The Role of Petroleum Coke in Sustainable Manufacturing Processes

Summary:

The Role of Petroleum Coke in Sustainable Manufacturing Processes

Table of Contents

1. Understanding Petroleum Coke: A Brief Overview

2. The Production Process of Petroleum Coke

3. Key Characteristics of Petroleum Coke

4. Applications of Petroleum Coke in Manufacturing

4.1. Use in Energy Production

4.2. Role in Aluminum Production

4.3. Contribution to Cement Manufacturing

4.4. Ot

The Role of Petroleum Coke in Sustainable Manufacturing Processes

Table of Contents

1. Understanding Petroleum Coke: A Brief Overview

2. The Production Process of Petroleum Coke

3. Key Characteristics of Petroleum Coke

4. Applications of Petroleum Coke in Manufacturing

4.1. Use in Energy Production

4.2. Role in Aluminum Production

4.3. Contribution to Cement Manufacturing

4.4. Other Industrial Applications

5. Sustainability Aspects of Petroleum Coke

5.1. Carbon Footprint Considerations

5.2. Recycling and Reuse Opportunities

6. Challenges and Criticisms Surrounding Petroleum Coke

7. Future Trends in Petroleum Coke Usage

8. FAQs About Petroleum Coke and Sustainable Manufacturing

9. Conclusion

1. Understanding Petroleum Coke: A Brief Overview

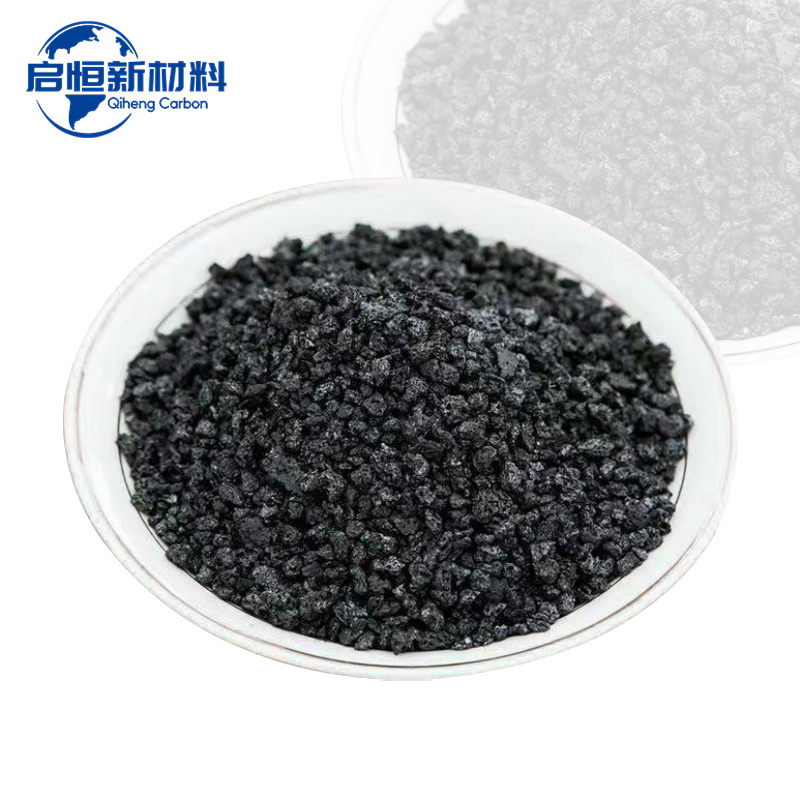

Petroleum coke, commonly referred to as petcoke, is a solid carbon material that is a byproduct of the oil refining process. As the demand for cleaner and more sustainable production methods rises, the relevance of petroleum coke in various manufacturing processes cannot be overstated. Its high carbon content and calorific value make it an attractive alternative for industries looking to enhance their sustainability efforts.

2. The Production Process of Petroleum Coke

The production of petroleum coke primarily occurs during the coking process in oil refineries, where heavy crude oil is subjected to high temperatures. This thermal decomposition process results in the conversion of heavy fractions of crude oil into lighter hydrocarbons and solid carbon. The final product, petroleum coke, can vary in its properties depending on the specific feedstock and production conditions, giving rise to different grades such as fuel-grade and anode-grade petcoke.

3. Key Characteristics of Petroleum Coke

Petroleum coke possesses several characteristics that make it invaluable in manufacturing. Its **high carbon content**, generally over 90%, ensures a high calorific value, making it an efficient fuel source. Additionally, its **low sulfur content** enhances its suitability for environmentally friendly operations. The structure of petcoke also allows it to function effectively in various applications, providing both thermal and chemical energy when utilized in different manufacturing processes.

