The Essential Guide to Graphite Blocks: Applications and Benefits in the Metallurgy Sector

Summary:

Graphite blocks are a vital component in the metallurgy and energy industries, particularly in the production and handling of non-metallic mineral products. Their unique physical and chemical properties make them indispensable in a range of applications. Composed primarily of carbon, graphite blocks exhibit high thermal conductivity, excellent electrical conductivity, and remarkable resistance to

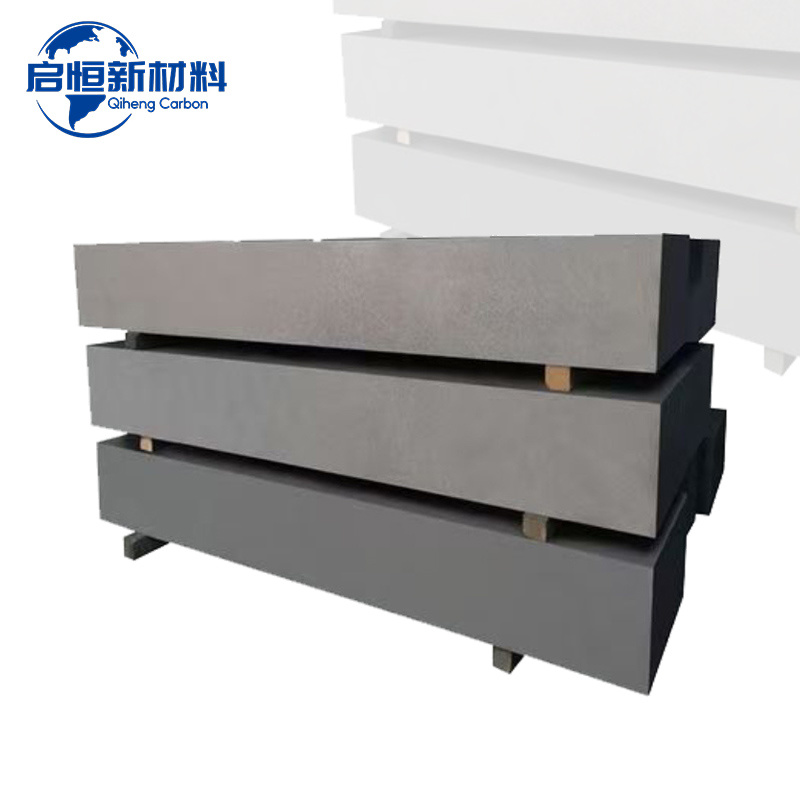

Graphite blocks are a vital component in the metallurgy and energy industries, particularly in the production and handling of non-metallic mineral products. Their unique physical and chemical properties make them indispensable in a range of applications. Composed primarily of carbon, graphite blocks exhibit high thermal conductivity, excellent electrical conductivity, and remarkable resistance to thermal shock, enabling their use in high-temperature environments.

One of the primary applications of graphite blocks is in the manufacturing of electrodes for electric arc furnaces. These electrodes are crucial for melting metals, and graphite's ability to conduct electricity efficiently makes it an ideal material. The durability and performance of graphite blocks significantly enhance the efficiency of the melting process, which is essential for industries such as steel production.

In addition to their use in electrodes, graphite blocks are also employed in various furnace linings and in the creation of crucibles. Their thermal resistance prevents damage during extreme heating and cooling cycles, ensuring that industrial processes can operate smoothly without interruptions or failures. Furthermore, graphite blocks can be machined into different shapes and sizes, providing versatility for specific industrial requirements.

Another significant benefit of graphite blocks is their chemical inertness. This property allows them to withstand various corrosive environments without deteriorating, making them suitable for applications in chemical processing. Their use in reactors and other high-temperature chemical applications underscores their importance in the non-metallic mineral products sector.

Graphite blocks also contribute to energy efficiency. Their high thermal conductivity allows for faster heat transfer, which can lead to reduced energy consumption during industrial processes. As industries increasingly focus on sustainability and efficiency, the role of graphite blocks becomes even more crucial. Utilizing these blocks can help companies not only improve their operational efficiency but also reduce their environmental footprint.

In summary, graphite blocks are essential materials within the metallurgy and energy sectors, providing benefits that range from high conductivity to chemical resistance. Their versatility and durability make them a preferred choice for a wide array of industrial applications. As the demand for efficient and sustainable manufacturing processes continues to grow, understanding the properties and uses of graphite blocks will be vital for professionals in these industries. Embracing this knowledge can lead to improved operational practices and enhanced productivity in metallurgy and energy applications.

One of the primary applications of graphite blocks is in the manufacturing of electrodes for electric arc furnaces. These electrodes are crucial for melting metals, and graphite's ability to conduct electricity efficiently makes it an ideal material. The durability and performance of graphite blocks significantly enhance the efficiency of the melting process, which is essential for industries such as steel production.

In addition to their use in electrodes, graphite blocks are also employed in various furnace linings and in the creation of crucibles. Their thermal resistance prevents damage during extreme heating and cooling cycles, ensuring that industrial processes can operate smoothly without interruptions or failures. Furthermore, graphite blocks can be machined into different shapes and sizes, providing versatility for specific industrial requirements.

Another significant benefit of graphite blocks is their chemical inertness. This property allows them to withstand various corrosive environments without deteriorating, making them suitable for applications in chemical processing. Their use in reactors and other high-temperature chemical applications underscores their importance in the non-metallic mineral products sector.

Graphite blocks also contribute to energy efficiency. Their high thermal conductivity allows for faster heat transfer, which can lead to reduced energy consumption during industrial processes. As industries increasingly focus on sustainability and efficiency, the role of graphite blocks becomes even more crucial. Utilizing these blocks can help companies not only improve their operational efficiency but also reduce their environmental footprint.

In summary, graphite blocks are essential materials within the metallurgy and energy sectors, providing benefits that range from high conductivity to chemical resistance. Their versatility and durability make them a preferred choice for a wide array of industrial applications. As the demand for efficient and sustainable manufacturing processes continues to grow, understanding the properties and uses of graphite blocks will be vital for professionals in these industries. Embracing this knowledge can lead to improved operational practices and enhanced productivity in metallurgy and energy applications.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property