Graphite Crucibles: A Detailed Comparison Between Natural and Synthetic Graphite

Summary:

Graphite Crucibles: A Comprehensive Comparison of Natural vs. Synthetic Graphite

Table of Contents

1. Introduction to Graphite Crucibles

2. What is Graphite?

3. Types of Graphite: Natural vs. Synthetic

4. Properties of Natural Graphite

5. Properties of Synthetic Graphite

6. Applications of Graphite Crucibles in Industry

7. Advantages of Natural Graphite Crucibles

Graphite Crucibles: A Comprehensive Comparison of Natural vs. Synthetic Graphite

Table of Contents

- 1. Introduction to Graphite Crucibles

- 2. What is Graphite?

- 3. Types of Graphite: Natural vs. Synthetic

- 4. Properties of Natural Graphite

- 5. Properties of Synthetic Graphite

- 6. Applications of Graphite Crucibles in Industry

- 7. Advantages of Natural Graphite Crucibles

- 8. Advantages of Synthetic Graphite Crucibles

- 9. Conclusion

- 10. Frequently Asked Questions (FAQs)

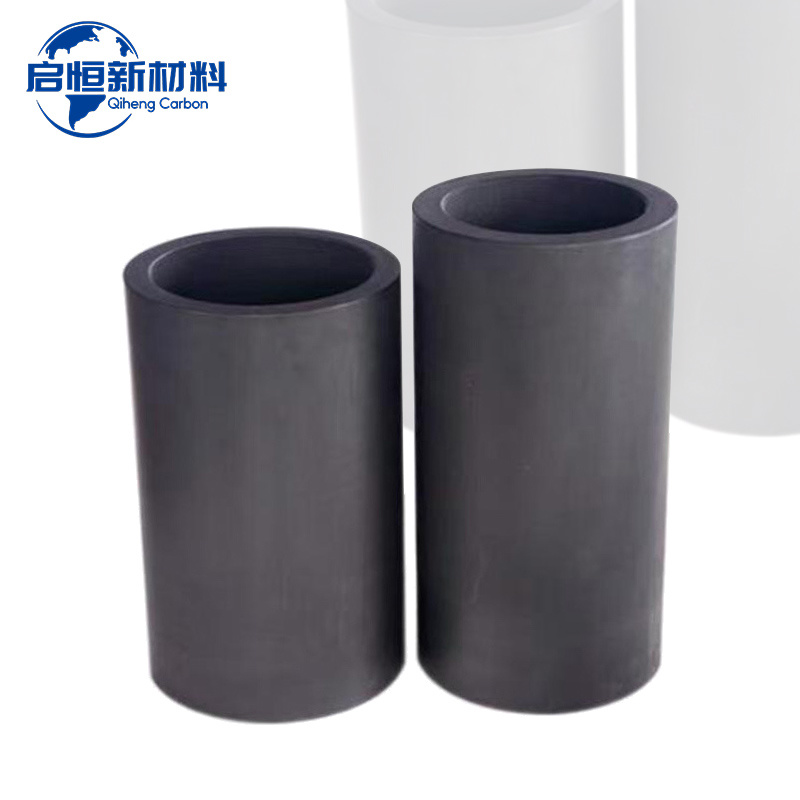

1. Introduction to Graphite Crucibles

Graphite crucibles are essential components used in various industries, particularly in metallurgy and materials science. They serve as containers for melting and refining metals due to their ability to withstand high temperatures and resist chemical reactions. The choice between natural and synthetic graphite crucibles significantly impacts performance, durability, and suitability for specific applications. This article offers a detailed comparison of **natural vs. synthetic graphite** crucibles, examining their properties, applications, and benefits.

2. What is Graphite?

Graphite is a naturally occurring form of carbon, characterized by its layered structure and excellent thermal and electrical conductivity. This unique arrangement of carbon atoms allows graphite to exhibit remarkable properties, making it suitable for various industrial applications. It is primarily used in the production of batteries, lubricants, and, crucially, crucibles for melting metals.

3. Types of Graphite: Natural vs. Synthetic

Graphite can be broadly classified into two categories: **natural graphite** and **synthetic graphite**. Each type has distinct characteristics that influence its performance in crucible applications.

3.1 Natural Graphite

Natural graphite is mined from the earth and can be found in three main forms: flake, amorphous, and lump graphite. The purity and crystallinity of natural graphite vary by source, affecting its thermal and electrical properties.

3.2 Synthetic Graphite

Synthetic graphite is manufactured from carbon-rich materials through high-temperature processes. It is engineered to have specific properties tailored for various applications, providing consistency and predictability in performance.

