Unlocking the Benefits of UHP Graphite Electrodes in Aerospace Manufacturing

Summary:

Unlocking the Benefits of UHP Graphite Electrodes in Aerospace Manufacturing

Table of Contents

1. Introduction to UHP Graphite Electrodes

2. Understanding UHP Graphite Electrodes

3. Key Advantages of UHP Graphite Electrodes in Aerospace

3.1 High Temperature Resistance

3.2 Excellent Electrical Conductivity

3.3 Low Thermal Expansion

3.4 Mechanical Strength

3.5 Cost Efficiency

4. App

Unlocking the Benefits of UHP Graphite Electrodes in Aerospace Manufacturing

Table of Contents

- 1. Introduction to UHP Graphite Electrodes

- 2. Understanding UHP Graphite Electrodes

- 3. Key Advantages of UHP Graphite Electrodes in Aerospace

- 3.1 High Temperature Resistance

- 3.2 Excellent Electrical Conductivity

- 3.3 Low Thermal Expansion

- 3.4 Mechanical Strength

- 3.5 Cost Efficiency

- 4. Applications in Aerospace Manufacturing

- 5. Environmental Considerations

- 6. Future Trends in UHP Graphite Electrodes

- 7. Frequently Asked Questions

- 8. Conclusion

1. Introduction to UHP Graphite Electrodes

The aerospace manufacturing industry demands materials that can withstand extreme conditions while maintaining performance and reliability. Ultra High Power (UHP) graphite electrodes have emerged as a vital component in this sector due to their exceptional properties. They play a crucial role in processes like electrical discharge machining (EDM) and electric arc furnaces, delivering precision and durability. As we delve deeper into the benefits of UHP graphite electrodes, we will uncover why they are increasingly favored in aerospace applications.

2. Understanding UHP Graphite Electrodes

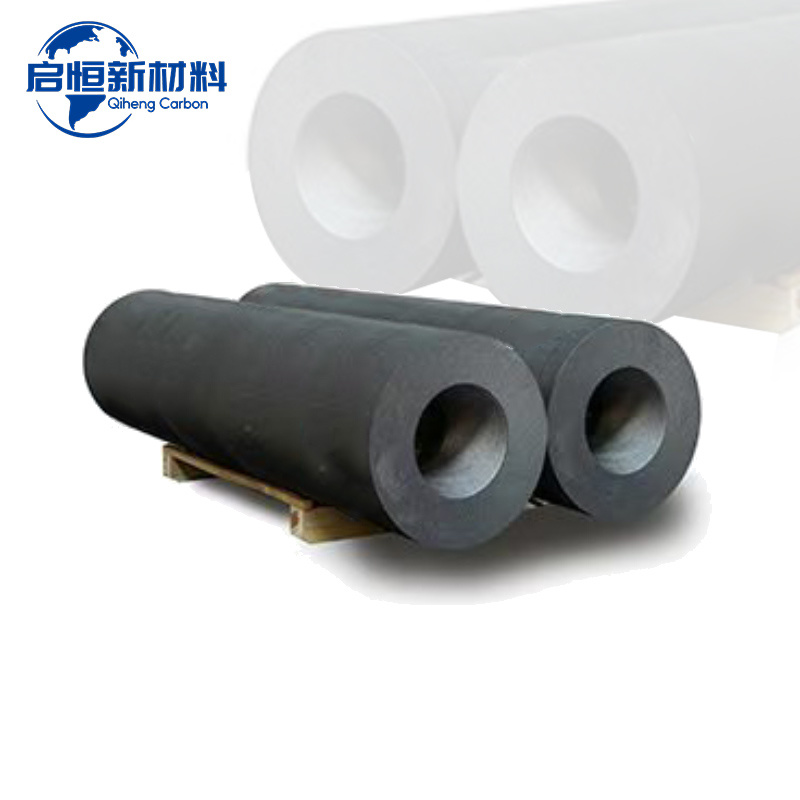

UHP graphite electrodes are manufactured from high-quality petroleum needle coke and are designed to endure high currents for long durations. This process significantly enhances their electrical and thermal conductivity, making them suitable for high-temperature applications. Unlike standard graphite electrodes, UHP electrodes offer superior performance, making them ideal for the demands of modern aerospace manufacturing.

3. Key Advantages of UHP Graphite Electrodes in Aerospace

3.1 High Temperature Resistance

One of the standout features of UHP graphite electrodes is their ability to withstand high temperatures without losing structural integrity. In aerospace manufacturing, components often undergo extreme thermal cycles, and UHP electrodes can perform reliably under such conditions. This resistance to thermal degradation ensures that the manufacturing process can proceed without interruptions, leading to higher productivity and lower operational costs.

