Unlocking the Secrets of Calcined Petroleum Coke: Essential Insights for the Chemical Industry

Summary:

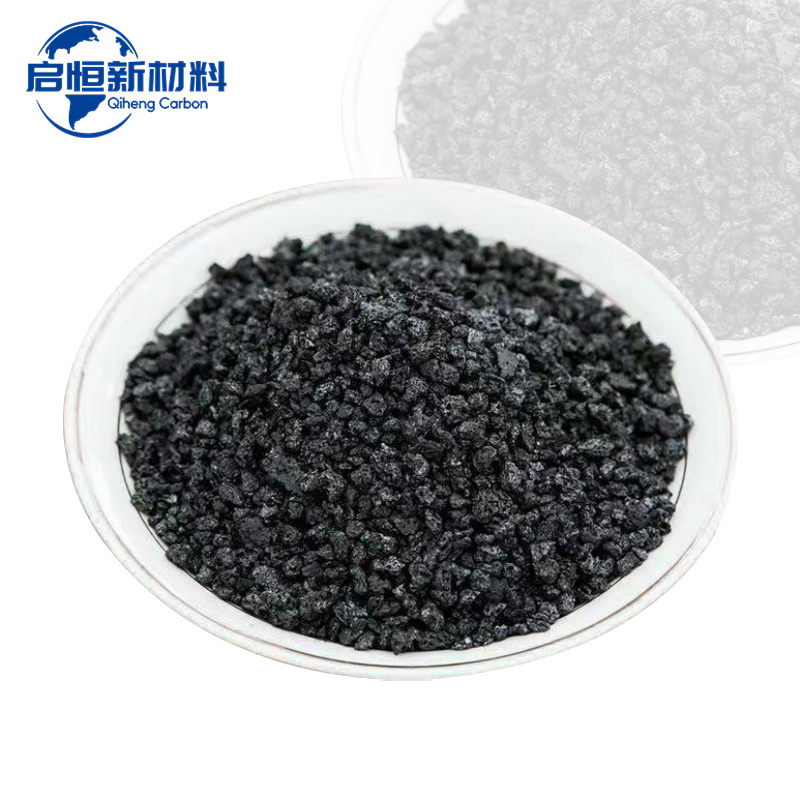

Calcined petroleum coke (CPC) is a critical material in the chemical industry, particularly in the production of aluminum, steel, and other industrial applications. Understanding its properties and production methods can significantly impact manufacturing processes and end-product quality.

Calcined petroleum coke is derived from the thermal treatment of green petroleum coke, which is produced duri

Calcined petroleum coke (CPC) is a critical material in the chemical industry, particularly in the production of aluminum, steel, and other industrial applications. Understanding its properties and production methods can significantly impact manufacturing processes and end-product quality.

Calcined petroleum coke is derived from the thermal treatment of green petroleum coke, which is produced during the oil refining process. The calcination process involves heating the green coke in a rotary kiln or furnace at temperatures exceeding 1200 degrees Celsius. This high-temperature treatment removes volatile substances, resulting in a denser and more carbon-rich material. The result is a product that boasts excellent electrical conductivity and low levels of impurities, making it ideal for various applications.

One of the primary uses of calcined petroleum coke is as an anode material in the aluminum smelting process. When used in aluminum electrolytic cells, CPC contributes to the production of aluminum by enabling the efficient electrolysis of aluminum oxide. This process requires high-quality anodes to ensure optimal performance, and the unique properties of calcined petroleum coke make it a preferred choice.

In addition to aluminum production, CPC finds applications in the manufacture of electrodes for the steel industry, as well as in the production of titanium dioxide and various carbon-based products. Its high carbon content and low sulfur levels make it a valuable material in these industries, where purity and conductivity are paramount.

The importance of calcined petroleum coke extends beyond its physical properties; it also plays a significant role in environmental sustainability. By utilizing CPC, industries can reduce their reliance on traditional carbon sources, leading to lower emissions and a smaller carbon footprint. This is increasingly crucial as companies strive to meet regulatory standards and consumer demand for greener practices.

When sourcing calcined petroleum coke, it is essential to consider factors such as the supply chain, quality control, and potential impurities that could affect end-product quality. Establishing relationships with reliable suppliers ensures consistent material quality and availability, which is vital for continuous production cycles.

In conclusion, calcined petroleum coke is an indispensable material in the chemical industry, particularly in the production of aluminum and steel. Its unique properties, production methods, and applications underscore its significance in modern manufacturing processes. Understanding the role of CPC not only enhances operational efficiency but also aligns with the industry's shift towards sustainable practices. By leveraging the advantages of calcined petroleum coke, businesses can optimize their processes and contribute to a greener future.

Calcined petroleum coke is derived from the thermal treatment of green petroleum coke, which is produced during the oil refining process. The calcination process involves heating the green coke in a rotary kiln or furnace at temperatures exceeding 1200 degrees Celsius. This high-temperature treatment removes volatile substances, resulting in a denser and more carbon-rich material. The result is a product that boasts excellent electrical conductivity and low levels of impurities, making it ideal for various applications.

One of the primary uses of calcined petroleum coke is as an anode material in the aluminum smelting process. When used in aluminum electrolytic cells, CPC contributes to the production of aluminum by enabling the efficient electrolysis of aluminum oxide. This process requires high-quality anodes to ensure optimal performance, and the unique properties of calcined petroleum coke make it a preferred choice.

In addition to aluminum production, CPC finds applications in the manufacture of electrodes for the steel industry, as well as in the production of titanium dioxide and various carbon-based products. Its high carbon content and low sulfur levels make it a valuable material in these industries, where purity and conductivity are paramount.

The importance of calcined petroleum coke extends beyond its physical properties; it also plays a significant role in environmental sustainability. By utilizing CPC, industries can reduce their reliance on traditional carbon sources, leading to lower emissions and a smaller carbon footprint. This is increasingly crucial as companies strive to meet regulatory standards and consumer demand for greener practices.

When sourcing calcined petroleum coke, it is essential to consider factors such as the supply chain, quality control, and potential impurities that could affect end-product quality. Establishing relationships with reliable suppliers ensures consistent material quality and availability, which is vital for continuous production cycles.

In conclusion, calcined petroleum coke is an indispensable material in the chemical industry, particularly in the production of aluminum and steel. Its unique properties, production methods, and applications underscore its significance in modern manufacturing processes. Understanding the role of CPC not only enhances operational efficiency but also aligns with the industry's shift towards sustainable practices. By leveraging the advantages of calcined petroleum coke, businesses can optimize their processes and contribute to a greener future.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property