How Graphite Crucibles Are Tested for Quality Assurance: Ensuring Optimal Performance

Summary:

How Graphite Crucibles Are Tested for Quality Assurance: Ensuring Optimal Performance

Table of Contents

1. Introduction to Graphite Crucibles

2. The Importance of Quality Assurance in Graphite Crucibles

3. Common Testing Methods for Graphite Crucibles

3.1 Visual Inspection

3.2 Dimensional Analysis

3.3 Density Testing

3.4 Thermal

How Graphite Crucibles Are Tested for Quality Assurance: Ensuring Optimal Performance

Table of Contents

- 1. Introduction to Graphite Crucibles

- 2. The Importance of Quality Assurance in Graphite Crucibles

- 3. Common Testing Methods for Graphite Crucibles

- 3.1 Visual Inspection

- 3.2 Dimensional Analysis

- 3.3 Density Testing

- 3.4 Thermal Conductivity Tests

- 3.5 Melt Ability Tests

- 4. Industry Standards and Regulations

- 5. The Role of Technology in Quality Assurance

- 6. The Future of Quality Testing for Graphite Crucibles

- 7. Conclusion

- 8. Frequently Asked Questions

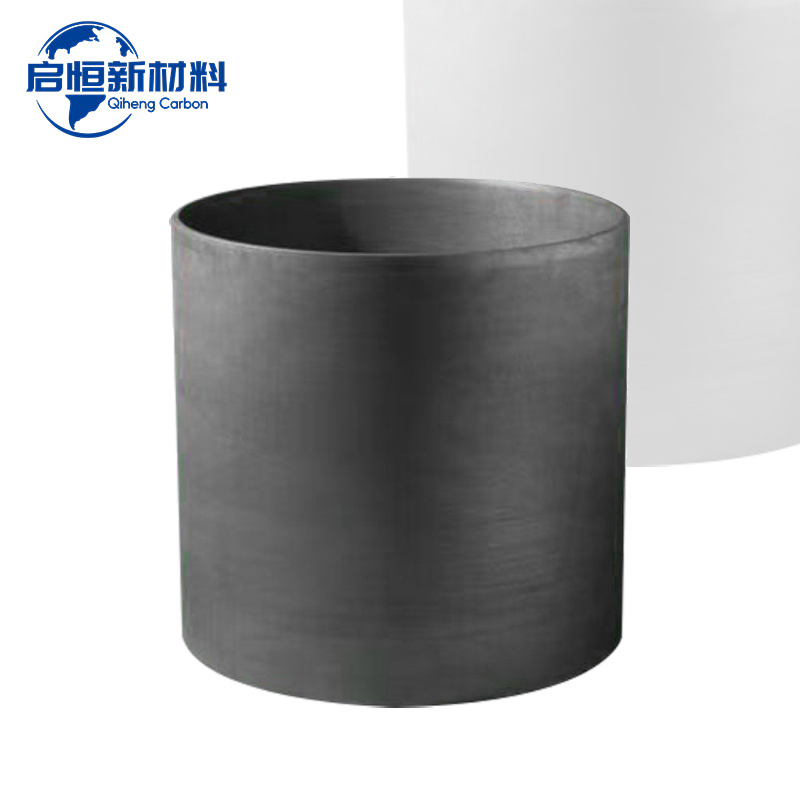

1. Introduction to Graphite Crucibles

Graphite crucibles play a pivotal role in various industrial processes, particularly in metallurgy and materials science. These containers are designed to withstand extreme temperatures and are critical for the melting and casting of metals and alloys. As such, ensuring their quality is not merely a preference but a necessity. Quality assurance in graphite crucibles involves a meticulous testing regimen to ascertain their performance under operational conditions.

2. The Importance of Quality Assurance in Graphite Crucibles

The significance of quality assurance in graphite crucibles cannot be overstated. Faulty crucibles can lead to catastrophic failures during metal casting, resulting in financial losses and potential safety hazards. Quality assurance ensures that each crucible meets specific standards for durability, heat resistance, and performance efficiency. By adhering to rigorous testing protocols, manufacturers can minimize the risks associated with poor-quality products and promote reliability in their applications.

3. Common Testing Methods for Graphite Crucibles

To ensure the integrity of graphite crucibles, several testing methodologies are employed. Each method serves a unique purpose and evaluates different aspects of the crucible's performance.

3.1 Visual Inspection

Visual inspection is often the first step in quality assurance. It involves checking for any obvious defects, such as cracks, chips, or surface irregularities. This method helps identify potential issues early in the manufacturing process, allowing for corrective actions before further testing.

