Innovations in Graphite Square Technologies for the Mining Industry

Summary:

Innovations in Graphite Square Technologies for the Mining Industry

Table of Contents

1. Introduction

2. Understanding Graphite Square Technologies

3. Evolution of Graphite Applications in Mining

4. Latest Innovations in Graphite Squares

4.1 Smart Graphite Squares

4.2 Sustainable Production Methods

4.3 Advanced Proce

Innovations in Graphite Square Technologies for the Mining Industry

Table of Contents

- 1. Introduction

- 2. Understanding Graphite Square Technologies

- 3. Evolution of Graphite Applications in Mining

- 4. Latest Innovations in Graphite Squares

- 5. Benefits of Graphite Square Innovations

- 6. Challenges in Graphite Technology Adoption

- 7. Future of Graphite Squares in Mining

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction

The mining industry is undergoing a significant transformation, driven by advancements in technology and the increasing demand for efficient and sustainable solutions. Among these innovations, **graphite square technologies** have emerged as a pivotal element in enhancing productivity and sustainability. As we explore the latest developments in this field, it becomes apparent that the integration of **graphite solutions** into mining operations is not merely an option but a necessity for the industry to thrive in an increasingly competitive environment.

2. Understanding Graphite Square Technologies

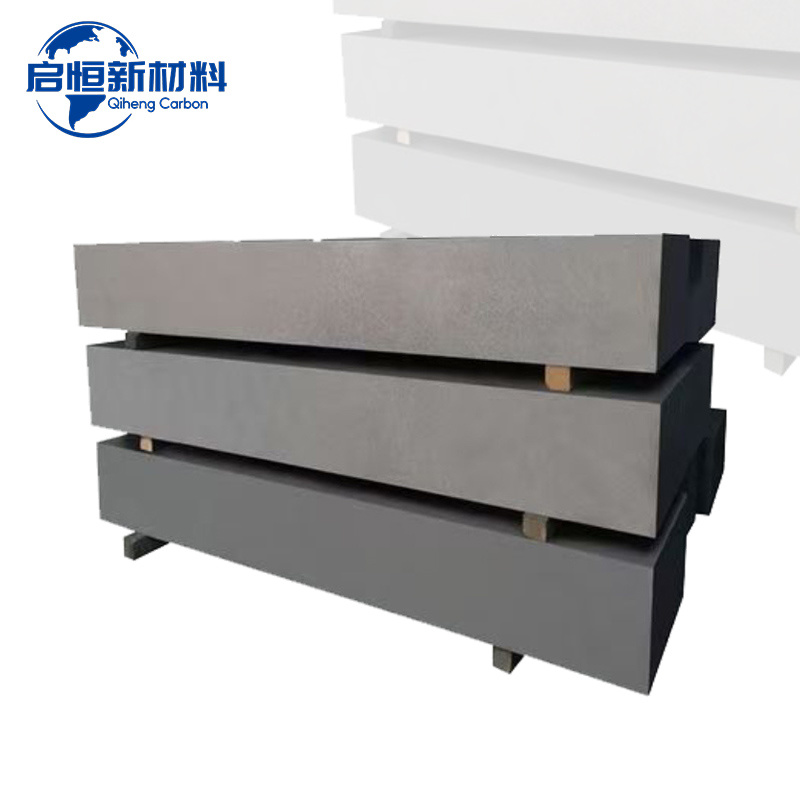

Graphite square technologies refer to the various applications and implementations of graphite materials in the mining sector, particularly focusing on square forms of graphite that maximize utility and functional performance. These technologies leverage the unique properties of graphite, such as its high electrical conductivity, thermal resistance, and mechanical strength, making them ideal for a range of mining applications.

The versatility of graphite enables it to be used in various forms, including **graphite electrodes**, **shaping tools**, and **functional coatings**. The introduction of square forms enhances the ability to mold and utilize graphite in ways that traditional forms do not allow, leading to innovations that can significantly impact production efficiency and operational effectiveness.

3. Evolution of Graphite Applications in Mining

Historically, graphite has been utilized in mining for its lubricating properties and its ability to withstand high temperatures. As the industry evolved, so did the applications of graphite. The introduction of **graphite squares** has revolutionized the way graphite is used within mining operations.

In the early days, graphite was primarily utilized in the production of **pencil leads** and **lubricants**. However, with advancements in technology and an increased understanding of graphite's properties, its applications have expanded to include areas such as **battery technology**, **thermal management systems**, and **reinforcement materials** for composites.

This evolution has not only improved the efficiency of mining operations but has also opened new avenues for innovation in material science, leading to the development of specialized graphite products tailored to meet the specific needs of the mining industry.

4. Latest Innovations in Graphite Squares

As the mining industry continues to innovate, several key advancements in graphite square technologies stand out. These innovations are transforming operational processes and enhancing the performance of mining equipment.

