Exploring the Benefits of Graphite Electrode Connectors in High-Voltage Applications

Summary:

Exploring the Benefits of Graphite Electrode Connectors in High-Voltage Applications

Table of Contents

1. Introduction to Graphite Electrode Connectors

2. What Are Graphite Electrode Connectors?

3. Advantages of Graphite Electrode Connectors in High-Voltage Applications

4. Key Applications of Graphite Electrode Connectors

5. Performance Attributes That Enhance Reliability

Exploring the Benefits of Graphite Electrode Connectors in High-Voltage Applications

Table of Contents

- 1. Introduction to Graphite Electrode Connectors

- 2. What Are Graphite Electrode Connectors?

- 3. Advantages of Graphite Electrode Connectors in High-Voltage Applications

- 4. Key Applications of Graphite Electrode Connectors

- 5. Performance Attributes That Enhance Reliability

- 6. Maintenance Considerations for Graphite Connectors

- 7. Comparative Analysis: Graphite vs. Traditional Connectors

- 8. Future Trends in Graphite Electrode Connector Technology

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Graphite Electrode Connectors

In the realm of high-voltage electrical applications, the significance of reliable connections cannot be overstated. **Graphite electrode connectors** have emerged as a superior choice, offering unique properties that cater to the demanding requirements of high-voltage systems. This article will delve deep into the various benefits, applications, and future trends of these innovative connectors.

2. What Are Graphite Electrode Connectors?

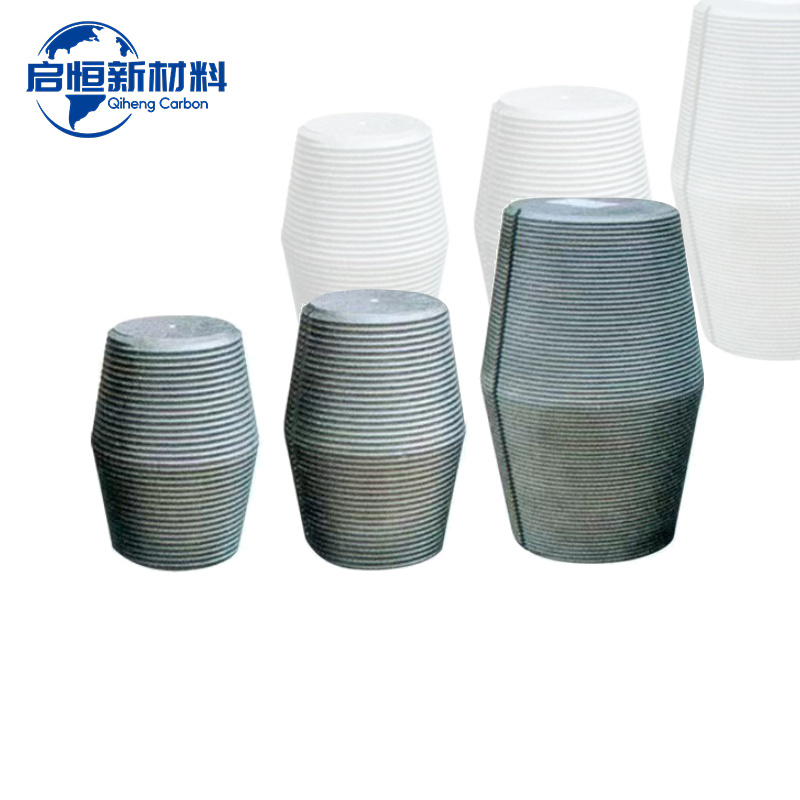

Graphite electrode connectors are specialized components designed to facilitate electrical connections in environments where high voltage and current are prevalent. Composed primarily of high-quality graphite, these connectors exhibit excellent conductivity and thermal stability. Their unique composition allows them to withstand harsh operational conditions, making them ideal for a wide range of applications, including power generation, transmission, and industrial machinery.

3. Advantages of Graphite Electrode Connectors in High-Voltage Applications

The adoption of graphite electrode connectors in high-voltage applications brings forth numerous advantages that enhance the overall performance and longevity of electrical systems.

3.1 Exceptional Electrical Conductivity

One of the primary benefits of graphite connectors is their **superior electrical conductivity**. Graphite maintains low resistance, enabling efficient current flow and minimizing energy loss. This property is crucial in high-voltage applications where even minute resistance can lead to significant power losses.

3.2 Thermal Stability and Resistance to Heat

Graphite can withstand elevated temperatures without deteriorating. This thermal stability ensures that connectors maintain their integrity and performance even under extreme conditions, making them highly suitable for high-voltage systems that generate substantial heat.

3.3 Corrosion Resistance

Unlike traditional metal connectors, graphite is inherently resistant to corrosion. This characteristic allows graphite electrode connectors to function effectively in harsh environments, extending their service life and reducing maintenance costs.

3.4 Lightweight and Easy to Handle

Graphite connectors are lightweight compared to their metal counterparts, making them easier to handle and install. This feature not only reduces labor costs but also enhances the efficiency of installation processes in various high-voltage settings.

3.5 Versatility in Application

Due to their unique properties, graphite electrode connectors are versatile and can be customized for different applications. Whether used in electrical power systems, rail transport, or industrial machinery, these connectors can be tailored to meet specific requirements and conditions.

