How to Select the Right Graphite Electrode Based on Application: A Comprehensive Guide

Summary:

How to Select the Right Graphite Electrode Based on Application

Table of Contents

1. Introduction: The Importance of Graphite Electrodes

2. Types of Graphite Electrodes: An Overview

3. Key Factors in Selecting Graphite Electrodes

3.1 Application-Specific Requirements

3.2 Conductivity and Performance

3.3 Thermal Resistance and Stability

3.4 Si

How to Select the Right Graphite Electrode Based on Application

Table of Contents

- 1. Introduction: The Importance of Graphite Electrodes

- 2. Types of Graphite Electrodes: An Overview

- 3. Key Factors in Selecting Graphite Electrodes

- 3.1 Application-Specific Requirements

- 3.2 Conductivity and Performance

- 3.3 Thermal Resistance and Stability

- 3.4 Size and Shape Considerations

- 4. Leading Graphite Electrode Manufacturers

- 5. Application Scenarios: Best Practices in Selection

- 6. Maintaining and Replacing Graphite Electrodes

- 7. Frequently Asked Questions (FAQs)

- 8. Conclusion

1. Introduction: The Importance of Graphite Electrodes

Graphite electrodes play a pivotal role in the metallurgical and energy industries, particularly in electric arc furnaces (EAF) and other high-temperature applications. As the backbone of these processes, selecting the right graphite electrode is crucial for optimal performance and cost-effectiveness. This article delves into the various factors that influence the selection of graphite electrodes based on specific applications, ensuring that you understand how to choose the best option for your needs.

2. Types of Graphite Electrodes: An Overview

Understanding the different types of graphite electrodes is fundamental to selecting the right one for your application. The primary types include:

2.1 Regular Power (RP) Graphite Electrodes

Regular power electrodes are commonly used for general applications where a standard level of performance is sufficient. They are suitable for most melting and processing tasks, providing a balance between cost and functionality.

2.2 High Power (HP) Graphite Electrodes

High power electrodes are designed for enhanced performance in demanding applications. They feature a higher density and improved electrical conductivity, making them ideal for high-temperature operations such as steelmaking.

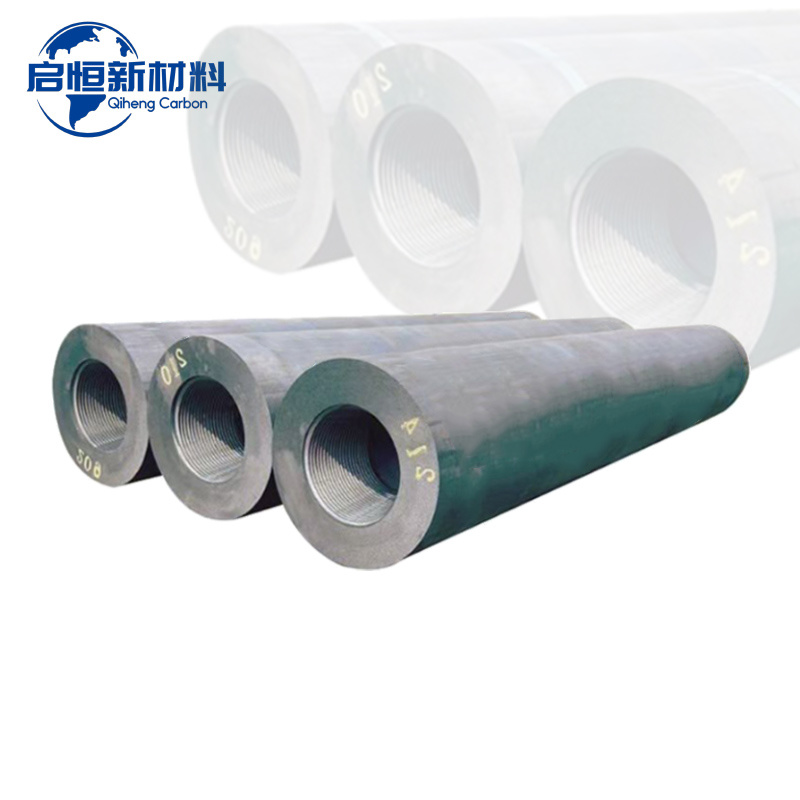

2.3 Ultra High Power (UHP) Graphite Electrodes

Ultra high power electrodes are tailored for extreme conditions and high energy requirements. With superior thermal resistance and conductivity, they are essential for processes requiring maximum efficiency and minimal downtime.

