The Importance of Quality Control in UHP Graphite Electrode Production: Ensuring Excellence in Performance and Reliability

Summary:

The Importance of Quality Control in UHP Graphite Electrode Production

Table of Contents

Introduction to UHP Graphite Electrodes

What Are UHP Graphite Electrodes?

The Significance of Quality Control in Production

Quality Control Methodologies in UHP Graphite Electrode Production

Challenges in Maintaining Quality Control

The Impact of Quality on Performance and Reliability

The Importance of Quality Control in UHP Graphite Electrode Production

Table of Contents

- Introduction to UHP Graphite Electrodes

- What Are UHP Graphite Electrodes?

- The Significance of Quality Control in Production

- Quality Control Methodologies in UHP Graphite Electrode Production

- Challenges in Maintaining Quality Control

- The Impact of Quality on Performance and Reliability

- Best Practices for Effective Quality Control

- Conclusion

- FAQs about UHP Graphite Electrodes and Quality Control

Introduction to UHP Graphite Electrodes

UHP graphite electrodes are integral components in the electric arc furnaces (EAFs) used for steel production and other metallurgical applications. Their ability to withstand extreme temperatures and conduct electricity efficiently makes them indispensable in modern metallurgy. Given their critical role, the production of these electrodes requires stringent quality control measures to ensure they meet the demanding specifications of the industry.

What Are UHP Graphite Electrodes?

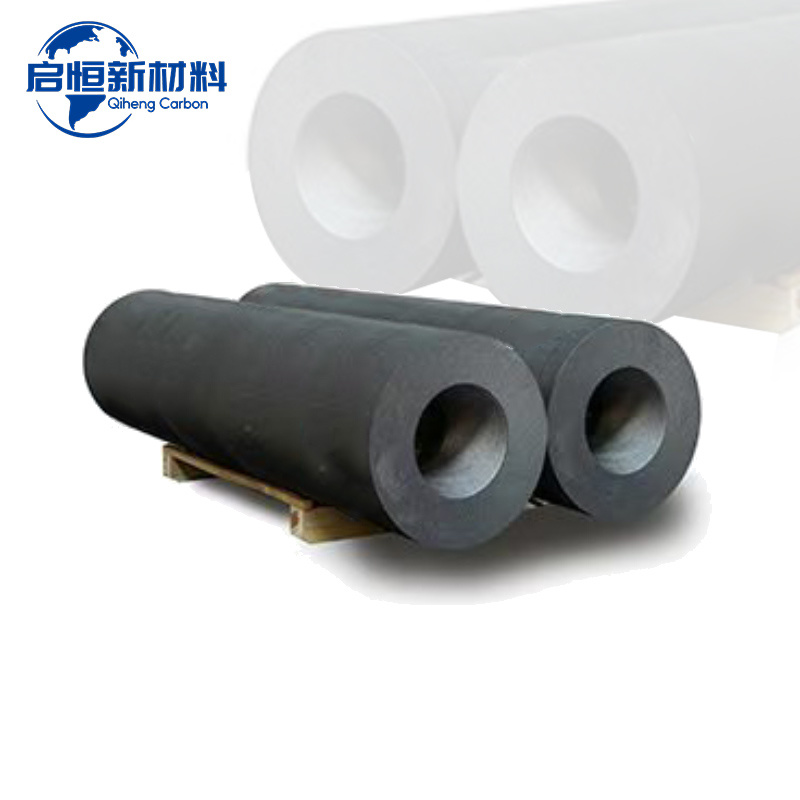

UHP graphite electrodes are specially manufactured electrodes designed for high-performance applications. These electrodes are composed primarily of high-quality petroleum needle coke and are subjected to high temperatures during the production process. The combination of their unique properties, such as low resistivity, high thermal conductivity, and exceptional mechanical strength, allows UHP graphite electrodes to perform effectively in harsh operational environments.

Key Characteristics of UHP Graphite Electrodes

1. **High Thermal Conductivity:** UHP graphite electrodes facilitate efficient heat transfer, vital for the melting process in electric arc furnaces.

2. **Low Electrical Resistivity:** This property ensures minimal energy loss, contributing to cost-effective operations.

3. **Mechanical Strength:** UHP electrodes must maintain structural integrity under extreme heat and mechanical stress.

4. **Chemical Resistance:** These electrodes are designed to withstand various chemical reactions that occur during metallurgical processes.

The Significance of Quality Control in Production

Quality control in UHP graphite electrode production is paramount for several reasons. It ensures that the electrodes meet industry standards and customer expectations while mitigating risks associated with performance failures. Poor quality can lead to increased operational costs, production downtime, and even safety hazards.