3.2 Dimensional Analysis

Dimensional analysis focuses on measuring the physical dimensions of the crucibles to ensure they meet specified tolerances. Using precision measuring tools, manufacturers assess factors such as diameter, height, and wall thickness. Accurate dimensions are critical for proper fitting in melting furnaces and achieving optimal thermal performance.

3.3 Density Testing

Density testing involves determining the mass of the crucible relative to its volume. This test is crucial as it provides insights into the crucible's structural integrity and material composition. A higher density may indicate better quality, as it typically correlates with improved thermal conductivity and durability.

3.4 Thermal Conductivity Tests

Thermal conductivity testing evaluates how well the crucible can conduct heat, a vital characteristic for efficient melting processes. This test often employs advanced techniques such as laser flash analysis to measure the rate of heat transfer through the material. High thermal conductivity ensures that the crucible can handle the intense heat generated during metal melting.

3.5 Melt Ability Tests

Melt ability tests are designed to evaluate how well a graphite crucible performs when subjected to actual melting conditions. This testing typically involves heating the crucible with specific metals to assess its performance, including its resistance to thermal shock and potential chemical interactions with the molten metal.

4. Industry Standards and Regulations

Quality assurance in graphite crucibles is also governed by various industry standards and regulations. These guidelines establish the benchmarks for testing methodologies and performance criteria. Compliance with standards such as ASTM (American Society for Testing and Materials) and ISO certifications ensures that manufacturers produce crucibles that meet global quality expectations.

Manufacturers must remain updated with the latest standards and continuously adapt their testing protocols to align with any changes in regulations. This vigilance not only enhances product reliability but also builds trust with customers and stakeholders in the industry.

5. The Role of Technology in Quality Assurance

Advancements in technology have revolutionized the quality assurance processes for graphite crucibles. Modern testing equipment allows for more accurate and efficient assessments, reducing the chances of human error. Technologies such as computer modeling and simulation can predict how crucibles will perform under different operating conditions, leading to more informed design improvements.

Moreover, automation in testing processes has accelerated the speed at which quality assurance tasks can be completed. As a result, manufacturers can bring products to market faster without compromising on quality.

6. The Future of Quality Testing for Graphite Crucibles

Looking ahead, the future of quality testing for graphite crucibles is likely to be shaped by ongoing innovations in material science and manufacturing techniques. Increased emphasis on sustainability may lead to the development of eco-friendly graphite materials that still meet rigorous performance standards.

Furthermore, integrating artificial intelligence and machine learning into testing protocols could enhance predictive analytics, allowing manufacturers to anticipate potential failures and optimize production processes proactively.

The industry will continue to evolve, and staying abreast of technological advancements will be essential for maintaining competitive advantages in the market.

7. Conclusion

In conclusion, the testing of graphite crucibles for quality assurance is a multifaceted process that involves various methodologies aimed at ensuring optimal performance and reliability. From visual inspections to advanced thermal conductivity tests, each step plays a crucial role in guaranteeing that crucibles can withstand the demanding conditions of metal melting and casting.

As the industry continues to grow and evolve, the importance of stringent quality control measures remains paramount. By adhering to established standards and embracing technological advancements, manufacturers can ensure the production of high-quality graphite crucibles that meet the needs of their users while minimizing risks and enhancing operational efficiency.

8. Frequently Asked Questions

Q1: What materials are graphite crucibles made from?

A1: Graphite crucibles are primarily made from high-purity graphite, which provides excellent thermal conductivity and resistance to thermal shock. Some may also contain additives to enhance specific properties.

Q2: How long do graphite crucibles last?

A2: The lifespan of a graphite crucible can vary depending on the application, temperature, and frequency of use, but typically, they can last anywhere from 10 to 50 melts.

Q3: Can graphite crucibles be reused?

A3: Yes, graphite crucibles can often be reused, but their longevity depends on the materials melted and the conditions they are subjected to. Proper care and maintenance can extend their life.

Q4: What happens if a graphite crucible fails during use?

A4: If a graphite crucible fails during use, it can lead to contamination of the molten metal, production delays, and safety hazards. Therefore, regular quality assurance testing is essential to prevent such incidents.

Q5: Are there alternatives to graphite crucibles?

A5: Yes, alternatives include ceramic and metal crucibles. However, graphite crucibles are favored for many applications due to their excellent thermal properties and resistance to chemical corrosion.

This comprehensive exploration of how graphite crucibles are tested for quality assurance underscores the vital role these components play in industrial applications. By understanding the rigorous testing processes and advancements in technology, stakeholders can ensure the reliability and performance of graphite crucibles in their operations.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property