Effective Strategies for Maintaining Graphite Electrode Connectors: Ensuring Longevity and Performance

Summary:

Effective Strategies for Maintaining Graphite Electrode Connectors

Graphite electrode connectors play a pivotal role in various industrial applications, particularly in the electrical and manufacturing sectors. Their reliable performance is critical for ensuring optimal system functionality. However, like any other component, these connectors require regular maintenance to maximize their lifespan

Effective Strategies for Maintaining Graphite Electrode Connectors

Graphite electrode connectors play a pivotal role in various industrial applications, particularly in the electrical and manufacturing sectors. Their reliable performance is critical for ensuring optimal system functionality. However, like any other component, these connectors require regular maintenance to maximize their lifespan and efficiency. In this article, we will explore effective strategies for maintaining graphite electrode connectors, providing you with actionable insights that can significantly enhance their performance and durability.

Table of Contents

1. Introduction to Graphite Electrode Connectors

2. The Importance of Maintaining Graphite Electrode Connectors

3. Common Issues with Graphite Electrode Connectors

4. Effective Maintenance Strategies for Graphite Electrode Connectors

- 4.1 Regular Inspection Protocols

- 4.2 Effective Cleaning Techniques

- 4.3 Preventive Measures for Longevity

5. Troubleshooting Tips for Graphite Electrode Connectors

6. Best Practices for Handling and Storing Connectors

7. Frequently Asked Questions

8. Conclusion

Introduction to Graphite Electrode Connectors

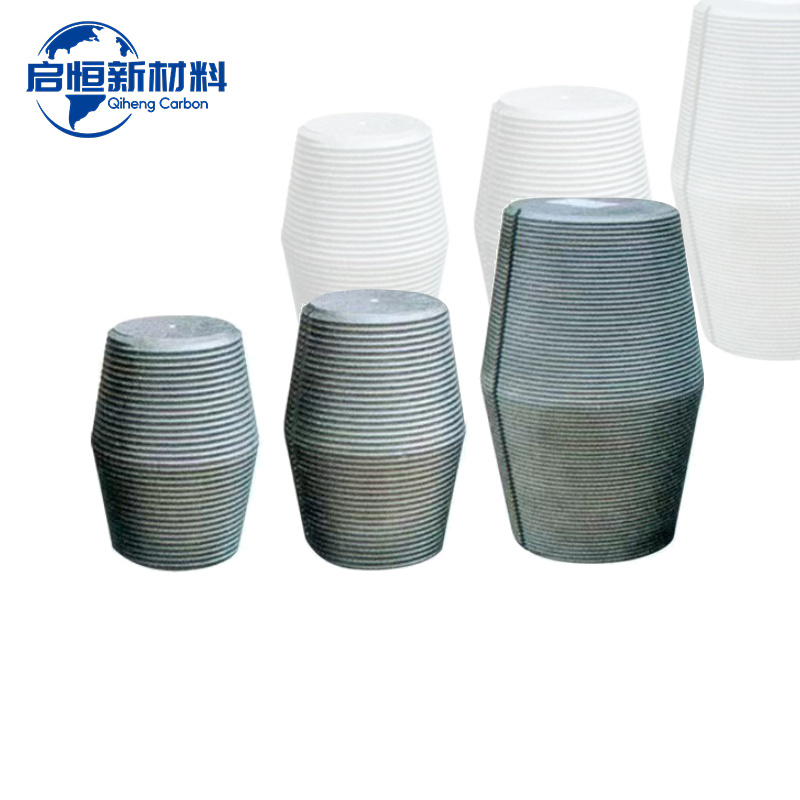

Graphite electrode connectors are essential components used in various electrical applications, particularly in industries such as steel manufacturing, electric arc furnaces, and other high-temperature environments. These connectors facilitate the transfer of electrical current, enabling efficient operation and energy consumption. Understanding the structure and functionality of graphite electrode connectors is key to implementing effective maintenance strategies.

The Importance of Maintaining Graphite Electrode Connectors

Proper maintenance of graphite electrode connectors is critical for several reasons. **First**, regular upkeep reduces the risk of electrical failures, which can lead to costly downtime and repairs. **Second**, well-maintained connectors ensure optimal electrical conductivity, improving the overall efficiency of the equipment. **Finally**, routine maintenance can significantly extend the lifespan of these connectors, providing better return on investment for the business.

Common Issues with Graphite Electrode Connectors

Understanding potential issues that can arise with graphite electrode connectors is essential for effective maintenance. Some of the most common problems include:

- **Wear and Tear**: Continuous use can lead to physical degradation, affecting the connector's performance.

- **Oxidation**: Exposure to high temperatures can cause oxidation, leading to increased resistance and decreased conductivity.

- **Contamination**: Dust, debris, and other pollutants can accumulate on connectors, hindering electrical flow and causing overheating.

