Understanding Calcined Petroleum Coke: Key Insights for Professionals in the Chemical Industry

Summary:

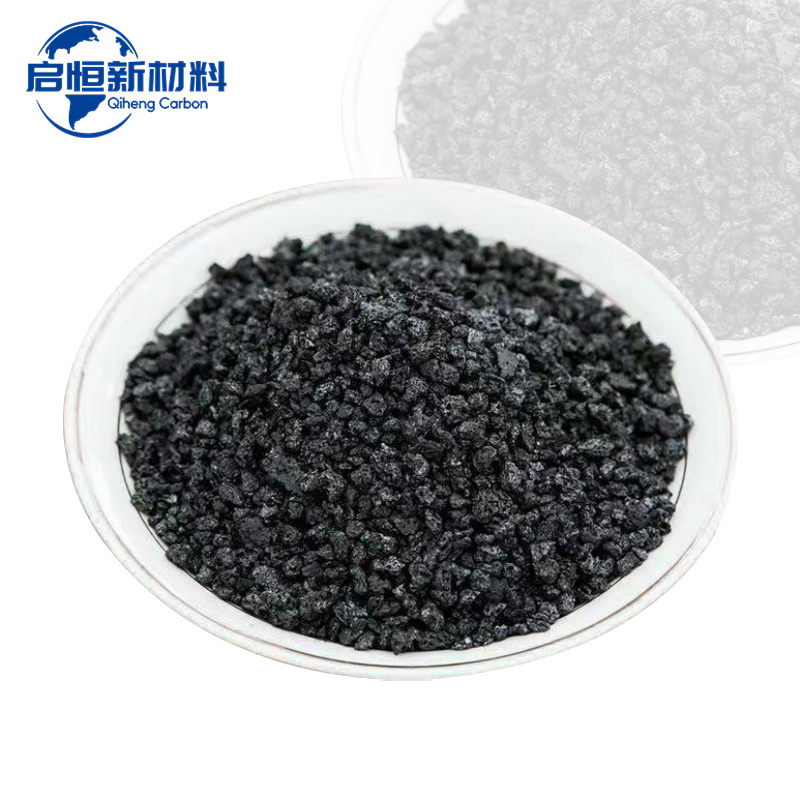

Calcined petroleum coke (CPC) is a crucial intermediate product derived from the thermal treatment of green petroleum coke. This process involves heating the green coke in a controlled environment to remove volatile components, resulting in a dense, carbon-rich material. The calcination process typically occurs at temperatures ranging from 1200°C to 1350°C, which not only enhances the carbon conte

Calcined petroleum coke (CPC) is a crucial intermediate product derived from the thermal treatment of green petroleum coke. This process involves heating the green coke in a controlled environment to remove volatile components, resulting in a dense, carbon-rich material. The calcination process typically occurs at temperatures ranging from 1200°C to 1350°C, which not only enhances the carbon content but also improves the conductivity and structural integrity of the resulting product.

One of the primary applications of calcined petroleum coke is in the aluminum industry, where it serves as a key precursor for the production of anodes used in the electrolytic process of aluminum smelting. The high purity and low sulfur content of CPC make it an ideal choice in this application, as it ensures the efficiency and quality of aluminum production. Additionally, CPC is used in the manufacturing of carbon products, such as graphite electrodes, which are essential in electric arc furnaces for steel production.

Furthermore, calcined petroleum coke plays a significant role in the production of various chemicals and fuels. Its high carbon content and low impurities make it suitable for use in the production of carbon black, a vital ingredient in tires, coatings, and plastics. The demand for calcined petroleum coke in these sectors continues to grow, driven by the expanding automotive and construction industries.

In terms of environmental considerations, the production and utilization of calcined petroleum coke have prompted discussions regarding sustainability and emissions. As industries strive to reduce their carbon footprint, there is an increasing focus on optimizing the calcination process to minimize energy consumption and emissions. Innovative technologies and practices are being explored to enhance the efficiency of CPC production while mitigating environmental impacts.

For professionals in the chemical and petroleum sectors, understanding the properties and applications of calcined petroleum coke is essential for making informed decisions regarding material sourcing and utilization. As the industry evolves, staying updated on market trends and technological advancements related to CPC will be crucial for maintaining a competitive edge.

In conclusion, calcined petroleum coke is a vital material with diverse applications across various industries. Its unique properties and significant role in aluminum production, chemical manufacturing, and carbon products highlight its importance in the chemical and petroleum sectors. As sustainability becomes a focal point, continued advancements in the production and application of CPC will shape its future in the global market.

One of the primary applications of calcined petroleum coke is in the aluminum industry, where it serves as a key precursor for the production of anodes used in the electrolytic process of aluminum smelting. The high purity and low sulfur content of CPC make it an ideal choice in this application, as it ensures the efficiency and quality of aluminum production. Additionally, CPC is used in the manufacturing of carbon products, such as graphite electrodes, which are essential in electric arc furnaces for steel production.

Furthermore, calcined petroleum coke plays a significant role in the production of various chemicals and fuels. Its high carbon content and low impurities make it suitable for use in the production of carbon black, a vital ingredient in tires, coatings, and plastics. The demand for calcined petroleum coke in these sectors continues to grow, driven by the expanding automotive and construction industries.

In terms of environmental considerations, the production and utilization of calcined petroleum coke have prompted discussions regarding sustainability and emissions. As industries strive to reduce their carbon footprint, there is an increasing focus on optimizing the calcination process to minimize energy consumption and emissions. Innovative technologies and practices are being explored to enhance the efficiency of CPC production while mitigating environmental impacts.

For professionals in the chemical and petroleum sectors, understanding the properties and applications of calcined petroleum coke is essential for making informed decisions regarding material sourcing and utilization. As the industry evolves, staying updated on market trends and technological advancements related to CPC will be crucial for maintaining a competitive edge.

In conclusion, calcined petroleum coke is a vital material with diverse applications across various industries. Its unique properties and significant role in aluminum production, chemical manufacturing, and carbon products highlight its importance in the chemical and petroleum sectors. As sustainability becomes a focal point, continued advancements in the production and application of CPC will shape its future in the global market.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property