How UHP Graphite Electrodes are Revolutionizing the Metallurgical Industry

Summary:

How UHP Graphite Electrodes are Revolutionizing the Metallurgical Industry

Table of Contents

1. Introduction to UHP Graphite Electrodes

2. What are UHP Graphite Electrodes?

3. Advantages of UHP Graphite Electrodes in Metallurgy

3.1 Enhanced Thermal Conductivity

3.2 Improved Energy Efficiency

3.3 Longer Service Life

4. Appl

How UHP Graphite Electrodes are Revolutionizing the Metallurgical Industry

Table of Contents

- 1. Introduction to UHP Graphite Electrodes

- 2. What are UHP Graphite Electrodes?

- 3. Advantages of UHP Graphite Electrodes in Metallurgy

- 4. Applications of UHP Graphite Electrodes in Metallurgy

- 5. Sustainability Aspects of UHP Graphite Electrodes

- 6. Future Trends in UHP Graphite Electrodes

- 7. Frequently Asked Questions (FAQs)

- 8. Conclusion

1. Introduction to UHP Graphite Electrodes

The metallurgical industry stands at the frontier of technological innovation, and at its core lies a crucial component: **Ultra High Power (UHP) graphite electrodes**. These electrodes are not merely tools but pivotal elements that enhance efficiency, sustainability, and productivity in various metallurgical processes. This article delves deep into how UHP graphite electrodes are reshaping the industry and why they are essential for modern metallurgical operations.

2. What are UHP Graphite Electrodes?

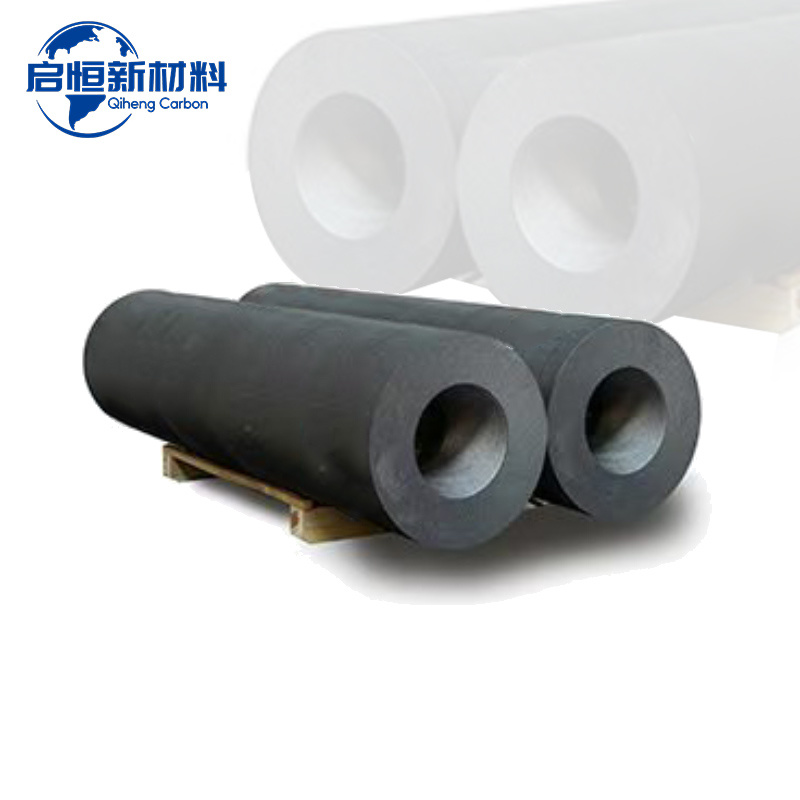

UHP graphite electrodes are specialized electrodes designed for use in high-power applications, particularly in electric arc furnaces (EAFs). Characterized by their superior conductivity and durability, UHP graphite electrodes are essential for melting ferrous and non-ferrous metals. They are composed of high-quality petroleum and pitch coke, which are processed at extremely high temperatures to create a dense and cohesive structure.

The uniqueness of UHP graphite electrodes lies in their ability to withstand extreme temperatures and maintain integrity under significant electrical loads. This capability allows them to be used in various applications requiring high performance and reliability.

3. Advantages of UHP Graphite Electrodes in Metallurgy

UHP graphite electrodes offer numerous advantages that make them indispensable in the metallurgical industry. Let’s explore some of the key benefits.

3.1 Enhanced Thermal Conductivity

One of the standout features of UHP graphite electrodes is their **exceptional thermal conductivity**. This property ensures efficient heat transfer during the melting process, leading to improved energy use and reduced operational costs. Enhanced thermal conductivity allows for quicker melting times and a more uniform temperature distribution within the furnace, facilitating better metal quality.

