How to Select the Best UHP Graphite Electrode for Your Application: A Comprehensive Guide

Summary:

How to Select the Best UHP Graphite Electrode for Your Application

Table of Contents

1. Introduction to UHP Graphite Electrodes

2. What Are UHP Graphite Electrodes?

3. Applications of UHP Graphite Electrodes in Industries

4. Important Factors in Selecting UHP Graphite Electrodes

4.1 Material Quality

4.2 Electrode Diameter and Length

4.3 Thermal Conductivity

4.

How to Select the Best UHP Graphite Electrode for Your Application

Table of Contents

- 1. Introduction to UHP Graphite Electrodes

- 2. What Are UHP Graphite Electrodes?

- 3. Applications of UHP Graphite Electrodes in Industries

- 4. Important Factors in Selecting UHP Graphite Electrodes

- 4.1 Material Quality

- 4.2 Electrode Diameter and Length

- 4.3 Thermal Conductivity

- 4.4 Electrical Conductivity

- 4.5 Mechanical Strength

- 5. Performance Considerations for UHP Graphite Electrodes

- 6. Evaluating Suppliers of UHP Graphite Electrodes

- 7. Common Mistakes to Avoid When Selecting UHP Graphite Electrodes

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to UHP Graphite Electrodes

In industrial applications, the selection of the right materials is crucial for ensuring optimal performance and efficiency. Among these materials, **Ultra High Power (UHP) graphite electrodes** play a vital role in various sectors, especially in electric arc furnaces (EAF) and other high-temperature processes. Understanding the nuances of these electrodes can significantly impact the overall productivity and cost-effectiveness of operations. This guide aims to provide a thorough understanding of how to select the best UHP graphite electrode for your specific requirements.

2. What Are UHP Graphite Electrodes?

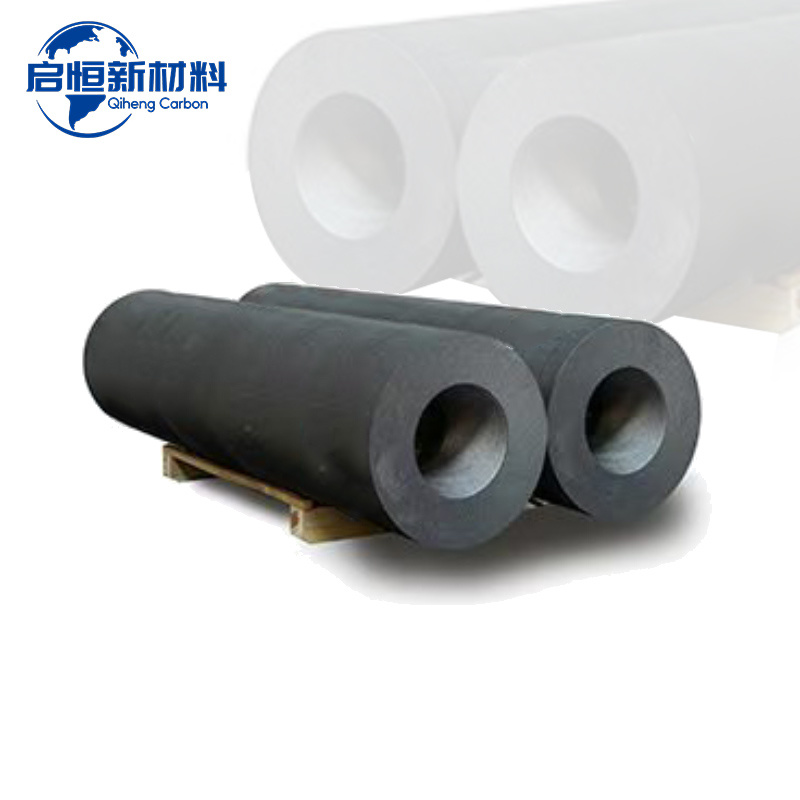

**UHP graphite electrodes** are specially designed for use in high-power applications, characterized by their superior thermal and electrical conductivity. These electrodes are primarily made from high-quality petroleum needle coke, which undergoes a series of processes to achieve their unique properties. UHP graphite electrodes are crucial for industries that require high performance and reliability in extreme conditions.

3. Applications of UHP Graphite Electrodes in Industries

UHP graphite electrodes find extensive applications across various industries, including:

3.1 Steel Production

In steelmaking, UHP graphite electrodes are indispensable for electric arc furnaces, enabling the melting of scrap metal and the production of high-quality steel.

3.2 Aluminum Production

In the aluminum industry, these electrodes are used in smelting processes, helping to facilitate the electrolysis of alumina.

3.3 Foundries

UHP graphite electrodes are also utilized in foundries for casting applications, where consistent performance is paramount.

3.4 Chemical Industries

In chemical manufacturing, these electrodes are employed in various processes that require high temperatures and electrical conductivity.

