Graphite Electrodes: Pivotal Components in Enhancing Steel Quality

Summary:

Introduction to Graphite Electrodes in Steel Production

Graphite electrodes play an indispensable role in the production of high-quality steel, serving as a conduit for electrical current in Electric Arc Furnaces (EAF). This article investigates the impact of graphite electrodes on steel quality, examining their properties, manufacturing processes, and the latest advancements in this vital secto

Introduction to Graphite Electrodes in Steel Production

Graphite electrodes play an indispensable role in the production of high-quality steel, serving as a conduit for electrical current in Electric Arc Furnaces (EAF). This article investigates the impact of graphite electrodes on steel quality, examining their properties, manufacturing processes, and the latest advancements in this vital sector.

Understanding Graphite Electrodes

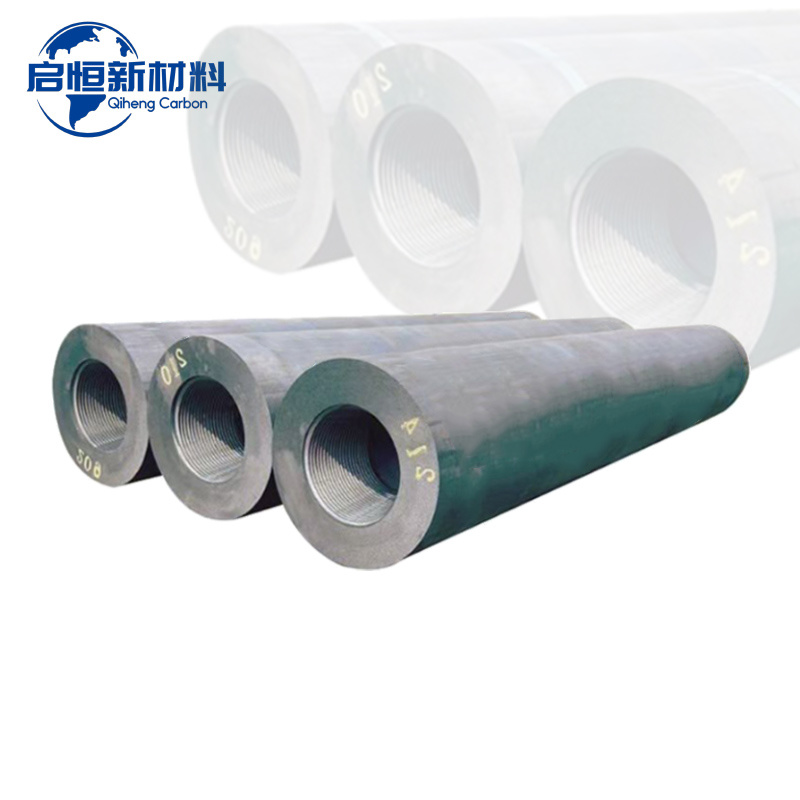

Graphite electrodes are made from high-purity graphite, which possesses excellent electrical conductivity and thermal stability. These electrodes are essential for melting scrap steel and producing new steel products in EAFs. Their unique properties contribute significantly to the efficiency and quality of the steel-making process.

The Composition of Graphite Electrodes

The quality of graphite electrodes is determined by several factors, including the raw materials used, the manufacturing process, and the specific treatments applied. Typically, the production process involves:

- **Petroleum Coke**: A primary raw material that provides the necessary carbon content.

- **Coal Tar Pitch**: Used as a binding agent to hold the coke particles together.

- **Impregnation**: Enhances the density and electrical conductivity of the electrodes.

This intricate composition allows for the creation of electrodes that excel in performance, enabling steel manufacturers to achieve superior results.

Types of Graphite Electrodes

Graphite electrodes come in various types, each tailored for specific applications:

- **Regular Power Graphite Electrodes**: Commonly used in standard steel production.

- **High Power Graphite Electrodes**: Suitable for higher-capacity furnaces, offering enhanced performance.

- **Ultra High Power Graphite Electrodes**: Designed for extreme conditions, delivering exceptional thermal and electrical conductivity.

Understanding these distinctions is crucial for steel manufacturers aiming to enhance their production processes and steel quality.

The Role of Graphite Electrodes in Enhancing Steel Quality

The use of high-quality graphite electrodes directly influences the quality of steel produced. Their properties lead to several advantages in the steel-making process.

