How to Optimize Your Casting Process with Graphite Crucibles

Summary:

How to Optimize Your Casting Process with Graphite Crucibles

Table of Contents

1. Understanding Graphite Crucibles: The Key to Successful Metal Casting

2. Advantages of Using Graphite Crucibles in Casting Processes

3. Selecting the Right Graphite Crucible for Your Needs

3.1 Types of Graphite Crucibles and Their Applications

3.2 Factors to Consider When Choosing a Graphite Crucible

4.

How to Optimize Your Casting Process with Graphite Crucibles

Table of Contents

1. Understanding Graphite Crucibles: The Key to Successful Metal Casting

2. Advantages of Using Graphite Crucibles in Casting Processes

3. Selecting the Right Graphite Crucible for Your Needs

3.1 Types of Graphite Crucibles and Their Applications

3.2 Factors to Consider When Choosing a Graphite Crucible

4. Best Practices for Preparing and Using Graphite Crucibles

4.1 Proper Cleaning and Maintenance Techniques

4.2 Tips for Effective Heat Management

5. Troubleshooting Common Issues in Graphite Crucible Casting

5.1 Identifying and Resolving Contamination Problems

5.2 Avoiding Cracking and Breakage During Casting

6. Enhancing Casting Quality with Graphite Crucibles

6.1 Achieving Smooth Surface Finishes

6.2 Improving Metal Flow and Reducing Defects

7. The Future of Graphite Crucibles in Metal Casting

8. Frequently Asked Questions (FAQs)

9. Conclusion: Elevating Your Casting Process with Graphite Crucibles

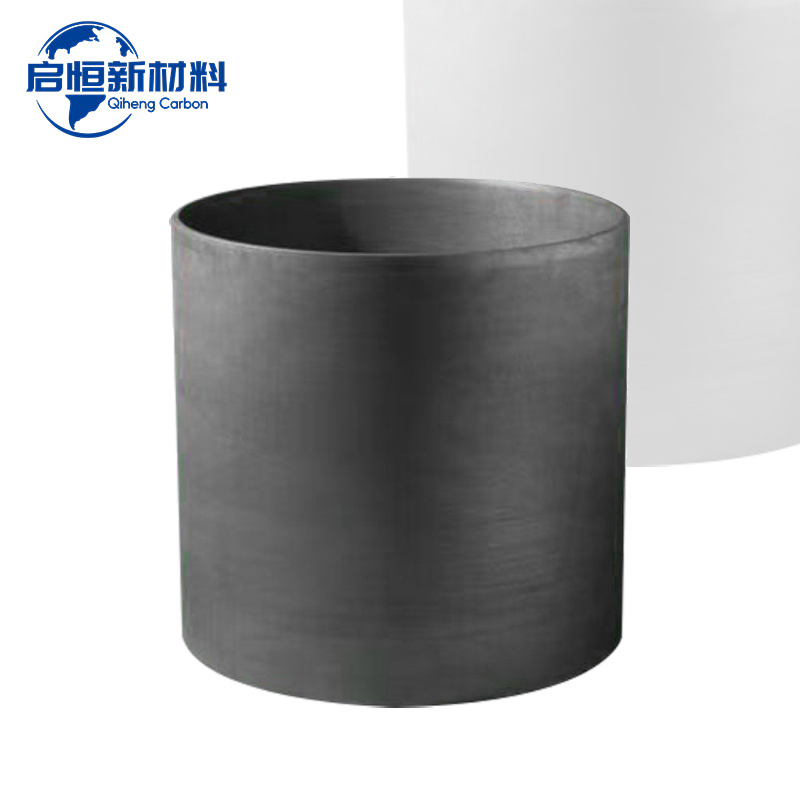

1. Understanding Graphite Crucibles: The Key to Successful Metal Casting

Graphite crucibles play a pivotal role in the metal casting process. Made from high-quality graphite, these crucibles are designed to withstand extreme temperatures and facilitate the melting of various metals, including aluminum, brass, and bronze. Their unique properties, such as excellent thermal conductivity and resistance to thermal shock, make them indispensable in the metallurgical industry.

As we delve deeper into the subject, it becomes evident that optimizing your casting process with graphite crucibles is not just about selecting the right crucible but also about understanding the intricacies of their application. By focusing on the optimization techniques outlined in this guide, you can significantly enhance your casting outcomes.

2. Advantages of Using Graphite Crucibles in Casting Processes

Graphite crucibles offer numerous advantages over traditional metal or ceramic crucibles. Here are some of the most notable benefits:

- **High Thermal Conductivity**: Graphite conducts heat more efficiently than other materials, allowing for quicker melting times and reducing energy consumption.

- **Thermal Shock Resistance**: Graphite crucibles can endure rapid temperature changes without cracking, providing greater reliability during the casting process.

- **Chemical Resistance**: They resist many corrosive materials, preventing contamination of the molten metal.

- **Low Loss of Metal**: With their smooth surfaces, graphite crucibles minimize metal loss due to sticking or adherence, leading to cost-effective operations.

By understanding these advantages, you can leverage graphite crucibles to optimize your casting process and improve overall productivity.

3. Selecting the Right Graphite Crucible for Your Needs

Choosing the appropriate graphite crucible is critical to the success of your casting operations. The right crucible can influence not only the melting efficiency but also the quality of your final product.

3.1 Types of Graphite Crucibles and Their Applications

There are several types of graphite crucibles tailored for specific applications. Common varieties include:

- **High-Density Graphite Crucibles**: Ideal for melting ferrous and non-ferrous metals due to their ability to withstand higher temperatures.

- **Low-Density Graphite Crucibles**: Suited for lighter metals, these crucibles provide excellent heat retention while being cost-effective.