4. Applications of Petroleum Coke in Manufacturing

Petroleum coke finds diverse applications across multiple industries, playing a significant role in sustainable manufacturing practices.

4.1. Use in Energy Production

In the energy sector, petroleum coke serves as a cost-effective **alternative fuel** for power generation. Its high calorific value makes it a preferred choice for coal-fired power plants looking to reduce emissions while maintaining energy efficiency. Additionally, petcoke can be blended with natural gas or coal to optimize combustion processes, leading to significant reductions in greenhouse gas emissions.

4.2. Role in Aluminum Production

In the **aluminum industry**, petroleum coke is primarily used to produce anodes for aluminum smelting. The high carbon content of petcoke provides the necessary conductivity for electrolysis processes, which are vital in aluminum production. By utilizing petroleum coke, aluminum manufacturers can achieve a lower carbon footprint, thus aligning with global sustainability goals.

4.3. Contribution to Cement Manufacturing

The **cement industry** benefits from petroleum coke as a supplementary fuel in kilns. Its high energy content helps in maintaining the required temperature for clinker production. Moreover, petcoke’s use in cement manufacturing reduces dependence on traditional fossil fuels, contributing to more sustainable production methods.

4.4. Other Industrial Applications

Beyond energy, aluminum, and cement, petroleum coke is also utilized in the production of **carbon black**, an essential ingredient in rubber manufacturing, and as a filler in various industrial applications. Its versatility ensures that it plays a crucial role in numerous manufacturing processes, all while promoting sustainability.

5. Sustainability Aspects of Petroleum Coke

The shift towards sustainable manufacturing practices necessitates a closer look at the environmental impact of materials used in production. Petroleum coke presents several sustainability advantages.

5.1. Carbon Footprint Considerations

One of the most significant sustainability benefits of using petroleum coke is its potential to lower the carbon footprint of manufacturing processes. Compared to other fossil fuels, petcoke produces less CO2 per unit of energy generated, making it an attractive option for industries aiming to reduce greenhouse gas emissions.

5.2. Recycling and Reuse Opportunities

Innovative recycling methods are emerging within industries that use petroleum coke. As manufacturers strive for circular economy principles, the potential for repurposing petcoke in various applications continues to grow. This not only minimizes waste but also enhances resource efficiency across the supply chain.

6. Challenges and Criticisms Surrounding Petroleum Coke

Despite its advantages, petroleum coke is not without controversy. Some **environmental concerns** arise due to the potential release of harmful pollutants during its combustion. Critics argue that while petcoke can contribute to sustainability, its production and use must be carefully managed to mitigate adverse environmental impacts. Striking a balance between leveraging petroleum coke's benefits and minimizing its negative effects remains a challenge for the industry.

7. Future Trends in Petroleum Coke Usage

As sustainability remains a priority for many industries, the role of petroleum coke is expected to evolve. Innovations in refining technology and carbon capture and storage (CCS) are likely to influence how petcoke is produced and utilized. Additionally, the growing emphasis on green manufacturing solutions will drive research into alternative uses for petroleum coke, enhancing its viability in sustainable production frameworks.

8. FAQs About Petroleum Coke and Sustainable Manufacturing

**Q1: What is petroleum coke?**

A1: Petroleum coke is a solid carbon material produced during the oil refining process, primarily through coking, which involves high-temperature thermal decomposition of heavy crude oil.

**Q2: How is petroleum coke used in sustainable manufacturing?**

A2: Petroleum coke is used as an alternative fuel in energy production, as anode material in aluminum production, and as a fuel source in cement manufacturing, contributing to lower carbon emissions and increased energy efficiency.

**Q3: What are the environmental impacts of petroleum coke?**

A3: The combustion of petroleum coke can release pollutants; however, it generally has a lower carbon footprint compared to traditional fossil fuels, making it a potential option for sustainable manufacturing when managed effectively.

**Q4: Are there recycling opportunities for petroleum coke?**

A4: Yes, industries are exploring various recycling methods for petroleum coke, which can be repurposed in multiple applications, promoting resource efficiency and minimizing waste.

**Q5: What future trends are expected in the use of petroleum coke?**

A5: Future trends may include advancements in refining technology, carbon capture and storage, and increased research into alternative uses for petroleum coke, enhancing its role in sustainable manufacturing.

9. Conclusion

In conclusion, petroleum coke stands at the intersection of traditional manufacturing and modern sustainability practices. Its characteristics and applications indicate a promising future for industries aiming to reduce their environmental impact while maintaining operational efficiency. As the world moves towards more sustainable manufacturing processes, the role of petroleum coke will undoubtedly evolve, presenting both challenges and opportunities. By embracing innovative practices and technologies, we can harness the potential of petroleum coke to drive a more sustainable future in manufacturing.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property