Ensuring Compliance with Industry Standards

Manufacturers must adhere to various international standards, including ISO certifications and specific industry regulations. Quality control processes are crucial for verifying compliance and maintaining certifications.

Enhancing Product Reliability

Reliable products lead to fewer failures in the field, reducing the frequency of replacements and enhancing customer satisfaction. Quality control measures help identify potential defects before the electrodes reach the end-user.

Quality Control Methodologies in UHP Graphite Electrode Production

Implementing effective quality control methodologies is essential for ensuring the production of high-quality UHP graphite electrodes. Here are some of the most widely used methods in the industry.

1. Incoming Material Inspection

Quality control begins with the raw materials. Inspecting and testing incoming petroleum needle coke and other materials is vital in identifying quality issues early in the production process.

2. In-Process Quality Control

Continuous monitoring during the manufacturing stages helps detect deviations from desired specifications. Techniques such as process control charts and statistical process control (SPC) are commonly employed to ensure consistency.

3. Final Product Testing

Once the manufacturing process is complete, rigorous testing of the final product is essential. This includes assessments of electrical conductivity, thermal properties, and mechanical strength, ensuring that each electrode meets predefined standards.

4. Traceability and Documentation

Maintaining detailed records of every step in the production process provides traceability. This documentation is crucial for identifying defects and implementing corrective actions promptly.

Challenges in Maintaining Quality Control

While the importance of quality control in UHP graphite electrode production is undeniable, several challenges can impede the process.

1. Variability in Raw Materials

Inconsistent quality of raw materials can lead to variability in the final product. Establishing strong supplier relationships and rigorous material testing protocols can mitigate this challenge.

2. Complex Manufacturing Processes

The manufacturing of UHP graphite electrodes involves multiple stages, each with its own set of variables. Ensuring quality across all stages requires comprehensive training and skilled personnel.

3. Evolving Industry Standards

As technology advances, industry standards continue to evolve. Staying abreast of these changes and adapting quality control processes accordingly is vital for maintaining competitiveness.

The Impact of Quality on Performance and Reliability

The quality of UHP graphite electrodes directly influences their performance in electric arc furnaces. High-quality electrodes result in improved melting efficiency, reduced energy consumption, and lower operational costs.

1. Increased Operational Efficiency

Electrodes manufactured with stringent quality control measures operate more efficiently, leading to reduced energy costs and higher productivity.

2. Decreased Downtime

Reliable electrodes minimize the risk of failures during operation, resulting in less downtime and more consistent production schedules.

3. Enhanced Customer Satisfaction

When customers receive high-quality products that perform consistently well, their overall satisfaction increases, leading to long-term relationships and repeat business.

Best Practices for Effective Quality Control

To ensure the highest standards in UHP graphite electrode production, companies should adopt the following best practices:

1. Implement a Comprehensive Quality Management System

A robust quality management system (QMS) encompassing all aspects of production will help streamline processes and ensure compliance with industry standards.

2. Train and Empower Employees

Investing in employee training and empowering them to take ownership of quality control leads to a more engaged workforce and better quality outcomes.

3. Utilize Modern Technology and Equipment

Leveraging advanced technologies such as automation, artificial intelligence, and data analytics can enhance monitoring and improve the overall quality control process.

4. Foster a Quality-Centric Culture

Creating an organizational culture that prioritizes quality at every level encourages employees to take quality seriously and continuously seek improvement.

Conclusion

Quality control in UHP graphite electrode production is not merely a regulatory necessity—it is a fundamental aspect that drives business success. By implementing effective quality control methodologies, addressing challenges, and adopting best practices, manufacturers can ensure the production of high-quality electrodes that meet the demanding requirements of the metallurgy and energy sectors. Ultimately, prioritizing quality leads to enhanced performance, increased reliability, and greater customer satisfaction, establishing a strong foundation for long-term success.

FAQs about UHP Graphite Electrodes and Quality Control

1. What are UHP graphite electrodes used for?

UHP graphite electrodes are primarily used in electric arc furnaces for steel production and other metallurgical processes due to their excellent thermal and electrical conductivity.

2. How is quality control implemented in UHP graphite electrode production?

Quality control is implemented through various methodologies, including incoming material inspection, in-process monitoring, final product testing, and comprehensive documentation.

3. Why is quality control important for UHP graphite electrodes?

Quality control is vital as it ensures compliance with industry standards, enhances product reliability, reduces operational costs, and improves customer satisfaction.

4. What challenges do manufacturers face in maintaining quality control?

Manufacturers face challenges such as variability in raw materials, complex manufacturing processes, and evolving industry standards that can affect the quality of the final product.

5. What are the best practices for ensuring quality in production?

Best practices include implementing a comprehensive quality management system, training employees, utilizing modern technology, and fostering a quality-centric culture within the organization.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property