4. Properties of Natural Graphite

Natural graphite possesses several important properties that make it attractive for use in crucibles:

4.1 High Thermal Conductivity

Natural graphite exhibits excellent thermal conductivity, allowing it to transfer heat efficiently. This property is vital in melting applications where uniform temperature distribution is essential.

4.2 Chemical Resistance

Natural graphite is highly resistant to chemical corrosion, making it suitable for use with various metals and alloys.

4.3 Low Coefficient of Thermal Expansion

The low coefficient of thermal expansion ensures that natural graphite crucibles maintain their shape and integrity under extreme temperature changes.

5. Properties of Synthetic Graphite

Synthetic graphite is engineered to meet specific requirements and thus offers several advantages over its natural counterpart:

5.1 Customizability

Synthetic graphite can be produced to specific standards, allowing for modification in terms of porosity, density, and thermal conductivity. This customizability makes it suitable for specialized applications.

5.2 Higher Purity Levels

The manufacturing process of synthetic graphite allows for higher purity levels, minimizing the risk of contamination during melting processes.

5.3 Enhanced Mechanical Strength

Synthetic graphite often exhibits superior mechanical strength compared to natural graphite, providing better resistance to cracking and deformation under stress.

6. Applications of Graphite Crucibles in Industry

Both natural and synthetic graphite crucibles are widely used in various industries, including metallurgy, electronics, and ceramics. They are particularly favored in applications where high temperatures and chemical reactions occur.

6.1 Metallurgy

In metallurgy, graphite crucibles are crucial for melting and refining metals. They are particularly effective for non-ferrous metals such as aluminum, copper, and gold, where purity is paramount.

6.2 Electronics

Graphite crucibles play a vital role in the production of semiconductor materials and other electronic components, where precision and thermal stability are essential.

6.3 Ceramics

In the ceramics industry, graphite crucibles are used to melt and mold ceramic materials, benefiting from their ability to withstand high temperatures without deforming.

7. Advantages of Natural Graphite Crucibles

Natural graphite crucibles offer several benefits that can be advantageous in certain applications:

7.1 Cost-Effectiveness

Natural graphite is generally more cost-effective than synthetic alternatives, making it an attractive option for businesses looking to reduce expenses.

7.2 Eco-Friendly Option

Being a naturally occurring material, natural graphite has a smaller carbon footprint compared to synthetic graphite, which requires energy-intensive manufacturing processes.

7.3 Proven Performance

Natural graphite has been trusted for centuries in various applications, demonstrating reliable performance across diverse industries.

8. Advantages of Synthetic Graphite Crucibles

Synthetic graphite crucibles also have distinct advantages that may make them preferable in specific circumstances:

8.1 Consistent Quality

Synthetic graphite's manufacturing process ensures uniformity in quality, minimizing variations that could affect performance.

8.2 Tailored Performance

The ability to customize synthetic graphite allows for adjustments to meet specific operational requirements, offering enhanced efficiency and effectiveness.

8.3 Lower Impurities

With higher purity levels, synthetic graphite significantly reduces the risk of contamination in sensitive applications such as electronics and high-precision metallurgy.

9. Conclusion

In the debate between natural and synthetic graphite crucibles, both options present unique advantages and limitations. **Natural graphite** is often favored for its cost-effectiveness and eco-friendliness, while **synthetic graphite** stands out for its customizable properties and consistent quality. The choice ultimately depends on the specific requirements of the application, including the desired purity, thermal properties, and the type of material being processed. A thorough understanding of the differences can help businesses make informed decisions that enhance efficiency and performance in their operations.

10. Frequently Asked Questions (FAQs)

10.1 What are graphite crucibles used for?

Graphite crucibles are primarily used for melting metals and alloys in various industries, including metallurgy, electronics, and ceramics.

10.2 How do natural and synthetic graphite crucibles differ in performance?

Natural graphite crucibles are more cost-effective and eco-friendly, while synthetic graphite crucibles offer higher purity, better mechanical strength, and customizability.

10.3 Can graphite crucibles be reused?

Yes, graphite crucibles can be reused multiple times, depending on their condition and the type of materials being melted.

10.4 What temperatures can graphite crucibles withstand?

Graphite crucibles can typically withstand temperatures up to 3000°C (5432°F) depending on the specific type and manufacturing quality.

10.5 Are there any safety concerns with using graphite crucibles?

While graphite crucibles are generally safe to use, precautions should be taken to handle them properly when working with high temperatures and molten materials to prevent burns or other injuries.

This comprehensive article on **Graphite Crucibles: A Comparison of Natural vs. Synthetic Graphite** provides an in-depth analysis to help readers understand the distinct properties and advantages of both types of graphite crucibles. By utilizing this information, businesses can make informed decisions tailored to their specific needs.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property