4. Key Applications of Graphite Electrode Connectors

Graphite electrode connectors find applications across various industries due to their exceptional performance characteristics. Here are some of the key applications:

4.1 Power Generation and Distribution

In power generation and distribution systems, maintaining reliable electrical connections is critical. Graphite connectors are commonly used in substations, transformers, and switchgear, ensuring efficient and safe operation.

4.2 Rail Transport Systems

The rail transport industry relies on high-voltage systems for powering locomotives and other equipment. Graphite electrode connectors provide robust connections that ensure the reliability and efficiency of electrical systems in this sector.

4.3 Industrial Machinery

Heavy machinery in industrial settings often requires high-voltage connections. Graphite connectors are ideal for these applications, offering durability and performance that withstands the rigors of industrial use.

4.4 Renewable Energy Solutions

As the world shifts towards renewable energy sources, the demand for reliable electrical connections in solar and wind energy systems increases. Graphite electrode connectors are increasingly being adopted in these applications, providing efficiency and longevity.

5. Performance Attributes That Enhance Reliability

The reliability of graphite electrode connectors in high-voltage applications is attributed to various performance attributes that set them apart from traditional connectors.

5.1 Low Contact Resistance

Graphite connectors exhibit low contact resistance, which minimizes voltage drop and energy loss. This attribute ensures that systems operate at optimal efficiency and contributes to the overall longevity of the equipment.

5.2 High Arc Resistance

Graphite materials possess high arc resistance, making them safer in high-voltage applications. This quality reduces the risk of arcing, which can lead to connector failure or damage to surrounding equipment.

5.3 Enhanced Mechanical Strength

Graphite electrode connectors are designed to withstand mechanical stress and vibration. This robustness is essential in high-voltage applications where equipment is often subject to dynamic forces.

6. Maintenance Considerations for Graphite Connectors

Proper maintenance of graphite electrode connectors is crucial to ensure their optimal performance and longevity.

6.1 Regular Inspections

Frequent inspections should be conducted to check for any signs of wear, degradation, or damage. Regular monitoring allows for early detection of potential issues, enabling timely maintenance or replacement.

6.2 Cleaning Practices

While graphite connectors are resistant to corrosion, they can accumulate dirt and debris over time. Regular cleaning is essential to maintain conductivity and performance. Use appropriate cleaning agents that do not damage the graphite material.

6.3 Replacement Awareness

Although graphite connectors are durable, they may require replacement after extended use. Awareness of their operational lifespan helps in planning maintenance schedules and ensuring system reliability.

7. Comparative Analysis: Graphite vs. Traditional Connectors

When assessing the benefits of graphite electrode connectors, it is essential to compare them with traditional metal connectors.

7.1 Conductivity Comparison

While traditional copper and aluminum connectors offer good conductivity, graphite connectors often outperform them in specific applications, especially under extreme conditions.

7.2 Cost Considerations

Although graphite connectors may have a higher initial cost, their longevity and reduced maintenance needs often lead to overall cost savings in the long term.

7.3 Weight and Handling

Graphite connectors are generally lighter than metal connectors, making them easier to handle and reducing installation costs, a significant advantage in high-voltage applications.

8. Future Trends in Graphite Electrode Connector Technology

As technology evolves, so do the applications and designs of graphite electrode connectors. Here are some trends to watch for in the future:

8.1 Advanced Material Science

Research in material science continues to enhance the properties of graphite connectors, aiming for improved performance and efficiency in high-voltage applications.

8.2 Integration with Smart Technology

The future may see the integration of smart technology within graphite connectors, allowing for real-time monitoring of performance and diagnostics, thereby improving reliability and maintenance strategies.

8.3 Sustainable Practices

As industries move towards sustainability, the development of eco-friendly manufacturing processes for graphite connectors will gain prominence, aligning with global environmental goals.

9. Frequently Asked Questions

9.1 What makes graphite electrode connectors better than copper connectors?

Graphite connectors offer superior thermal stability, corrosion resistance, and lower weight compared to copper connectors, making them ideal for high-voltage applications.

9.2 Can graphite electrode connectors be used in outdoor environments?

Yes, graphite connectors are resistant to environmental factors such as moisture and corrosion, making them suitable for outdoor applications.

9.3 How do I maintain graphite electrode connectors?

Regular inspections, cleaning, and awareness of their operational lifespan are essential for maintaining the performance of graphite electrode connectors.

9.4 Are graphite electrode connectors cost-effective?

While the initial cost may be higher, their durability and low maintenance needs often result in long-term cost savings.

9.5 What future advancements can we expect in graphite connector technology?

Expect advancements in material science, integration with smart technology for monitoring, and more sustainable manufacturing practices.

10. Conclusion

Graphite electrode connectors present a robust and efficient solution for high-voltage applications, offering a range of benefits that enhance performance and reliability. Their exceptional electrical conductivity, thermal stability, and corrosion resistance position them as a superior choice over traditional connectors. As industries continue to embrace advanced technologies and sustainable practices, the role of graphite electrode connectors will likely expand, paving the way for innovations in electrical systems. Investing in these connectors not only promises operational efficiency but also contributes to the longevity of high-voltage applications.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property