- **Mechanical Damage**: Improper handling can result in chipping or cracking, affecting the integrity of the connector.

By being aware of these issues, maintenance professionals can proactively address potential problems before they escalate.

Effective Maintenance Strategies for Graphite Electrode Connectors

Implementing effective maintenance strategies is crucial for ensuring the longevity and performance of graphite electrode connectors. Below, we outline several key strategies that can be undertaken.

Regular Inspection Protocols

Conducting regular inspections is the first step in effective maintenance. Here are some crucial aspects to consider:

- **Visual Checks**: Inspect connectors for any visible signs of wear, damage, or corrosion. Look for cracks, chips, or oxidation.

- **Electrical Testing**: Utilize testing equipment to measure electrical resistance and ensure that connectors are functioning optimally.

- **Thermal Imaging**: Employ thermal imaging technology to identify hotspots which may indicate electrical inefficiencies or impending failures.

Regular inspections should be scheduled based on usage frequency and environmental conditions. Maintaining a log of inspection results can also aid in identifying trends over time.

Effective Cleaning Techniques

Keeping graphite electrode connectors clean is vital for maintaining their performance. Here are some effective cleaning techniques:

- **Dry Cleaning**: Use a soft brush or cloth to remove dust and debris without damaging the surface.

- **Solvent Cleaning**: For more stubborn contaminants, a solvent specifically designed for electrical components can be used. Ensure that the solvent is compatible with graphite.

- **Ultrasonic Cleaning**: For intricate and heavily contaminated connectors, ultrasonic cleaning can provide thorough cleaning without physical abrasion.

After cleaning, allow the connectors to dry completely before reinstallation to prevent moisture-related issues.

Preventive Measures for Longevity

In addition to routine maintenance tasks, implementing preventive measures can significantly extend the lifespan of graphite electrode connectors. Consider the following:

- **Environmental Considerations**: Ensure that connectors are protected from extreme temperatures, humidity, and corrosive substances.

- **Proper Storage**: Store connectors in a clean, dry environment, away from direct sunlight and potential contaminants.

- **Usage Guidelines**: Follow manufacturer guidelines for installation and operation to minimize stress on the connectors.

These preventive measures can create an optimal environment for connectors, reducing the likelihood of premature failure.

Troubleshooting Tips for Graphite Electrode Connectors

Even with regular maintenance, issues can still arise. Here are some troubleshooting tips to resolve common problems:

- **Electrical Resistance Issues**: If you notice increased resistance, check for oxidation and clean the connectors accordingly. If issues persist, consider replacing the connectors.

- **Overheating**: Monitor the operating temperature of connectors. If overheating occurs, inspect for contamination, improper installation, or excessive current loads.

- **Physical Damage**: If connectors are damaged, assess whether repair or replacement is more cost-effective based on the extent of the damage.

Having a systematic approach to troubleshooting can save time and resources while ensuring continued operational efficiency.

Best Practices for Handling and Storing Connectors

In addition to maintenance and troubleshooting, adopting best practices for handling and storing graphite electrode connectors is essential. Follow these best practices:

- **Gentle Handling**: Always handle connectors with care to prevent mechanical damage. Use appropriate tools during installation and removal to minimize stress.

- **Labeling**: Clearly label connectors with relevant information, such as installation dates and inspection results, to facilitate future maintenance.

- **Transport Protocols**: When transporting connectors, use protective packaging to prevent physical damage and exposure to contaminants.

Implementing these best practices not only protects the connectors but also enhances safety during operation and maintenance.

Frequently Asked Questions

1. How often should I inspect graphite electrode connectors?

Regular inspections are recommended every 3-6 months, depending on usage and environmental factors.

2. What cleaning methods are safe for graphite electrode connectors?

Dry cleaning and solvent cleaning with compatible products are safe methods. Ultrasonic cleaning is also effective for heavily contaminated connectors.

3. Can I repair damaged connectors?

Minor damage can sometimes be repaired, but in cases of significant structural integrity loss, replacement is often the better option.

4. What are the signs that a connector needs replacement?

Signs include visible physical damage, excessive oxidation, and increased electrical resistance beyond acceptable limits.

5. Are there specific storage conditions for graphite electrode connectors?

Yes, store them in a clean, dry environment, away from contaminants and extreme temperatures for optimal longevity.

Conclusion

Maintaining graphite electrode connectors is vital for ensuring their longevity and performance in various industrial applications. By implementing **regular inspections**, **effective cleaning techniques**, and **preventive measures**, you can significantly reduce the risk of failures and enhance operational efficiency. Additionally, adopting best practices for handling and storage will further contribute to the reliability of these essential components. By investing time and resources into proper maintenance, you are not only ensuring the longevity of your equipment but also maximizing your return on investment.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property