3. Key Factors in Selecting Graphite Electrodes

Choosing the right graphite electrode involves considering several key factors that can directly impact performance and cost.

3.1 Application-Specific Requirements

Evaluate the specific needs of your application, including the type of material being processed, the operational environment, and the desired end products. Different processes, such as melting ferrous vs. non-ferrous metals, will require different electrode specifications.

3.2 Conductivity and Performance

The electrical conductivity of graphite electrodes is a critical factor influencing their performance. Higher conductivity results in lower energy consumption and reduced operational costs. When selecting electrodes, look for those with a conductivity rating that matches your application’s requirements.

3.3 Thermal Resistance and Stability

Graphite electrodes must withstand extreme temperatures without degrading. Assess the thermal resistance of potential electrodes, focusing on their ability to maintain structural integrity under prolonged exposure to high heat.

3.4 Size and Shape Considerations

The dimensions and shape of graphite electrodes are vital for ensuring compatibility with your equipment. Standard sizes are available, but custom dimensions may be necessary based on your specific furnace or processing setup.

4. Leading Graphite Electrode Manufacturers

Selecting a reliable manufacturer is key to acquiring high-quality graphite electrodes. Look for manufacturers with a proven track record in the industry, offering certifications and adhering to quality standards. Some of the leading manufacturers include:

- **GrafTech International**

- **SGL Carbon**

- **Tokai Carbon**

- **Mersen**

- **Showa Denko**

Research each manufacturer’s product specifications and customer reviews to ensure that they can meet your needs effectively.

5. Application Scenarios: Best Practices in Selection

Different applications will dictate different selection criteria. Here are some common scenarios and best practices for electrode selection:

5.1 Electric Arc Furnace Applications

In EAF applications, consider high power or ultra high power electrodes to achieve the necessary temperatures and energy efficiency. Ensure that the electrodes can withstand the repeated cycling of heating and cooling during operations.

5.2 Foundry Operations

For foundry applications, regular power electrodes may suffice, but assessing the specific metal and alloy types being cast is essential. Choose electrodes that provide sufficient conductivity and thermal stability for the materials involved.

5.3 Recycling and Secondary Steelmaking

In recycling processes, durability and resistance to abrasion are paramount. Selecting electrodes with high thermal shock resistance can enhance performance and minimize wear and tear.

6. Maintaining and Replacing Graphite Electrodes

Proper maintenance of graphite electrodes can extend their lifespan and improve operational efficiency. Here are some tips:

- **Regular Inspection**: Conduct routine inspections for signs of wear, cracking, or degradation.

- **Proper Handling**: Handle electrodes carefully to avoid physical damage.

- **Replacement Timeliness**: Replace electrodes before they reach the end of their lifespan to prevent process interruptions.

By prioritizing maintenance, you can enhance electrode performance and reduce overall costs.

7. Frequently Asked Questions (FAQs)

7.1 What is the primary function of graphite electrodes?

Graphite electrodes are primarily used to conduct electrical current in high-temperature applications, such as electric arc furnaces and other metallurgical processes.

7.2 How do I know which type of graphite electrode to choose?

Consider your application requirements, including temperature, material type, and energy efficiency needs. Evaluate the properties of each electrode type to make an informed decision.

7.3 What are the key advantages of high power and ultra high power electrodes?

High power and ultra high power electrodes offer enhanced electrical conductivity, greater thermal resistance, and improved performance under extreme conditions, making them suitable for demanding applications.

7.4 How often should I replace graphite electrodes?

Replacement frequency depends on usage, wear, and specific operational conditions. Regular inspections can help determine the right timing for replacement.

7.5 Can I use a regular power electrode for high-temperature applications?

While regular power electrodes may function at elevated temperatures, their performance may not match that of high power or ultra high power electrodes under extreme conditions.

8. Conclusion

Selecting the right graphite electrode based on application is a multifaceted process that requires careful consideration of various factors, including conductivity, thermal resistance, and application-specific requirements. By understanding the types of electrodes available and their respective advantages, you can make informed decisions that will enhance operational efficiency and reduce costs. Prioritizing quality and reliability in both electrode selection and manufacturer choice will ultimately lead to improved performance in your metallurgical and energy processes.

Previous:

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property