Understanding Graphite Powder: Applications, Properties, and Benefits

Summary:

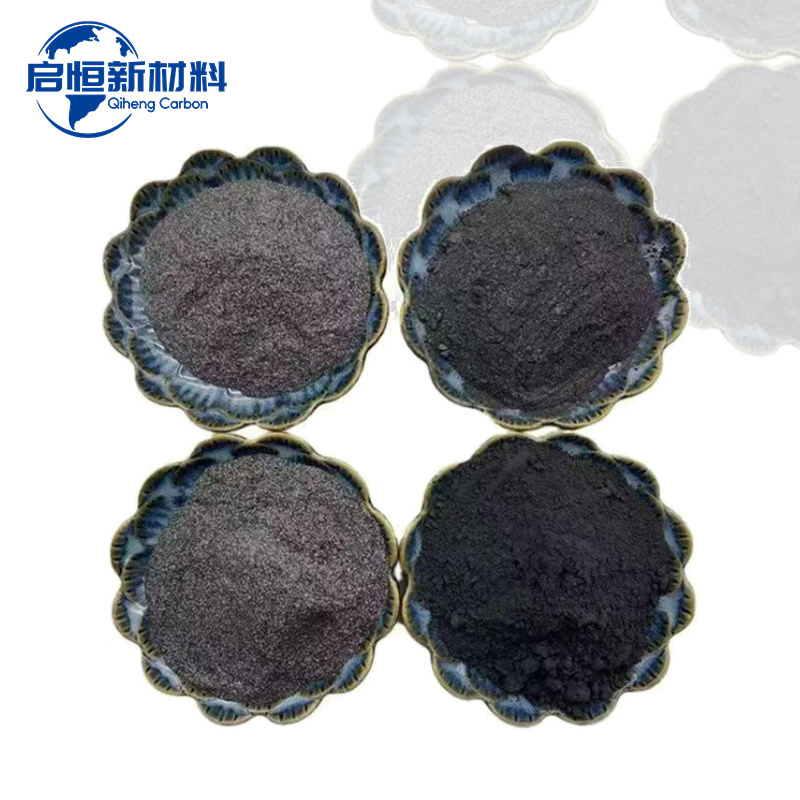

Graphite powder is a finely ground form of graphite, a naturally occurring form of carbon that possesses unique physical and chemical properties. Its applications span a wide range of industries, particularly in metallurgy and energy sectors. Understanding the characteristics and uses of graphite powder can highlight its significance and versatility.

One of the key properties of graphite powder is

Graphite powder is a finely ground form of graphite, a naturally occurring form of carbon that possesses unique physical and chemical properties. Its applications span a wide range of industries, particularly in metallurgy and energy sectors. Understanding the characteristics and uses of graphite powder can highlight its significance and versatility.

One of the key properties of graphite powder is its excellent thermal and electrical conductivity. This makes it an ideal material for applications that require efficient heat and electricity transfer. In metallurgy, graphite powder is often used as a lubricant in high-temperature processes, enabling smoother operation and reducing wear on machinery. This characteristic also makes it suitable for use in batteries, where efficient energy transfer is crucial.

Another important property of graphite powder is its chemical inertness. Graphite is resistant to most chemicals, which makes it a valuable component in various industrial processes. For instance, it is used in the production of refractory materials that can withstand high temperatures without reacting with other elements. This characteristic is essential in sectors such as foundries and steel production, where high-performance materials are needed.

Graphite powder's lubricating properties also extend its use beyond metallurgy. It is often employed in the production of lubricants and greases, where it enhances the performance of the final product. Additionally, it is used in the manufacturing of pencils, paints, and coatings due to its ability to provide smooth application and enhance durability.

Environmental considerations have also led to increased interest in graphite powder. As industries seek sustainable and eco-friendly materials, graphite, being a naturally occurring substance, presents an attractive option. Its use in energy storage solutions, particularly in lithium-ion batteries, aligns with the growing demand for renewable energy technologies. As the world moves towards cleaner energy sources, the demand for graphite powder is expected to rise, making it a critical material in the transition to sustainable practices.

Moreover, the production processes of graphite powder can vary, with methods such as grinding and milling being common. The quality and purity of graphite powder can significantly influence its performance in various applications. Therefore, choosing high-quality graphite powder is essential for industries that rely on its unique properties.

In conclusion, graphite powder serves as an essential material in various industries, particularly in metallurgy and energy sectors. Its unique properties, such as thermal and electrical conductivity, chemical inertness, and lubricating qualities, highlight its versatility and importance in modern manufacturing processes. As industries evolve towards sustainable practices, graphite powder will continue to play a crucial role in facilitating advancements across multiple sectors.

One of the key properties of graphite powder is its excellent thermal and electrical conductivity. This makes it an ideal material for applications that require efficient heat and electricity transfer. In metallurgy, graphite powder is often used as a lubricant in high-temperature processes, enabling smoother operation and reducing wear on machinery. This characteristic also makes it suitable for use in batteries, where efficient energy transfer is crucial.

Another important property of graphite powder is its chemical inertness. Graphite is resistant to most chemicals, which makes it a valuable component in various industrial processes. For instance, it is used in the production of refractory materials that can withstand high temperatures without reacting with other elements. This characteristic is essential in sectors such as foundries and steel production, where high-performance materials are needed.

Graphite powder's lubricating properties also extend its use beyond metallurgy. It is often employed in the production of lubricants and greases, where it enhances the performance of the final product. Additionally, it is used in the manufacturing of pencils, paints, and coatings due to its ability to provide smooth application and enhance durability.

Environmental considerations have also led to increased interest in graphite powder. As industries seek sustainable and eco-friendly materials, graphite, being a naturally occurring substance, presents an attractive option. Its use in energy storage solutions, particularly in lithium-ion batteries, aligns with the growing demand for renewable energy technologies. As the world moves towards cleaner energy sources, the demand for graphite powder is expected to rise, making it a critical material in the transition to sustainable practices.

Moreover, the production processes of graphite powder can vary, with methods such as grinding and milling being common. The quality and purity of graphite powder can significantly influence its performance in various applications. Therefore, choosing high-quality graphite powder is essential for industries that rely on its unique properties.

In conclusion, graphite powder serves as an essential material in various industries, particularly in metallurgy and energy sectors. Its unique properties, such as thermal and electrical conductivity, chemical inertness, and lubricating qualities, highlight its versatility and importance in modern manufacturing processes. As industries evolve towards sustainable practices, graphite powder will continue to play a crucial role in facilitating advancements across multiple sectors.

Previous:

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property