The Versatile Applications and Benefits of Graphite Powder in Metallurgy and Non-Metallic Mineral Products

Summary:

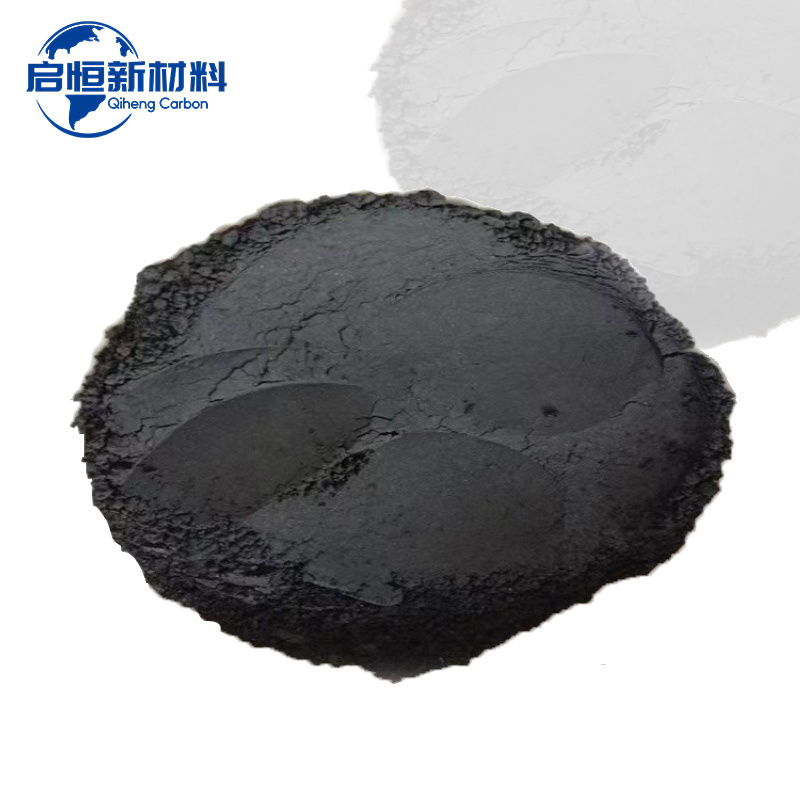

Graphite powder, a form of carbon, is a crucial material in various industrial applications, especially in metallurgy and non-metallic mineral products. Its unique properties, such as high thermal conductivity, chemical inertness, and lubricating characteristics, make it indispensable in several processes.

One of the primary uses of graphite powder in metallurgy is as a lubricant in the production

Graphite powder, a form of carbon, is a crucial material in various industrial applications, especially in metallurgy and non-metallic mineral products. Its unique properties, such as high thermal conductivity, chemical inertness, and lubricating characteristics, make it indispensable in several processes.

One of the primary uses of graphite powder in metallurgy is as a lubricant in the production of metals. The high-temperature stability of graphite allows it to function effectively in environments where other lubricants may fail. This is particularly important in processes such as forging and casting, where metal components are subjected to extreme conditions.

Moreover, graphite powder is widely utilized as a component in refractory materials. These materials must endure high temperatures and harsh environments, making graphite an ideal choice due to its ability to withstand thermal shock and resist oxidation. The incorporation of graphite powder enhances the durability and performance of refractory bricks and castables, contributing to more efficient metal production.

In non-metallic mineral products, graphite powder serves a variety of functions. It is commonly used as a filler in plastics, rubber, and coatings, contributing to improved mechanical properties and thermal conductivity. Its ability to enhance electrical conductivity also makes it a valuable additive in batteries and electronic components. The demand for lightweight and durable materials in these industries has led to an increased interest in graphite powder as a sustainable and efficient solution.

Another significant application of graphite powder is in the production of brake linings and other friction materials. Its natural lubricating properties help reduce wear and tear, leading to improved performance and longevity of automotive components. This makes graphite powder a preferred choice for manufacturers aiming to produce high-quality friction products.

In the energy sector, graphite powder's ability to withstand high temperatures and its chemical stability make it an excellent candidate for use in fuel cells and other energy conversion technologies. As the world shifts towards more sustainable energy solutions, graphite powder is becoming increasingly relevant in the development of advanced energy systems.

In summary, graphite powder is a versatile material with a wide range of applications across metallurgy and non-metallic mineral products. Its unique properties make it an essential ingredient in various industrial processes, contributing to improved performance, efficiency, and sustainability. As industries continue to evolve, the importance of graphite powder will likely grow, driving innovation and enhancing product quality. Understanding its capabilities and applications can provide a significant advantage for professionals in these sectors.

One of the primary uses of graphite powder in metallurgy is as a lubricant in the production of metals. The high-temperature stability of graphite allows it to function effectively in environments where other lubricants may fail. This is particularly important in processes such as forging and casting, where metal components are subjected to extreme conditions.

Moreover, graphite powder is widely utilized as a component in refractory materials. These materials must endure high temperatures and harsh environments, making graphite an ideal choice due to its ability to withstand thermal shock and resist oxidation. The incorporation of graphite powder enhances the durability and performance of refractory bricks and castables, contributing to more efficient metal production.

In non-metallic mineral products, graphite powder serves a variety of functions. It is commonly used as a filler in plastics, rubber, and coatings, contributing to improved mechanical properties and thermal conductivity. Its ability to enhance electrical conductivity also makes it a valuable additive in batteries and electronic components. The demand for lightweight and durable materials in these industries has led to an increased interest in graphite powder as a sustainable and efficient solution.

Another significant application of graphite powder is in the production of brake linings and other friction materials. Its natural lubricating properties help reduce wear and tear, leading to improved performance and longevity of automotive components. This makes graphite powder a preferred choice for manufacturers aiming to produce high-quality friction products.

In the energy sector, graphite powder's ability to withstand high temperatures and its chemical stability make it an excellent candidate for use in fuel cells and other energy conversion technologies. As the world shifts towards more sustainable energy solutions, graphite powder is becoming increasingly relevant in the development of advanced energy systems.

In summary, graphite powder is a versatile material with a wide range of applications across metallurgy and non-metallic mineral products. Its unique properties make it an essential ingredient in various industrial processes, contributing to improved performance, efficiency, and sustainability. As industries continue to evolve, the importance of graphite powder will likely grow, driving innovation and enhancing product quality. Understanding its capabilities and applications can provide a significant advantage for professionals in these sectors.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property