Graphite Crucibles: Essential Guidelines for Safe Handling and Usage

Summary:

Graphite Crucibles: Essential Guidelines for Safe Handling and Usage

Table of Contents

1. Introduction to Graphite Crucibles

2. Understanding the Composition and Properties of Graphite

3. Why Graphite Crucibles Are Used in Metallurgy

4. Safety Considerations When Using Graphite Crucibles

4.1. Personal Protective Equipment (PPE)

4.2. Proper Handling Techniques

5. Maintenance and Care for Graphite C

Graphite Crucibles: Essential Guidelines for Safe Handling and Usage

Table of Contents

1. Introduction to Graphite Crucibles

2. Understanding the Composition and Properties of Graphite

3. Why Graphite Crucibles Are Used in Metallurgy

4. Safety Considerations When Using Graphite Crucibles

4.1. Personal Protective Equipment (PPE)

4.2. Proper Handling Techniques

5. Maintenance and Care for Graphite Crucibles

6. Best Practices for Storage of Graphite Crucibles

7. Common Applications of Graphite Crucibles

8. FAQs About Graphite Crucibles

9. Conclusion

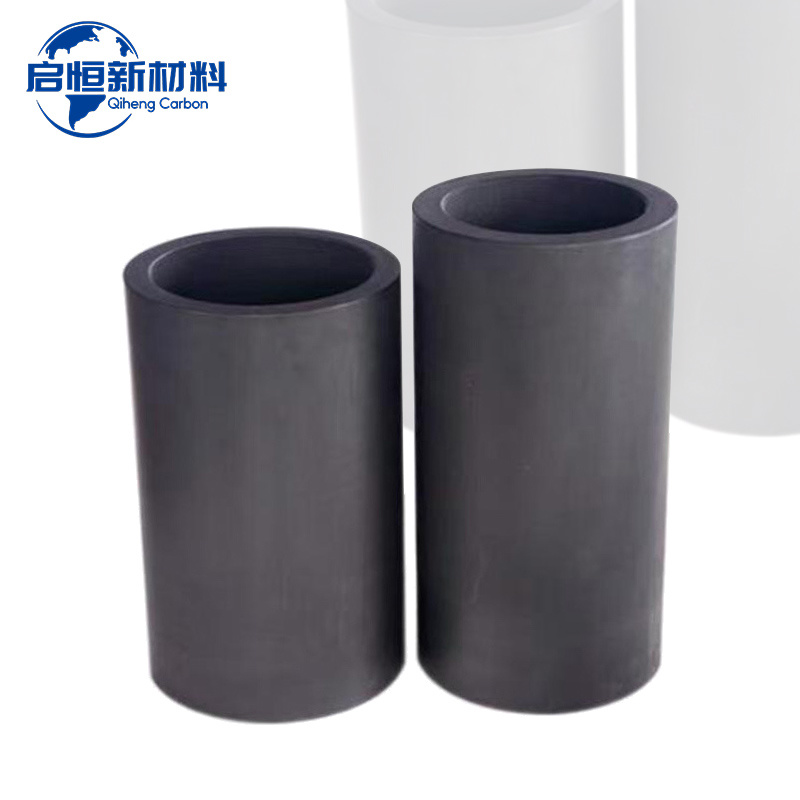

1. Introduction to Graphite Crucibles

Graphite crucibles are indispensable tools in various industries, particularly in metallurgy and the processing of non-metallic mineral products. These containers, made from high-purity graphite, are designed to withstand extreme temperatures and are crucial for melting and casting metals. Understanding how to safely handle and use these crucibles is essential for professionals who work in environments where molten metals and other high-temperature processes are common.

2. Understanding the Composition and Properties of Graphite

Graphite is a crystalline form of carbon known for its exceptional thermal conductivity, high-temperature resistance, and chemical stability. Graphite crucibles are engineered to take advantage of these properties, allowing them to resist thermal shock and maintain structural integrity under intense heat.