3.2 Excellent Electrical Conductivity

UHP graphite electrodes exhibit exceptional electrical conductivity, a critical requirement for many aerospace applications. Their ability to conduct electricity efficiently allows for precise electrical discharge machining, which is essential in creating intricate designs and maintaining tight tolerances. This enhanced conductivity also contributes to reduced energy consumption, making the manufacturing process more efficient and environmentally friendly.

3.3 Low Thermal Expansion

Another significant advantage of UHP graphite electrodes is their low coefficient of thermal expansion. This property minimizes changes in size and shape during temperature fluctuations, ensuring that manufactured components maintain their precision. In aerospace, where even the slightest deviation can have serious consequences, this characteristic is invaluable for maintaining the integrity of components.

3.4 Mechanical Strength

UHP graphite electrodes possess impressive mechanical strength, allowing them to endure the stresses of high-speed machining and other demanding processes. This strength translates to longer tool life, reducing the frequency of replacements and downtime in manufacturing operations. The durability of UHP electrodes makes them a cost-effective choice for aerospace manufacturers looking to optimize performance.

3.5 Cost Efficiency

While the initial investment in UHP graphite electrodes may be higher than traditional options, their long-term cost-effectiveness is undeniable. The combination of enhanced performance, reduced downtime, and lower energy consumption contributes to overall savings in the manufacturing process. By choosing UHP electrodes, aerospace manufacturers can achieve a better return on investment while maintaining high-quality production standards.

4. Applications in Aerospace Manufacturing

UHP graphite electrodes are utilized in various applications within aerospace manufacturing, including:

1. **Electrical Discharge Machining (EDM)**: UHP electrodes are primarily used in EDM processes to create complex shapes in hard materials. Their ability to withstand high temperatures and maintain electrical conductivity makes them ideal for this application.

2. **Mold Making**: Aerospace components often require precise molds, and UHP graphite electrodes can produce intricate details with high accuracy. Their wear resistance ensures that molds can be used multiple times without significant degradation.

3. **Heat Treatment**: In the heat treatment of aerospace components, UHP electrodes are used to generate the necessary heat for processes like quenching and tempering, providing superior temperature control.

4. **Additive Manufacturing**: As the aerospace industry leans more towards additive manufacturing, UHP graphite electrodes are increasingly important for creating components with complex geometries and lightweight characteristics.

5. Environmental Considerations

The aerospace industry is under constant scrutiny regarding its environmental impact. UHP graphite electrodes contribute positively in this aspect by promoting energy-efficient processes. Their long lifespan and reduced waste generation align with sustainability goals, making them a preferred choice for environmentally conscious manufacturers. Additionally, advancements in recycling technologies for graphite materials are further reducing the ecological footprint of UHP electrodes.

6. Future Trends in UHP Graphite Electrodes

The future of UHP graphite electrodes in aerospace manufacturing looks promising. Ongoing research and development are focused on enhancing their properties, such as improving thermal conductivity and reducing production costs. Moreover, as aerospace technology continues to advance, we can expect UHP electrodes to play an even more significant role in emerging manufacturing techniques. The integration of smart technologies, such as IoT and AI, may also optimize the performance and monitoring of UHP electrodes during manufacturing processes.

7. Frequently Asked Questions

What are UHP graphite electrodes?

UHP graphite electrodes are specialized electrodes made from high-quality petroleum needle coke, designed for high electrical and thermal conductivity. They are primarily used in electrical discharge machining and electric arc furnaces.

How do UHP graphite electrodes compare to standard electrodes?

UHP graphite electrodes outperform standard electrodes in terms of electrical conductivity, thermal resistance, and mechanical strength. They are specifically engineered for demanding applications, making them more suitable for aerospace manufacturing.

What advantages do UHP graphite electrodes offer in aerospace manufacturing?

UHP graphite electrodes provide high temperature resistance, excellent electrical conductivity, low thermal expansion, mechanical strength, and cost efficiency, making them essential in aerospace manufacturing processes.

What applications utilize UHP graphite electrodes in aerospace?

UHP graphite electrodes are commonly used in electrical discharge machining (EDM), mold making, heat treatment, and additive manufacturing within the aerospace sector.

Are there environmental benefits to using UHP graphite electrodes?

Yes, UHP graphite electrodes promote energy efficiency and sustainability in aerospace manufacturing due to their long lifespan, reduced waste, and potential for recycling.

8. Conclusion

The advantages of UHP graphite electrodes in aerospace manufacturing are clear and compelling. Their unique properties offer solutions to the industry's most pressing challenges, from high-temperature resistance to exceptional electrical conductivity. As the aerospace sector continues to evolve, UHP graphite electrodes will remain at the forefront, enabling manufacturers to achieve greater efficiency, precision, and sustainability. Investing in UHP electrodes not only enhances manufacturing processes but also positions companies for future advancements in aerospace technology. Embracing the potential of UHP graphite electrodes is essential for manufacturers looking to thrive in a competitive landscape.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property