Exploring the Benefits of Petroleum Coke for Industrial Applications

Summary:

Exploring the Benefits of Petroleum Coke for Industrial Applications

Table of Contents

1. Introduction to Petroleum Coke

2. Key Properties of Petroleum Coke

3. Industrial Applications of Petroleum Coke

3.1 Use in Anode Production

3.2 Fuel Source in Power Generation

3.3 Role in Cement Manufacturing

3.4 Benefit

Exploring the Benefits of Petroleum Coke for Industrial Applications

Table of Contents

- 1. Introduction to Petroleum Coke

- 2. Key Properties of Petroleum Coke

- 3. Industrial Applications of Petroleum Coke

- 3.1 Use in Anode Production

- 3.2 Fuel Source in Power Generation

- 3.3 Role in Cement Manufacturing

- 3.4 Benefits in Metallurgical Processes

- 4. Advantages of Using Petroleum Coke

- 5. Sourcing and Quality Control of Petroleum Coke

- 6. Safety Considerations in Handling Petroleum Coke

- 7. Future Trends in Petroleum Coke Usage

- 8. Conclusion

- 9. Frequently Asked Questions

1. Introduction to Petroleum Coke

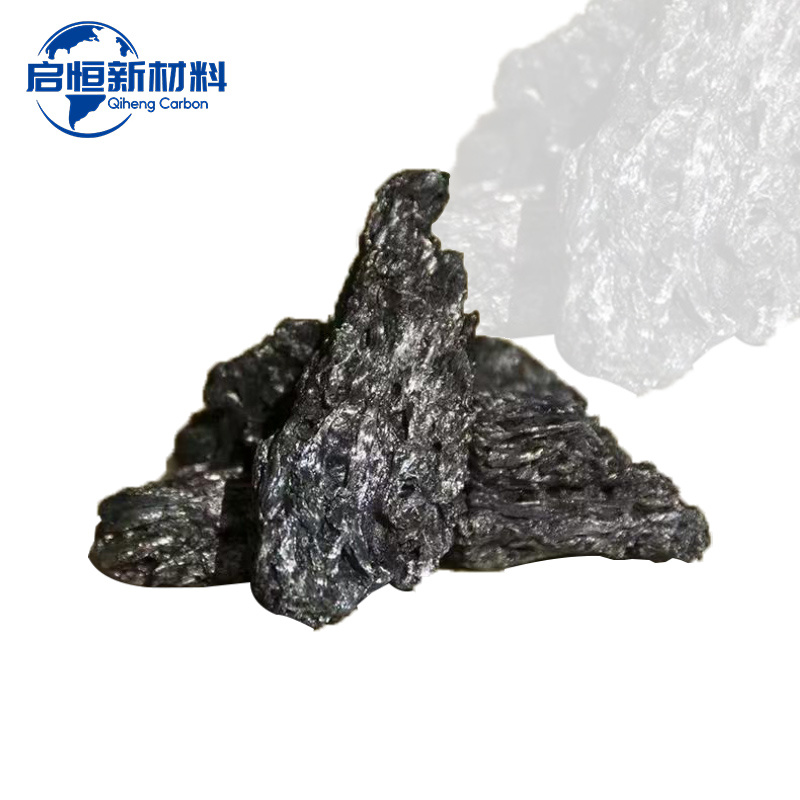

Petroleum coke, often referred to as petcoke, is a carbonaceous solid derived from oil refining and other industrial processes. It is a byproduct of the delayed coking process, where heavy hydrocarbons from crude oil are thermally cracked to produce lighter hydrocarbons and solid residues. With its high carbon content, petroleum coke has become a crucial material in various industrial applications, particularly in the production of anodes for aluminum smelting and as a fuel source for power generation.

2. Key Properties of Petroleum Coke

Petroleum coke exhibits several properties that make it suitable for industrial uses:

2.1 High Carbon Content

One of the most notable features of petroleum coke is its high carbon content, typically ranging from 80% to 90%. This property makes it a valuable source of carbon in metallurgical processes and a cleaner alternative to coal as a fuel source.

2.2 Low Sulfur Levels

Petroleum coke generally contains low sulfur levels, which is advantageous for applications that require minimal emissions of sulfur dioxide, a pollutant linked to acid rain.

2.3 Varied Particle Size

The particle size of petroleum coke can vary significantly, making it adaptable for different applications. It can be produced in fine particles or larger lumps, depending on the requirements of the end user.

