The Pivotal Role of Graphite Electrode Connectors in Revolutionary Electrical Engineering

Summary:

The Pivotal Role of Graphite Electrode Connectors in Revolutionary Electrical Engineering

Table of Contents

Introduction to Graphite Electrode Connectors

Understanding Graphite and Its Properties

The Importance of Connectors in Electrical Engineering

Key Features of Graphite Electrode Connectors

Applications of Graphite Electrode Connectors in Various Industries

The Pivotal Role of Graphite Electrode Connectors in Revolutionary Electrical Engineering

Table of Contents

- Introduction to Graphite Electrode Connectors

- Understanding Graphite and Its Properties

- The Importance of Connectors in Electrical Engineering

- Key Features of Graphite Electrode Connectors

- Applications of Graphite Electrode Connectors in Various Industries

- Advantages of Using Graphite Electrode Connectors

- Innovations in Graphite Electrode Connector Technology

- Challenges and Solutions in Implementing Graphite Connectors

- The Future of Graphite Electrode Connectors in Electrical Engineering

- Frequently Asked Questions (FAQs)

- Conclusion

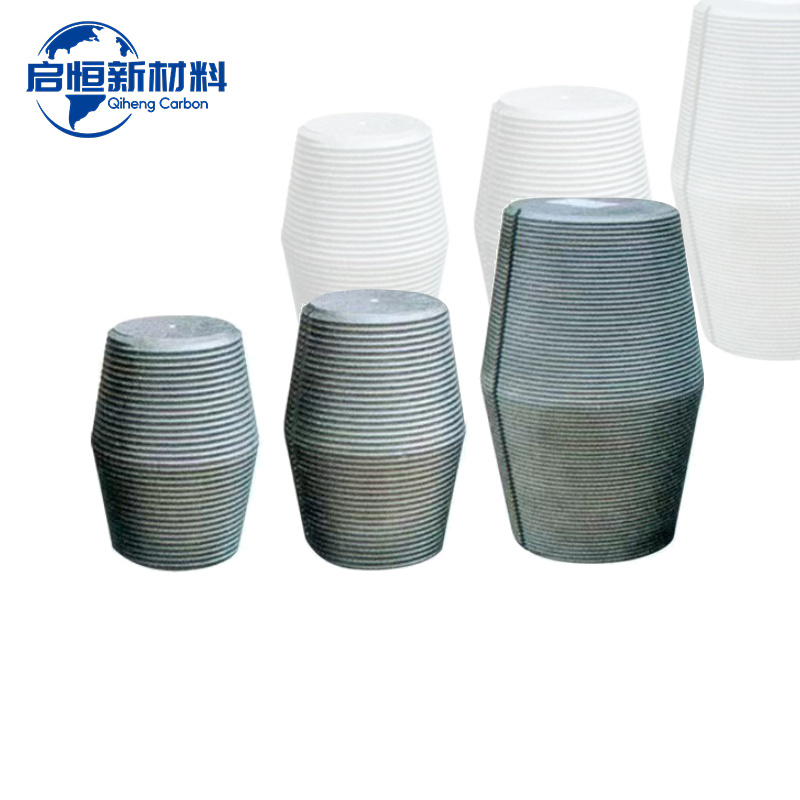

Introduction to Graphite Electrode Connectors

In the ever-evolving landscape of electrical engineering, **graphite electrode connectors** have emerged as a crucial component that enhances the efficiency and reliability of electrical systems. These connectors are not merely components; they are integral to the functionality of various electrical applications, serving as the backbone of effective electrical connections. As we delve into the role of graphite electrode connectors, we uncover their multifaceted benefits and indispensable applications across different sectors.

Understanding Graphite and Its Properties

Graphite is a naturally occurring form of carbon that exhibits unique properties, making it invaluable in numerous industrial applications. Its **excellent electrical conductivity**, **thermal stability**, and **resistance to corrosion** position it as an ideal material for connectors. Graphite's layered structure allows for easy electron flow, which is essential in electrical connections. Additionally, its high melting point and ability to withstand extreme temperatures further enhance its utility in electrical engineering.

The Unique Characteristics of Graphite

Graphite possesses several key characteristics that contribute to its effectiveness in electrical applications:

- **Conductivity:** Graphite is one of the best conductors of electricity, allowing for minimal resistance in electrical circuits.

- **Flexibility:** The material can be molded and shaped to fit various connector designs.

- **Resistance to Chemical Corrosion:** Graphite connectors can withstand harsh chemical environments, making them suitable for diverse industrial applications.

- **Thermal Stability:** The ability to maintain performance under high temperatures is crucial for many electrical applications.

The Importance of Connectors in Electrical Engineering

Connectors are essential components in any electrical system, serving as the points of connection between different electrical devices. They facilitate the flow of electrical currents, ensuring that devices communicate effectively with one another. The reliability of these connections directly impacts the overall performance of electrical systems. In this regard, the use of high-quality connectors, such as those made from graphite, can significantly improve performance and durability.

The Role of Connectors in Circuit Reliability

Reliable connections are vital for preventing issues such as signal loss, overheating, and equipment failure. Poorly designed connectors can lead to inefficiencies, increased maintenance costs, and even safety hazards. Graphite electrode connectors address these issues by providing a stable and efficient means of connection, thus enhancing the reliability of electrical circuits.