3.2 Improved Energy Efficiency

Energy consumption is a significant concern in the metallurgical sector. UHP graphite electrodes contribute to **energy efficiency** by minimizing electrical resistance during operation. This reduction in resistance translates into lower energy usage without compromising performance. With energy costs continuously rising, the financial savings achieved through energy-efficient practices can be substantial.

3.3 Longer Service Life

The robust construction of UHP graphite electrodes yields a **longer service life**, reducing the frequency of replacements. This durability is particularly advantageous in industrial settings, where downtime can result in significant losses. With fewer interruptions necessary for electrode replacement, companies can maintain smoother operations and optimize production schedules.

4. Applications of UHP Graphite Electrodes in Metallurgy

UHP graphite electrodes find diverse applications throughout the metallurgical industry. Their versatility ensures they play a significant role in various processes.

4.1 Electric Arc Furnaces

Electric arc furnaces are arguably the most significant application for UHP graphite electrodes. They serve as the primary source of heat to melt scrap steel and other metals. The high efficiency and power capabilities of UHP electrodes make them ideal for this purpose, enabling steelmakers to produce high-quality steel while minimizing environmental impacts.

4.2 Foundries

In foundries, UHP graphite electrodes are used in induction furnaces for melting and alloying metals. The precision and reliability of UHP electrodes ensure that foundries can meet stringent quality requirements while optimizing their processes. The ability to handle high temperatures and resist thermal shock makes them a preferred choice in these settings.

4.3 Ladle Furnaces

Ladle furnaces also benefit from UHP graphite electrodes, particularly for secondary metallurgy processes. These electrodes help maintain the desired temperature and composition of molten metal, providing crucial control over the final product. The reliability of UHP graphite electrodes in ladle furnaces enhances overall productivity and quality assurance in steelmaking.

5. Sustainability Aspects of UHP Graphite Electrodes

Sustainability is a growing concern across all industries, and the metallurgical sector is no exception. UHP graphite electrodes contribute to sustainable practices in several ways:

1. **Reduced Energy Consumption**: The energy efficiency of UHP electrodes leads to lower carbon emissions during production processes.

2. **Recycling**: The use of scrap metal in electric arc furnaces promotes recycling, which conserves natural resources and reduces waste.

3. **Lower Emissions**: Advanced technologies in UHP electrode manufacturing minimize harmful emissions, supporting a cleaner environment.

By embracing UHP graphite electrodes, metallurgical operations can align with global sustainability goals while maintaining competitive advantages.

6. Future Trends in UHP Graphite Electrodes

As the metallurgical industry continues to evolve, several trends are emerging concerning UHP graphite electrodes:

- **Innovation in Materials**: Research is ongoing into developing new materials that enhance the performance and durability of UHP electrodes further.

- **Automation and Smart Technologies**: The integration of smart technologies in electrode production and application can lead to enhanced monitoring and efficiency.

- **Increased Demand for Recycling**: As environmental awareness rises, the demand for recycled metals will drive further advancements in electrode technology to support sustainable practices.

These trends indicate a promising future for UHP graphite electrodes, ultimately leading to advancements in efficiency, sustainability, and quality within the metallurgical industry.

7. Frequently Asked Questions (FAQs)

What are the main benefits of using UHP graphite electrodes?

The main benefits of UHP graphite electrodes include enhanced thermal conductivity, improved energy efficiency, and a longer service life, which collectively contribute to reduced operational costs and increased productivity.

How do UHP graphite electrodes differ from regular graphite electrodes?

UHP graphite electrodes are designed to withstand higher power and temperatures than regular graphite electrodes, making them suitable for high-performance applications such as electric arc furnaces.

Can UHP graphite electrodes be recycled?

Yes, UHP graphite electrodes can be recycled. Their use in electric arc furnaces promotes the recycling of scrap metal, making them an environmentally friendly option.

What industries utilize UHP graphite electrodes?

UHP graphite electrodes are primarily used in the metallurgical industry, particularly in steelmaking, foundries, and other sectors requiring high-temperature melting processes.

How does the use of UHP graphite electrodes contribute to sustainability?

The use of UHP graphite electrodes reduces energy consumption, supports recycling efforts, and minimizes emissions, making them an integral part of sustainable practices in metallurgy.

8. Conclusion

The advent of **Ultra High Power (UHP) graphite electrodes** signifies a monumental shift in the metallurgical industry. By optimizing energy efficiency, enhancing thermal conductivity, and offering a longer service life, these electrodes enable metallurgical operations to achieve unprecedented levels of productivity and sustainability. As the industry evolves, embracing UHP graphite electrodes will become increasingly essential for businesses seeking to remain competitive and environmentally responsible. The future of metallurgy looks promising, and UHP graphite electrodes will undoubtedly play a crucial role in shaping that future.

Previous:

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property