Improved Melting Efficiency

Graphite electrodes facilitate a more efficient melting process by providing a consistent electrical current. This efficiency not only reduces energy consumption but also ensures a more uniform temperature within the furnace. Consequently, this leads to a cleaner steel product with fewer impurities.

Reduction of Contaminants

The high purity of graphite electrodes minimizes the introduction of contaminants into the molten steel. By maintaining the integrity of the steel, manufacturers can produce high-grade products that meet industry standards.

Enhanced Mechanical Properties

Steel produced using high-quality graphite electrodes exhibits improved mechanical properties, such as better tensile strength, ductility, and toughness. This enhancement is crucial for applications where steel is subjected to extreme conditions or stress.

Innovations in Graphite Electrode Technology

The graphite electrode industry is witnessing continuous innovation aimed at improving performance and reducing environmental impact.

Advanced Manufacturing Techniques

Innovative manufacturing techniques, such as the use of advanced molding processes and enhanced impregnation methods, have led to the development of high-performance electrodes. These methods increase density and electrical conductivity while reducing production costs.

Recyclability and Sustainability

As the steel industry strives for sustainability, the recyclability of graphite electrodes has gained prominence. Many manufacturers are now focusing on reusing materials, which not only reduces waste but also lowers production costs.

Digital Technology and Automation

The integration of digital technology in the production of graphite electrodes allows manufacturers to monitor quality and performance in real-time. Automated processes enhance precision and reduce human error, contributing to overall efficiency.

Applications of Graphite Electrodes Beyond Steel Production

While primarily used in steel manufacturing, graphite electrodes have applications in other industries, including:

Non-Ferrous Metal Production

Graphite electrodes are also employed in the production of non-ferrous metals like aluminum and copper, where similar melting processes are used.

Foundry Applications

In foundries, graphite electrodes facilitate the melting of various metals, making them integral to the casting process.

Specialty Alloys and Composites

Graphite electrodes are vital in producing specialty alloys and composites that require precise temperature control and high-quality materials.

Challenges Facing the Graphite Electrode Industry

Despite their essential role, the graphite electrode industry faces several challenges that necessitate ongoing innovation and improvement.

Raw Material Supply Issues

The sourcing of high-quality raw materials, particularly petroleum coke, has become increasingly challenging due to market fluctuations. This can impact the production costs and availability of graphite electrodes.

Environmental Regulations

With growing environmental concerns, manufacturers must comply with stringent regulations regarding emissions and waste management. This drives the need for cleaner production technologies and sustainable practices.

Market Competition

As the demand for high-quality steel increases, competition within the graphite electrode market intensifies, pushing manufacturers to innovate continually and improve their offerings.

Future Trends in Graphite Electrodes

The future of graphite electrodes looks promising, with several trends poised to shape their development.

Integration of Nanotechnology

Research into nanotechnology may lead to the creation of advanced materials that enhance the properties of graphite electrodes, resulting in better performance and durability.

Focus on Energy Efficiency

With energy costs rising, there's an increasing emphasis on developing electrodes that optimize energy consumption during steel production, thus reducing operational costs for manufacturers.

Collaboration Across Industries

Collaboration between graphite electrode manufacturers and steel producers can lead to the development of tailored solutions that meet specific production needs, fostering innovation and improving overall efficiency.

Frequently Asked Questions (FAQs)

1. What are graphite electrodes used for in steel production?

Graphite electrodes are primarily used to conduct electricity in electric arc furnaces, facilitating the melting of scrap steel and the production of high-quality steel.

2. How do graphite electrodes enhance steel quality?

They improve melting efficiency, reduce contaminants, and enhance the mechanical properties of the steel produced.

3. What are the different types of graphite electrodes?

The main types include regular power, high power, and ultra-high power graphite electrodes, each suited for different production conditions.

4. Are graphite electrodes recyclable?

Yes, many graphite electrodes can be recycled, contributing to sustainability in the steel production process.

5. What challenges does the graphite electrode industry face?

Challenges include raw material supply issues, strict environmental regulations, and intense market competition.

Conclusion

Graphite electrodes are vital to the steel production process, significantly enhancing the quality of steel through improved melting efficiency, reduced contaminants, and better mechanical properties. As the industry evolves, innovations in technology and sustainability practices will play a crucial role in addressing challenges and meeting the growing demand for high-quality steel. By understanding the importance of graphite electrodes, manufacturers can ensure they remain at the forefront of the steel-making industry, delivering superior products that meet both current and future needs.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property