3. Industrial Applications of Petroleum Coke

The versatility of petroleum coke allows it to be used in a wide range of industrial applications:

3.1 Use in Anode Production

One of the primary applications of petroleum coke is in the manufacture of anodes used in the aluminum smelting process. The high carbon content and low impurities of petcoke make it an ideal material for producing high-quality anodes, which are essential for efficient and effective aluminum production.

3.2 Fuel Source in Power Generation

Petroleum coke is increasingly being used as a fuel source in power generation. Its high calorific value and lower emissions compared to traditional fossil fuels make it a favored choice in many power plants. Additionally, its cost-effectiveness can lead to significant savings for energy providers.

3.3 Role in Cement Manufacturing

In the cement industry, petroleum coke is used as a fuel in kilns due to its high energy content. It allows manufacturers to produce cement more efficiently, while also contributing to the overall reduction of production costs.

3.4 Benefits in Metallurgical Processes

Petroleum coke plays a vital role in metallurgical processes, particularly in the production of steel. It is used as a reducing agent in the smelting of iron ore, helping to lower the temperature required for the process and ultimately leading to energy savings.

4. Advantages of Using Petroleum Coke

Utilizing petroleum coke in industrial applications offers several advantages:

4.1 Cost Efficiency

One of the most compelling reasons to use petroleum coke is its cost efficiency. As a byproduct of oil refining, it is often less expensive than other carbon sources, leading to reduced operational costs for businesses.

4.2 Environmental Benefits

Switching to petroleum coke can also yield environmental benefits. Its low sulfur content results in lower emissions of harmful pollutants, making it a more environmentally friendly option compared to other fossil fuels. Furthermore, utilizing petcoke can help industries meet stringent emission regulations.

4.3 Enhanced Performance

In processes such as aluminum production and power generation, petroleum coke can improve overall performance. Its high energy content and thermal stability can enhance efficiency, leading to higher productivity rates and better-quality products.

5. Sourcing and Quality Control of Petroleum Coke

Sourcing high-quality petroleum coke requires careful consideration of several factors. Companies must ensure consistency in quality, which can be achieved through rigorous testing and evaluation of petcoke from various suppliers. Monitoring characteristics such as sulfur content, volatile matter, and particle size is essential to ensure that the petroleum coke meets industry standards and operational requirements.

6. Safety Considerations in Handling Petroleum Coke

Although petroleum coke is generally safe to handle, it is essential to follow safety protocols to mitigate potential risks. Proper personal protective equipment (PPE) should be worn to prevent inhalation of dust and contact with skin. Additionally, ensuring adequate ventilation in storage areas can help reduce the accumulation of flammable dust.

7. Future Trends in Petroleum Coke Usage

As industries continue to seek sustainable and cost-effective solutions, the demand for petroleum coke is expected to grow. Innovations in refining processes and increased focus on carbon capture technologies will likely enhance the appeal of petcoke in a variety of applications. Furthermore, as stricter environmental regulations are implemented, industries may increasingly turn to petroleum coke as a cleaner alternative to conventional fuels.

8. Conclusion

In conclusion, petroleum coke presents numerous benefits for various industrial applications. Its high carbon content, cost-effectiveness, and environmental advantages make it an attractive choice for sectors such as aluminum production, power generation, and cement manufacturing. As industries evolve and adapt to changing regulations and market demands, the role of petroleum coke is likely to expand, further solidifying its importance in the industrial landscape.

9. Frequently Asked Questions

Q1: What is petroleum coke primarily used for?

A1: Petroleum coke is primarily used in the production of anodes for aluminum smelting, as a fuel source in power generation, and in cement manufacturing.

Q2: How does petroleum coke compare to coal as a fuel source?

A2: Petroleum coke generally has a higher calorific value and lower sulfur content than coal, making it a cleaner and more efficient alternative.

Q3: Is petroleum coke environmentally friendly?

A3: While petroleum coke is a fossil fuel, its low sulfur levels contribute to lower emissions of harmful pollutants, making it a more environmentally friendly option compared to other fossil fuels.

Q4: What safety precautions should be taken when handling petroleum coke?

A4: Safety precautions include wearing appropriate personal protective equipment (PPE), ensuring adequate ventilation in storage areas, and following proper handling protocols to minimize dust inhalation risks.

Q5: Are there any future trends in the use of petroleum coke?

A5: Yes, future trends may include increased adoption of petroleum coke due to its cost-effectiveness, advancements in refining processes, and greater focus on carbon capture technologies in response to stricter environmental regulations.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property