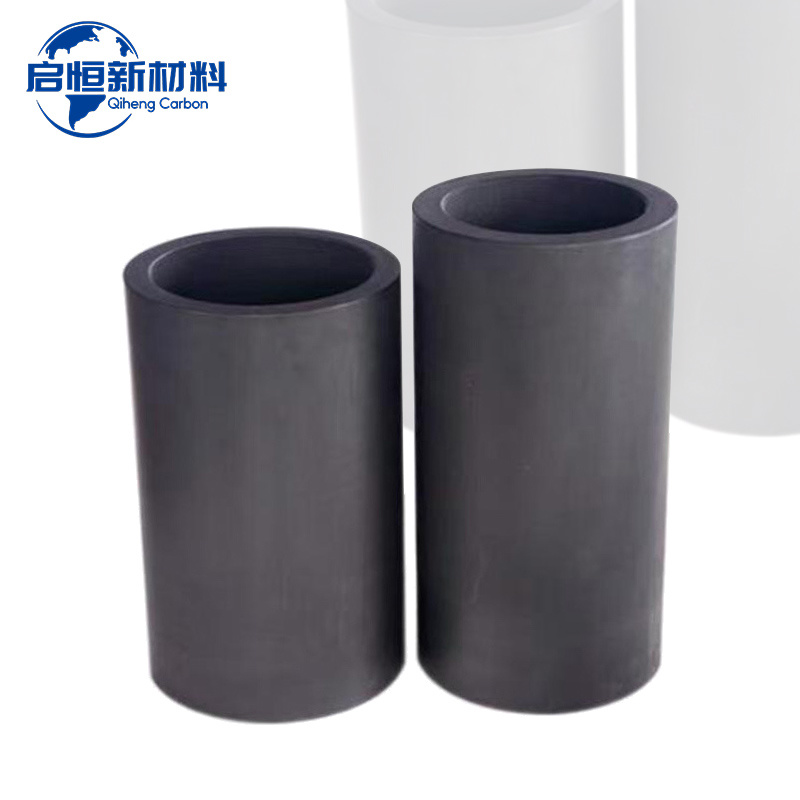

Graphite crucibles are specialized containers crafted primarily from graphite, designed to withstand extreme temperatures and provide excellent thermal conductivity. They are utilized in the casting of metals by melting materials at high temperatures before pouring them into molds.

2.1 Composition of Graphite Crucibles

The composition of graphite crucibles typically includes natural or synthetic graphite blended with various additives to enhance performance. These materials are combined in precise ratios to produce crucibles that can withstand specific melting temperatures and resist chemical reactions with molten metals.

2.2 Types of Graphite Crucibles

There are several types of graphite crucibles available, each tailored for specific applications. Common types include:

- **High-purity graphite crucibles**: Ideal for precious metals due to their low reactivity.

- **Silicon carbide crucibles**: Known for their durability, suitable for high-temperature applications.

- **Clay-graphite crucibles**: Affordable options for general metal casting.

3. Properties of Graphite Crucibles

Understanding the properties of graphite crucibles is crucial for their effective use in metal casting processes.

3.1 Thermal Conductivity

Graphite crucibles possess exceptional thermal conductivity, allowing for rapid heat transfer. This property ensures that metals melt evenly, reducing the risk of uneven casting and promoting higher quality finishes.

3.2 Resistance to Thermal Shock

One of the standout features of graphite crucibles is their resistance to thermal shock. This means that they can withstand sudden temperature changes without cracking, making them ideal for environments where quick heating and cooling occur.

3.3 Corrosion Resistance

Graphite is inherently resistant to many chemicals, including those found in molten metals. This property extends the lifespan of the crucible and reduces contamination risks, ensuring that the final cast product maintains its intended composition.

4. Advantages of Using Graphite Crucibles in Metal Casting

The utilization of graphite crucibles in metal casting offers several advantages that enhance the overall process.

4.1 High Melting Point

Graphite crucibles can endure high temperatures, often exceeding 3000°F (1640°C). This high melting point allows for the casting of a wide range of metals, including those that require extreme heat for melting.

4.2 Energy Efficiency

Due to their excellent thermal properties, graphite crucibles can help minimize energy consumption during the melting process. The efficient heat retention reduces the need for constant energy input, leading to cost savings for manufacturers.

4.3 Versatility in Applications

Graphite crucibles are versatile and can accommodate various metals and alloys, making them suitable for numerous industries, including jewelry, aerospace, and automotive.

5. Applications of Graphite Crucibles in Different Industries

The adaptability of graphite crucibles allows them to be utilized across different sectors.

5.1 Jewelry and Precious Metal Casting

In the jewelry industry, high-purity graphite crucibles are preferred for melting precious metals such as gold and silver. Their properties ensure minimal contamination, resulting in high-quality end products.

5.2 Aerospace and Automotive Components

The aerospace and automotive industries rely on graphite crucibles for manufacturing components that require precise specifications and high performance. The ability to withstand extreme temperatures and corrosive materials makes graphite crucibles ideal for these applications.

6. How to Choose the Right Graphite Crucible

Selecting the appropriate graphite crucible is critical for the success of your metal casting projects.

6.1 Factors to Consider

Consider the following factors when choosing a graphite crucible:

- **Melting Temperature**: Ensure the crucible can withstand the metals you intend to melt.

- **Size and Capacity**: Choose a size that meets your production needs while ensuring efficient melting.

6.2 Quality Standards

Investing in high-quality graphite crucibles is essential. Look for manufacturers that adhere to industry standards and provide certifications that guarantee the purity and performance of their products.

7. Maintenance and Care for Graphite Crucibles

Proper maintenance can extend the life of graphite crucibles and improve their performance in metal casting processes.

7.1 Cleaning Procedures

After use, it’s crucial to clean graphite crucibles thoroughly. Use a soft brush and mild cleaning solutions to remove any residual materials. Avoid harsh chemicals that could damage the crucible's surface.

7.2 Storage Tips

Store graphite crucibles in a dry and temperature-controlled environment to prevent moisture absorption and potential damage. Additionally, avoid stacking crucibles directly on top of each other to minimize the risk of cracking.

8. Frequently Asked Questions (FAQs)

1. What is the lifespan of a graphite crucible?

The lifespan of a graphite crucible depends on its quality and usage conditions. Generally, they can last from several melts to many hundreds of melts if maintained properly.

2. Can graphite crucibles be reused?

Yes, graphite crucibles can be reused; however, their lifespan depends on the materials used and the melting conditions.

3. What temperatures can graphite crucibles withstand?

Graphite crucibles can typically withstand temperatures exceeding 3000°F (1640°C), making them suitable for a wide variety of metals.

4. Are there any disadvantages to using graphite crucibles?

While graphite crucibles offer many advantages, they can be relatively more expensive than other materials and require careful handling to avoid breakage.

5. How do I know if a graphite crucible is of high quality?

High-quality graphite crucibles should have low porosity, high purity levels, and performance certifications from reputable manufacturers.

9. Conclusion

Graphite crucibles are indispensable tools in the metal casting industry, renowned for their durability, thermal efficiency, and versatility. Understanding their properties and applications enables professionals to make informed decisions, optimizing metal casting processes. By selecting the right graphite crucible and maintaining it properly, manufacturers can ensure high-quality results in their casting endeavors. Embracing the advantages of graphite crucibles ultimately leads to improved production efficiency and superior finished products.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property