Key Features of Graphite Electrode Connectors

Graphite electrode connectors come with several features that distinguish them from traditional connectors:

- **High Voltage Tolerance:** They can handle high voltage levels without degrading, making them suitable for various applications.

- **Durability:** Graphite's inherent properties provide long-lasting performance, reducing the need for frequent replacements.

- **Minimal Maintenance:** The robustness of graphite connectors leads to reduced maintenance needs, saving time and resources.

- **Adaptability:** Their design can be customized to meet specific application requirements, ensuring compatibility with various systems.

Applications of Graphite Electrode Connectors in Various Industries

Graphite electrode connectors find applications across a wide array of industries, showcasing their versatility. Some prominent applications include:

1. Power Generation and Distribution

In power generation facilities, graphite connectors are used in high-voltage applications, ensuring efficient energy transmission. Their ability to withstand extreme conditions makes them ideal for use in power plants and substations.

2. Automotive Industry

Automotive manufacturers utilize graphite connectors in electric vehicles (EVs) and hybrid models, where efficient electrical connections are paramount for performance and safety.

3. Electronics and Telecommunications

In the electronics sector, graphite connectors enhance signal integrity in communication devices, contributing to faster and more reliable data transmission.

4. Aerospace Engineering

Aerospace applications require connectors that can withstand harsh environmental conditions. Graphite connectors provide the necessary reliability and performance for critical systems in aircraft.

5. Industrial Automation

Automation systems benefit from the adaptability and durability of graphite connectors, which are essential for maintaining seamless operations in manufacturing processes.

Advantages of Using Graphite Electrode Connectors

The benefits of integrating graphite electrode connectors into electrical systems are numerous:

1. Increased Efficiency

The low resistance offered by graphite connectors leads to improved energy efficiency, reducing energy losses during transmission.

2. Enhanced Performance

Graphite connectors contribute to optimal device performance, ensuring that systems operate effectively without interruptions.

3. Cost-Effectiveness

With reduced maintenance needs and longer lifespan, the overall cost of ownership for systems using graphite connectors is significantly lower.

4. Safety and Reliability

The robustness of graphite connectors translates to enhanced safety in electrical systems, minimizing the risk of failures and hazards.

Innovations in Graphite Electrode Connector Technology

As technology advances, so do the innovations in graphite electrode connector design and functionality. Manufacturers are continually researching ways to enhance performance and adaptability. Notable innovations include:

1. Conductive Coatings

The application of advanced conductive coatings on graphite connectors improves conductivity and reduces wear over time.

2. Modular Designs

Modular designs allow for easier customization and scalability, making it easier to adapt connectors for various applications.

3. Smart Connectors

Integration of smart technologies into connectors enables monitoring of performance metrics, enhancing diagnostics and predictive maintenance capabilities.

Challenges and Solutions in Implementing Graphite Connectors

While graphite electrode connectors offer numerous advantages, there are challenges associated with their implementation:

1. Cost of Material

The initial cost of graphite can be higher than traditional materials. However, the long-term savings in maintenance and replacement costs typically offset this initial investment.

2. Installation Complexity

The installation process may require specialized training. Investing in proper training programs for technicians can mitigate this challenge.

3. Compatibility with Existing Systems

Ensuring compatibility with existing electrical systems is crucial. Conducting thorough compatibility assessments before implementation can help avoid integration issues.

The Future of Graphite Electrode Connectors in Electrical Engineering

The future of graphite electrode connectors appears bright, with ongoing advancements in materials science and engineering practices. As industries increasingly prioritize efficiency and sustainability, the demand for innovative connector solutions is expected to grow. Future trends may include:

- Greater emphasis on eco-friendly materials and manufacturing processes.

- Development of more efficient conductive materials that integrate seamlessly with graphite.

- Enhanced focus on the Internet of Things (IoT) connectivity, leading to smarter electrical systems.

Frequently Asked Questions (FAQs)

1. What are graphite electrode connectors used for?

Graphite electrode connectors are used in various applications, including power generation, automotive, aerospace, and industrial automation, providing reliable electrical connections.

2. How do graphite connectors improve electrical efficiency?

Their low resistance and excellent conductivity allow for minimal energy loss during transmission, enhancing overall efficiency.

3. Are graphite connectors suitable for high-voltage applications?

Yes, graphite connectors are designed to handle high voltage levels, making them suitable for demanding electrical systems.

4. What is the lifespan of graphite electrode connectors?

Due to their durability and resistance to wear, graphite connectors typically have a long lifespan, reducing the need for frequent replacements.

5. Can graphite connectors be customized for specific applications?

Absolutely. Graphite connectors can be designed and manufactured to meet the specific requirements of various applications.

Conclusion

In summary, graphite electrode connectors play a pivotal role in modern electrical engineering, offering unparalleled advantages in conductivity, durability, and adaptability. As industries continue to evolve towards more efficient and reliable electrical systems, the significance of these connectors will undoubtedly grow. By embracing the innovations and addressing the challenges associated with graphite connectors, we can ensure a more sustainable and effective future in electrical engineering. Their adaptability across various sectors underscores their importance, making them a key component in the ongoing quest for electrical excellence.

Previous:

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property