4.1 Smart Graphite Squares

One of the most exciting developments in graphite square technologies is the advent of **smart graphite squares**. These incorporate embedded sensors to monitor performance metrics such as temperature, pressure, and wear levels in real-time. By providing critical data directly to operators, smart graphite squares enable predictive maintenance, minimizing downtime and optimizing performance.

This technology not only helps in prolonging the life of mining equipment but also contributes to reducing operational costs and improving safety standards in mining operations.

4.2 Sustainable Production Methods

Sustainability is at the forefront of industry innovation, and graphite square technologies are no exception. New methods of production are being explored to reduce environmental impact. Techniques such as **solvent-free processing** and the use of **recycled graphite materials** are gaining traction.

These sustainable practices not only help in conserving natural resources but also align with global efforts toward reducing carbon footprints within the mining sector, allowing companies to meet regulatory requirements and consumer expectations for environmentally responsible practices.

4.3 Advanced Processing Techniques

Advanced processing techniques are enhancing the quality and performance of graphite squares. Innovations in **micronization** and **sintering processes** are allowing for the production of high-purity graphite squares that exhibit superior mechanical properties and thermal stability.

Such advancements enable the use of graphite in more demanding applications, such as in high-performance batteries and advanced thermal management systems, which are increasingly important in modern mining operations.

5. Benefits of Graphite Square Innovations

The innovations in graphite square technologies present numerous benefits for the mining industry. These advantages include:

- **Enhanced Efficiency**: The incorporation of smart technologies and advanced processing leads to improved operational efficiencies, reducing costs and increasing output.

- **Sustainability**: Sustainable production practices contribute to reduced environmental impact, aligning with the global push for greener mining solutions.

- **Improved Safety**: Smart graphite squares enable better monitoring of equipment conditions, minimizing operational hazards and enhancing worker safety.

- **Material Versatility**: Advanced graphite materials can be tailored for specific applications, providing solutions that traditional materials cannot offer.

- **Longer Lifespan of Equipment**: The durability and strength of graphite squares prolong the lifespan of mining tools and equipment, resulting in lower replacement costs.

6. Challenges in Graphite Technology Adoption

Despite the significant advancements in graphite square technologies, several challenges exist in their adoption within the mining industry.

- **Cost of Implementation**: The initial investment in new technologies can be substantial, deterring some companies from transitioning to graphite solutions.

- **Knowledge Gap**: There is a need for training and education in the benefits and applications of graphite technologies, as many mining professionals may not be familiar with these advancements.

- **Regulatory Hurdles**: Compliance with environmental and safety regulations can pose challenges for the adoption of new materials and technologies in mining operations.

7. Future of Graphite Squares in Mining

The future of graphite square technologies in the mining industry appears promising. As research and development continue to evolve, we anticipate significant breakthroughs in not just material science but also in the application of these technologies across various mining sectors.

- **Increased Automation**: The integration of artificial intelligence with smart graphite technologies will likely lead to enhanced automation in mining operations, improving decision-making processes and operational efficiency.

- **Broader Applications**: As more industries recognize the benefits of graphite, we can expect to see increased demand across various applications, including electronics, renewable energy, and automotive sectors, further driving innovation within mining.

- **Collaborative Innovations**: Partnerships between academic institutions, technology companies, and mining firms are expected to yield innovative solutions that address current challenges and enhance the functionality of graphite square technologies.

8. Frequently Asked Questions

What are graphite squares used for in the mining industry?

Graphite squares are utilized in various applications, including lubrication, thermal management, and as conductive materials in mining equipment.

How do smart graphite squares improve mining operations?

Smart graphite squares provide real-time monitoring capabilities, enabling predictive maintenance and reducing downtime, leading to increased operational efficiency.

What sustainable practices are associated with graphite production?

Sustainable practices include solvent-free processing, recycling of graphite materials, and reducing the carbon footprint associated with mining operations.

What challenges do mining companies face in adopting graphite technologies?

Challenges include high implementation costs, a knowledge gap regarding new technologies, and navigating regulatory requirements.

What is the future outlook for graphite square technologies in mining?

The future includes advancements in automation, broader applications across industries, and collaborative innovation partnerships that enhance graphite technologies.

9. Conclusion

The **innovations in graphite square technologies** are reshaping the landscape of the mining industry. With their ability to enhance efficiency, promote sustainability, and improve safety, these advancements are not merely trends but essential components of modern mining practices. As the industry continues to evolve, embracing these innovations will be critical for companies aiming to remain competitive and responsive to the challenges of a rapidly changing global market. The future of mining is undeniably intertwined with the advancements in graphite technologies, paving the way for a more efficient and sustainable industry.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property