The purity of the graphite used in crucibles is critical, as impurities can affect the quality of the molten metal and potentially compromise the final product. High-purity graphite, often sourced from natural deposits, contributes to the durability and efficiency of crucibles.

3. Why Graphite Crucibles Are Used in Metallurgy

The choice of graphite crucibles in metallurgy stems from their unique ability to withstand high temperatures essential for melting various metals, including precious metals, aluminum, and iron. Their thermal conductivity ensures efficient heat transfer, which is vital for maintaining uniform temperatures during the melting process. Additionally, graphite is inert, meaning it does not react adversely with the metals being melted, which is crucial for preventing contamination of the molten material.

Graphite crucibles are also lightweight compared to other materials, facilitating ease of handling and transportation.

4. Safety Considerations When Using Graphite Crucibles

When working with graphite crucibles, safety should always be a priority. Here are key considerations to ensure a safe working environment.

4.1. Personal Protective Equipment (PPE)

Wearing appropriate personal protective equipment (PPE) is essential when handling graphite crucibles. This includes heat-resistant gloves, safety goggles, face shields, and protective clothing. PPE serves not only as a barrier against heat but also against the potential for chemical exposure and physical injuries.

4.2. Proper Handling Techniques

Proper handling techniques are critical to preventing accidents and injuries. Always use tongs or lifting tools designed for heavy objects when moving graphite crucibles. It’s important to ensure you have a stable grip and to avoid sudden movements that could lead to drops or spills.

Never attempt to handle a crucible that is still hot without appropriate tools. Allow sufficient time for cooling after use before attempting to move or clean the crucible.

5. Maintenance and Care for Graphite Crucibles

To prolong the life of graphite crucibles, proper maintenance and care are necessary. After each use, allow the crucibles to cool completely before cleaning. Use a soft brush to remove any residual materials, and avoid abrasive tools that could damage the surface.

Inspect crucibles regularly for signs of wear or damage. Cracked or otherwise compromised crucibles should be replaced immediately to avoid potential hazards during operation.

6. Best Practices for Storage of Graphite Crucibles

Correct storage of graphite crucibles is vital for maintaining their integrity and performance. Crucibles should be stored in a dry, temperature-controlled environment away from direct sunlight. Stack them carefully to prevent chipping or cracking. Label storage areas to ensure that the right crucibles are easily accessible and that they are stored in an organized manner.

7. Common Applications of Graphite Crucibles

Graphite crucibles find broad applications across various industries:

1. **Metallurgy**: Used for melting ferrous and non-ferrous metals, ensuring high-quality results.

2. **Jewelry Making**: Crucibles are essential for melting precious metals such as gold and silver.

3. **Laboratory Use**: In scientific laboratories, graphite crucibles are utilized for high-temperature experiments and materials testing.

4. **Casting**: Widely used in the casting of various materials where thermal stability is required.

8. FAQs About Graphite Crucibles

**Q1: What is the maximum temperature a graphite crucible can withstand?**

A1: Graphite crucibles can typically withstand temperatures up to 3000°C, depending on their composition.

**Q2: Can graphite crucibles be reused?**

A2: Yes, graphite crucibles can be reused multiple times; however, proper cleaning and maintenance are essential to prevent contamination.

**Q3: How do I know when to replace my graphite crucible?**

A3: Inspect your crucible regularly for cracks or significant wear. If you notice any damage, it’s best to replace it.

**Q4: Are graphite crucibles safe to handle?**

A4: While graphite crucibles are safe when handled correctly, it is imperative always to use PPE and follow safety guidelines.

**Q5: What are the advantages of using graphite crucibles over ceramic ones?**

A5: Graphite crucibles offer better thermal conductivity, higher resistance to thermal shock, and are generally lighter than ceramic crucibles.

9. Conclusion

Using graphite crucibles safely and efficiently is crucial for professionals in metallurgy and related industries. By understanding the properties of graphite, employing appropriate safety measures, and following best practices for maintenance and storage, we can ensure the longevity and effectiveness of these vital tools. With the right knowledge and precautions, we can optimize our operations while keeping safety at the forefront of our practices.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property