4. Important Factors in Selecting UHP Graphite Electrodes

When selecting UHP graphite electrodes, several critical factors must be taken into account to ensure optimal performance and cost-efficiency.

4.1 Material Quality

The quality of the material used in manufacturing UHP graphite electrodes significantly influences their performance. High-quality petroleum needle coke should be the primary raw material, as it provides better thermal and electrical conductivity. Analyzing the material composition and purity is essential for guaranteeing electrode effectiveness.

4.2 Electrode Diameter and Length

Electrode dimensions, including diameter and length, directly affect the performance in different applications. Selecting the right size ensures adequate electrical current flow and heat distribution, ultimately influencing melting efficiency and energy consumption.

4.3 Thermal Conductivity

Thermal conductivity is a critical factor in the selection of UHP graphite electrodes. High thermal conductivity allows for rapid heat transfer, enhancing the efficiency of the melting process. It is essential to choose electrodes with optimal thermal conductivity for your specific application.

4.4 Electrical Conductivity

Similar to thermal conductivity, electrical conductivity is paramount for UHP graphite electrodes. The ability to conduct electricity efficiently ensures minimal energy loss and enhances overall performance in high-temperature applications.

4.5 Mechanical Strength

Mechanical strength is essential for electrode durability, especially under extreme conditions. Ensuring that the electrodes can withstand mechanical stress during operation reduces the risk of breakage and extends their service life.

5. Performance Considerations for UHP Graphite Electrodes

Apart from material properties, several performance considerations play a role in the effective operation of UHP graphite electrodes.

5.1 Temperature Resistance

High-quality UHP graphite electrodes should exhibit excellent temperature resistance to sustain the demanding conditions of electric arc furnaces. Proper evaluation of temperature thresholds is necessary to avoid premature wear.

5.2 Erosion Resistance

Erosion resistance is crucial for electrodes used in environments with high electromagnetic forces and thermal gradients. Selecting electrodes with superior erosion resistance can significantly enhance their longevity and performance.

5.3 Thermal Shock Resistance

Electrodes should also possess adequate thermal shock resistance to withstand rapid temperature changes. This property protects against micro-cracking and structural failure during operation.

6. Evaluating Suppliers of UHP Graphite Electrodes

Choosing the right supplier is equally important as selecting the electrodes themselves. When evaluating suppliers, consider the following criteria:

6.1 Reputation and Experience

A supplier with a proven track record and extensive experience in the industry is more likely to provide high-quality UHP graphite electrodes.

6.2 Quality Assurance

Ensure that the supplier adheres to strict quality control measures and provides certifications for their products. This guarantees that you receive electrodes that meet industry standards.

6.3 Customer Service

Effective communication and customer service can enhance your buying experience. A responsive supplier who understands your needs can provide valuable recommendations tailored to your specific application.

7. Common Mistakes to Avoid When Selecting UHP Graphite Electrodes

To ensure you make the best decision, be aware of common mistakes:

7.1 Underestimating Application Requirements

Failing to thoroughly understand the specific requirements of your application can lead to selecting inappropriate electrodes. Always assess your needs before making a decision.

7.2 Ignoring Supplier Reputation

Choosing a supplier based solely on price can result in poor-quality products. Prioritize reputation and quality assurance over cost when selecting a supplier.

7.3 Neglecting Maintenance Considerations

Overlooking maintenance requirements can result in increased downtime and costs. Ensure you are aware of any specific maintenance needs associated with the electrodes you choose.

8. Frequently Asked Questions

8.1 What is the difference between UHP and HP graphite electrodes?

UHP graphite electrodes have higher thermal and electrical conductivity compared to HP (High Power) graphite electrodes, making them suitable for more demanding applications.

8.2 How do I determine the right diameter for my application?

The correct diameter depends on the furnace size and the type of operation. Consult with your supplier or conduct trials to identify the optimal diameter for your specific needs.

8.3 Can UHP graphite electrodes be recycled?

Yes, UHP graphite electrodes can be recycled, which reduces waste and is environmentally friendly. Discuss recycling options with your supplier.

8.4 How do I maintain UHP graphite electrodes?

Regular inspection and maintenance are essential. Follow manufacturer guidelines for cleaning and storage to ensure the longevity of the electrodes.

8.5 What is the average lifespan of UHP graphite electrodes?

The lifespan varies based on application and operating conditions but can range from several weeks to months with proper care and usage.

9. Conclusion

Choosing the right UHP graphite electrode for your application is a crucial decision that can significantly impact your operational efficiency and costs. By understanding the various factors such as material quality, dimensions, thermal and electrical conductivity, and supplier reputation, you can make an informed choice. Avoid common mistakes, and prioritize your application requirements to ensure optimal performance. With this comprehensive guide, you are now equipped with the knowledge to select the best UHP graphite electrode tailored to your specific needs, paving the way for enhanced productivity and reliability in your operations.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property