Unlocking the Potential of Graphite Powder in Metallurgy and Non-Metal Mineral Products

Summary:

Graphite powder is a versatile material used across various industries due to its unique properties, including high thermal conductivity, excellent lubricating qualities, and resistance to high temperatures. In the metallurgy sector, it is primarily used as a lubricant and a refractory material. Its ability to withstand extreme temperatures makes it an ideal choice for applications involving steel

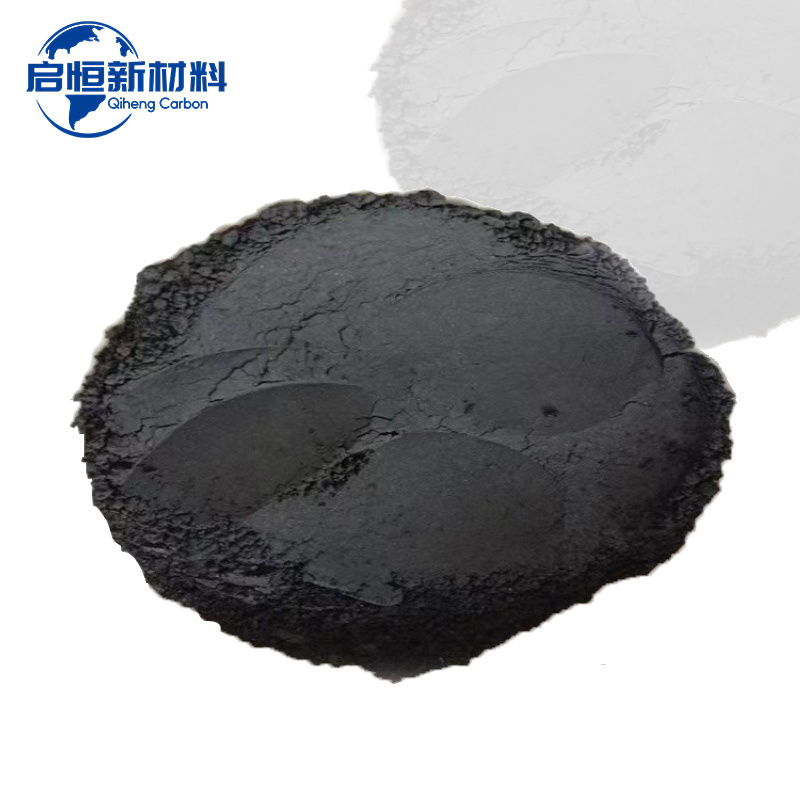

Graphite powder is a versatile material used across various industries due to its unique properties, including high thermal conductivity, excellent lubricating qualities, and resistance to high temperatures. In the metallurgy sector, it is primarily used as a lubricant and a refractory material. Its ability to withstand extreme temperatures makes it an ideal choice for applications involving steelmaking and casting processes.

One significant advantage of graphite powder in metallurgy is its role in promoting the efficiency of metal production. When added to metal formulations, it can improve the flow of molten metal and reduce friction during the casting process. This leads to better quality castings with fewer defects, ultimately enhancing the overall productivity of the metalworking industry.

In addition to its function in metal production, graphite powder is also essential in the production of non-metal mineral products. It serves as a critical component in the manufacturing of batteries, particularly in lithium-ion batteries, where it is used as an anode material. The increasing demand for electric vehicles and renewable energy storage solutions has spurred interest in the properties of graphite powder, making it a focal point in research and development efforts.

Moreover, the lubricating properties of graphite powder extend beyond metallurgy. It is commonly used in various industrial applications where lubrication is necessary, such as in machinery and equipment. Its ability to reduce friction and wear makes it a preferred choice for manufacturers looking to extend the lifespan of their products.

Furthermore, graphite powder is also utilized in the production of specialized coatings and composites. These materials benefit from the unique characteristics of graphite, including its electrical conductivity and thermal stability. As industries seek innovative materials to enhance performance, graphite powder continues to prove its worth across diverse applications.

Finally, the environmental aspect of graphite powder cannot be overlooked. As industries become more focused on sustainability, the use of natural graphite is gaining traction. Its biodegradable properties present an eco-friendly alternative compared to synthetic lubricants and other materials that may have a more significant environmental impact.

In conclusion, graphite powder is an indispensable material within the metallurgy and non-metal mineral products sectors. Its diverse applications, ranging from enhancing metal production processes to serving as a critical component in energy storage solutions, showcase its potential. As industries continue to innovate and evolve, the role of graphite powder will undoubtedly expand, solidifying its status as a key player in modern manufacturing and energy solutions.

One significant advantage of graphite powder in metallurgy is its role in promoting the efficiency of metal production. When added to metal formulations, it can improve the flow of molten metal and reduce friction during the casting process. This leads to better quality castings with fewer defects, ultimately enhancing the overall productivity of the metalworking industry.

In addition to its function in metal production, graphite powder is also essential in the production of non-metal mineral products. It serves as a critical component in the manufacturing of batteries, particularly in lithium-ion batteries, where it is used as an anode material. The increasing demand for electric vehicles and renewable energy storage solutions has spurred interest in the properties of graphite powder, making it a focal point in research and development efforts.

Moreover, the lubricating properties of graphite powder extend beyond metallurgy. It is commonly used in various industrial applications where lubrication is necessary, such as in machinery and equipment. Its ability to reduce friction and wear makes it a preferred choice for manufacturers looking to extend the lifespan of their products.

Furthermore, graphite powder is also utilized in the production of specialized coatings and composites. These materials benefit from the unique characteristics of graphite, including its electrical conductivity and thermal stability. As industries seek innovative materials to enhance performance, graphite powder continues to prove its worth across diverse applications.

Finally, the environmental aspect of graphite powder cannot be overlooked. As industries become more focused on sustainability, the use of natural graphite is gaining traction. Its biodegradable properties present an eco-friendly alternative compared to synthetic lubricants and other materials that may have a more significant environmental impact.

In conclusion, graphite powder is an indispensable material within the metallurgy and non-metal mineral products sectors. Its diverse applications, ranging from enhancing metal production processes to serving as a critical component in energy storage solutions, showcase its potential. As industries continue to innovate and evolve, the role of graphite powder will undoubtedly expand, solidifying its status as a key player in modern manufacturing and energy solutions.

Previous:

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property