Understanding Calcined Petroleum Coke: An Essential Component in the Petrochemical Industry

Summary:

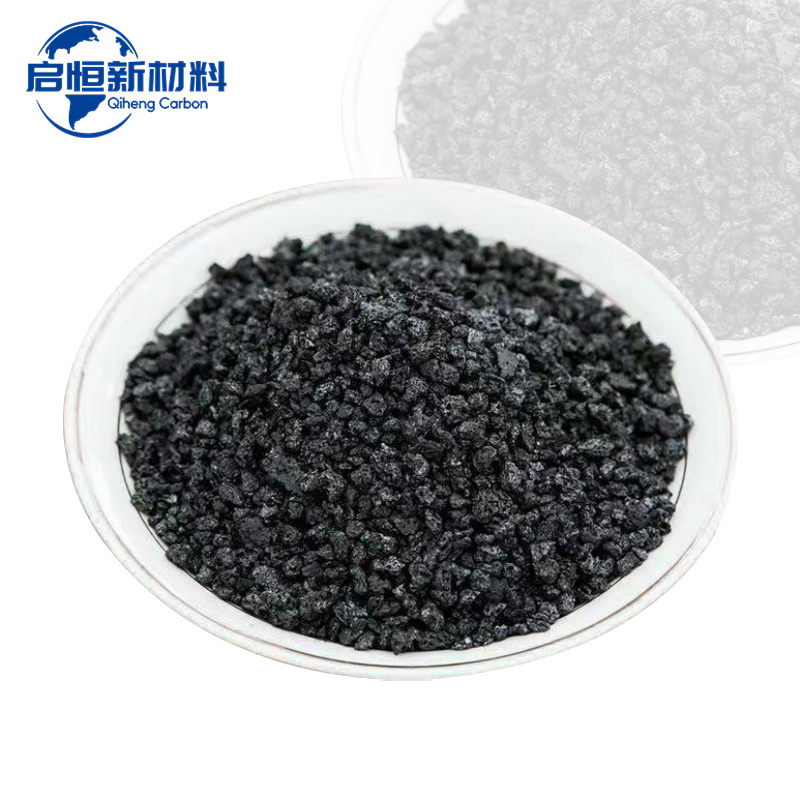

Calcined petroleum coke (CPC) is a crucial material derived from the thermal treatment of green petroleum coke, a byproduct of the oil refining process. The significance of CPC in the petrochemical industry cannot be overstated, as it serves multiple essential functions across various sectors. Understanding the properties and applications of calcined petroleum coke can greatly benefit those involv

Calcined petroleum coke (CPC) is a crucial material derived from the thermal treatment of green petroleum coke, a byproduct of the oil refining process. The significance of CPC in the petrochemical industry cannot be overstated, as it serves multiple essential functions across various sectors. Understanding the properties and applications of calcined petroleum coke can greatly benefit those involved in industries reliant on this unique substance.

The production of calcined petroleum coke involves heating green petroleum coke in a rotary kiln at high temperatures (typically between 1200°C and 1400°C). This process drives off volatile compounds, resulting in a dense, carbon-rich product. The calcination process not only enhances the carbon content but also improves the material's structural integrity. This makes CPC an ideal choice for applications that require high thermal and electrical conductivity.

One of the primary uses of calcined petroleum coke is in the aluminum industry, where it serves as a key component in the production of anodes. Anodes are essential for the electrolysis process used to extract aluminum from its ore, bauxite. The high purity and low levels of sulfur and ash in CPC make it particularly well-suited for this application, as they ensure efficient and environmentally friendly aluminum production.

Additionally, calcined petroleum coke is extensively used in the production of graphite electrodes, which are vital for electric arc furnaces in steelmaking. The high carbon content of CPC supports the high-temperature processes required in steel production, providing the necessary electrical conductivity and stability under extreme conditions.

Another significant application of calcined petroleum coke is in the manufacturing of various carbon products, including carbon black, which is used in tires, coatings, and plastics. The unique properties of CPC facilitate the production of high-quality carbon black, which enhances the performance and durability of these materials.

Moreover, the growing demand for cleaner energy solutions has led to an increased interest in the use of calcined petroleum coke in the production of synthetic fuels and other environmentally friendly energy sources. As industries seek to reduce their carbon footprints, CPC's role as a precursor to various carbon-based materials becomes even more relevant.

In conclusion, calcined petroleum coke is a vital component in numerous applications within the petrochemical industry, particularly in aluminum production, steelmaking, and carbon product manufacturing. Its unique properties, derived from the calcination process, enable it to meet the high demands of these industries. Understanding the significance and versatility of CPC is essential for stakeholders looking to enhance their operations and contribute to a more sustainable future.

The production of calcined petroleum coke involves heating green petroleum coke in a rotary kiln at high temperatures (typically between 1200°C and 1400°C). This process drives off volatile compounds, resulting in a dense, carbon-rich product. The calcination process not only enhances the carbon content but also improves the material's structural integrity. This makes CPC an ideal choice for applications that require high thermal and electrical conductivity.

One of the primary uses of calcined petroleum coke is in the aluminum industry, where it serves as a key component in the production of anodes. Anodes are essential for the electrolysis process used to extract aluminum from its ore, bauxite. The high purity and low levels of sulfur and ash in CPC make it particularly well-suited for this application, as they ensure efficient and environmentally friendly aluminum production.

Additionally, calcined petroleum coke is extensively used in the production of graphite electrodes, which are vital for electric arc furnaces in steelmaking. The high carbon content of CPC supports the high-temperature processes required in steel production, providing the necessary electrical conductivity and stability under extreme conditions.

Another significant application of calcined petroleum coke is in the manufacturing of various carbon products, including carbon black, which is used in tires, coatings, and plastics. The unique properties of CPC facilitate the production of high-quality carbon black, which enhances the performance and durability of these materials.

Moreover, the growing demand for cleaner energy solutions has led to an increased interest in the use of calcined petroleum coke in the production of synthetic fuels and other environmentally friendly energy sources. As industries seek to reduce their carbon footprints, CPC's role as a precursor to various carbon-based materials becomes even more relevant.

In conclusion, calcined petroleum coke is a vital component in numerous applications within the petrochemical industry, particularly in aluminum production, steelmaking, and carbon product manufacturing. Its unique properties, derived from the calcination process, enable it to meet the high demands of these industries. Understanding the significance and versatility of CPC is essential for stakeholders looking to enhance their operations and contribute to a more sustainable future.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property