- **Specialty Graphite Crucibles**: Designed for specific alloys or unique melting requirements, these crucibles offer tailored solutions for advanced casting processes.

3.2 Factors to Consider When Choosing a Graphite Crucible

When selecting a graphite crucible, several factors should be considered:

- **Size and Capacity**: Ensure the crucible's volume aligns with your melting requirements.

- **Temperature Rating**: Select a crucible capable of enduring the temperatures required for your specific metal.

- **Purity**: High-purity graphite crucibles are essential to minimize contamination in sensitive casting applications.

- **Shape and Design**: Some designs facilitate better heat distribution and easier pouring, which can enhance your casting efficiency.

Understanding these factors will help you choose the right crucible for your specific needs.

4. Best Practices for Preparing and Using Graphite Crucibles

To maximize the performance of your graphite crucibles, adhering to best practices during preparation and usage is essential.

4.1 Proper Cleaning and Maintenance Techniques

Before using a graphite crucible, it’s crucial to clean it thoroughly. Here are some steps to follow:

1. **Remove Residues**: Gently scrape off any leftover materials from previous casts using a non-abrasive tool.

2. **Rinse with Solvents**: Wash the crucible with an appropriate solvent to eliminate any chemical residues.

3. **Dry Completely**: Ensure the crucible is fully dried before heating to avoid moisture-related issues.

Regular maintenance extends the lifespan of your crucible and ensures consistent performance.

4.2 Tips for Effective Heat Management

Managing heat effectively can enhance the performance of your graphite crucibles. Consider the following tips:

- **Preheat the Crucible**: Gradually preheating the crucible can minimize thermal shock and help achieve a more uniform melting temperature.

- **Control the Heat Source**: Adjust the intensity of your heat source based on the specific metal being melted to avoid overheating or underheating.

- **Monitor Metal Temperature**: Utilize thermocouples or infrared sensors to keep track of the metal temperature during the melting process.

Implementing these heat management techniques will lead to better casting quality and reduced material waste.

5. Troubleshooting Common Issues in Graphite Crucible Casting

Even with the best practices in place, issues can arise during the casting process. Here, we explore common problems and their solutions.

5.1 Identifying and Resolving Contamination Problems

Contamination can severely affect the integrity of your castings. Common sources include:

- **Foreign Materials**: Dust, dirt, or residues from previous melts can contaminate the molten metal.

- **Improper Cleaning**: Inadequate cleaning of the crucible may lead to residual materials interfering with the casting process.

To combat contamination, ensure meticulous cleaning of both the crucibles and the work environment.

5.2 Avoiding Cracking and Breakage During Casting

Graphite crucibles are susceptible to cracking if not handled correctly. To minimize risks:

- **Gradual Temperature Changes**: Avoid sudden temperature shifts, which can cause thermal stress.

- **Proper Handling**: Use appropriate tools and techniques when moving and pouring from crucibles to prevent physical damage.

Implementing these strategies will help maintain the integrity of your crucibles.

6. Enhancing Casting Quality with Graphite Crucibles

Employing graphite crucibles effectively can lead to superior casting quality. Here’s how:

6.1 Achieving Smooth Surface Finishes

The smooth interior surface of graphite crucibles contributes to fewer imperfections in the final product. To enhance surface quality:

- **Maintain Crucible Condition**: Regular cleaning and proper maintenance will keep the surface in optimal condition.

- **Optimize Pouring Techniques**: Pouring at the correct angle and speed can reduce turbulence and improve surface finish.

6.2 Improving Metal Flow and Reducing Defects

Graphite crucibles facilitate better metal flow due to their thermal properties. To further enhance this:

- **Use Appropriate Fluxes**: Incorporating fluxes can aid in reducing oxidation and improving fluidity.

- **Control Pouring Temperature**: Maintaining an optimal pouring temperature will enhance metal flow and reduce defects.

Emphasizing these factors will ensure high-quality casting results.

7. The Future of Graphite Crucibles in Metal Casting

The evolution of graphite crucibles continues to impact the metal casting industry. Innovations in materials and design are paving the way for more efficient and specialized crucibles. As industries seek to improve sustainability and reduce costs, the role of advanced graphite materials will become increasingly significant. Keeping abreast of these developments will empower you to stay competitive in the market.

8. Frequently Asked Questions (FAQs)

**1. What distinguishes graphite crucibles from other types of crucibles?**

Graphite crucibles excel in thermal conductivity, resistance to thermal shock, and reduced oxidation compared to metal or ceramic crucibles, making them ideal for high-temperature applications.

**2. How can I extend the lifespan of my graphite crucibles?**

Regular cleaning, proper maintenance, gradual heating and cooling, and careful handling can significantly prolong the life of your graphite crucibles.

**3. Are there specific temperatures at which graphite crucibles perform best?**

Graphite crucibles can typically withstand temperatures exceeding 1500°C (2732°F). However, optimal performance varies based on the specific type and application.

**4. What maintenance practices should I implement for my graphite crucibles?**

Key maintenance practices include thorough cleaning after each use, avoiding sudden temperature changes, and checking for any signs of wear or damage regularly.

**5. Can I use graphite crucibles for casting different metals?**

Yes, graphite crucibles are versatile and can be used for various metals, including aluminum, zinc, brass, and bronze, with considerations for temperature and metal properties.

9. Conclusion: Elevating Your Casting Process with Graphite Crucibles

Optimizing your casting process with graphite crucibles involves understanding their unique properties, selecting the appropriate type, and implementing best practices for usage and maintenance. By focusing on these elements, you can enhance the efficiency and quality of your casting operations, ultimately leading to improved product outcomes and cost savings. Staying informed about advancements in graphite crucible technology will further empower you to achieve excellence in the metallurgical field.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property