Essential Insights on Graphite Electrode Connectors for Electrical Applications

Summary:

Essential Insights on Graphite Electrode Connectors for Electrical Applications

Table of Contents

1. Introduction to Graphite Electrode Connectors

2. Importance of Graphite Electrode Connectors in Electrical Applications

3. Types of Graphite Electrode Connectors

4. Selecting the Right Graphite Electrode Connector

5. Installation Techniques for Optimal Performance

6. Maintenance and Ca

Essential Insights on Graphite Electrode Connectors for Electrical Applications

Table of Contents

- 1. Introduction to Graphite Electrode Connectors

- 2. Importance of Graphite Electrode Connectors in Electrical Applications

- 3. Types of Graphite Electrode Connectors

- 4. Selecting the Right Graphite Electrode Connector

- 5. Installation Techniques for Optimal Performance

- 6. Maintenance and Care for Graphite Electrode Connectors

- 7. Common Applications of Graphite Electrode Connectors

- 8. Future Trends in Graphite Electrode Connector Technology

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Graphite Electrode Connectors

Graphite electrode connectors play a pivotal role in various electrical applications, providing a reliable interface for conducting electricity. These connectors are designed to withstand high temperatures and corrosion, making them ideal for demanding environments such as electrical furnaces and heavy machinery. Understanding their properties and functionalities is crucial for engineers and professionals involved in electrical installations and repairs.

2. Importance of Graphite Electrode Connectors in Electrical Applications

The importance of graphite electrode connectors lies in their ability to facilitate efficient energy transfer while minimizing resistance. When properly utilized, these connectors can enhance the overall performance of electrical systems. Their benefits include:

2.1 High Electrical Conductivity

Graphite has a high degree of electrical conductivity, which allows for effective energy transfer with minimal loss. This characteristic is essential in applications requiring high power and efficiency.

2.2 Thermal Stability

Graphite connectors can operate at elevated temperatures without degrading, making them suitable for industrial environments where heat is a significant factor.

2.3 Corrosion Resistance

Unlike metals, graphite is resistant to many forms of chemical corrosion, which extends the lifespan of connectors in hostile conditions.

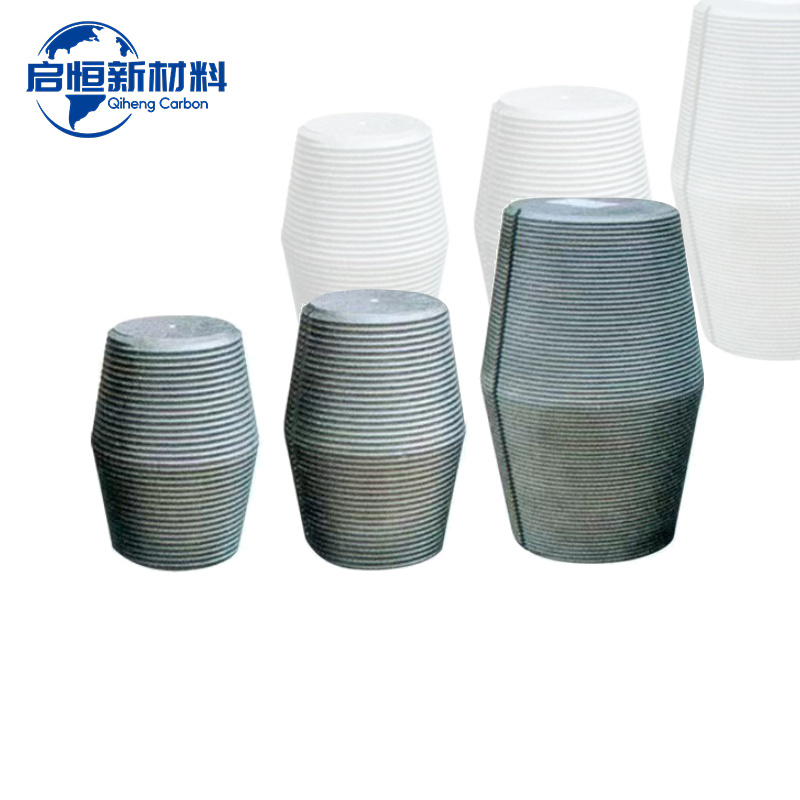

3. Types of Graphite Electrode Connectors

There are various types of graphite electrode connectors, each designed for specific applications and requirements. Understanding these types can help in selecting the right connector for your project.

3.1 Standard Graphite Connectors

These are commonly used in various electrical applications where standard specifications are sufficient. They provide good conductivity and thermal stability.

3.2 Customized Graphite Connectors

For specialized applications, customized connectors can be designed to meet specific requirements, such as unique shapes or sizes, ensuring optimal performance in unique environments.

3.3 Flexible Graphite Connectors

Flexible connectors are ideal for environments where movement or vibration is a concern. They provide a reliable connection while accommodating motion without compromising performance.

4. Selecting the Right Graphite Electrode Connector

Choosing the appropriate graphite electrode connector is critical to ensuring the efficiency and reliability of your electrical application. Here are some key factors to consider:

4.1 Voltage and Current Ratings

Ensure that the selected connector meets the voltage and current requirements of your application. Exceeding these ratings can lead to failures or safety hazards.

4.2 Environmental Conditions

Consider the environmental factors such as temperature, humidity, and potential exposure to corrosive elements when selecting connectors.

4.3 Compatibility with Existing Systems

Check that the dimensions and types of connectors you choose are compatible with your existing wiring and equipment.

5. Installation Techniques for Optimal Performance

Proper installation of graphite electrode connectors is essential for maximizing their performance and longevity. Here are some recommended techniques:

5.1 Preparing the Connection Site

Before installation, ensure that the connection site is clean and free from debris or corrosion. This preparation helps achieve a secure and efficient connection.

5.2 Using the Correct Tools

Utilize appropriate tools for the installation, including wrenches and torque tools, to ensure that connections are tightened to the manufacturer’s specifications.

5.3 Regular Testing

After installation, conduct electrical tests to verify that the connections are performing correctly and safely. Regular testing can prevent issues down the line.

6. Maintenance and Care for Graphite Electrode Connectors

Maintaining graphite electrode connectors is vital for ensuring their longevity and effectiveness. Here are some maintenance tips:

6.1 Regular Inspections

Perform routine inspections to identify wear and tear, corrosion, or any loose connections. Early detection can prevent more significant issues.

6.2 Cleaning Procedures

Keep connectors clean from dust and contaminants. Use appropriate cleaning agents that won’t damage the graphite material.

6.3 Replacing Worn Connectors

When connectors show signs of significant wear or damage, replace them promptly to maintain system integrity and performance.

7. Common Applications of Graphite Electrode Connectors

Graphite electrode connectors are utilized in a wide range of applications across different industries, including:

7.1 Electric Arc Furnaces

In steelmaking, graphite electrode connectors are used in electric arc furnaces, facilitating the high electrical currents necessary for melting steel.

7.2 Resistive Heating Systems

These connectors are integral in resistive heating systems where they ensure efficient energy transfer for heating applications.

7.3 Electrical Conductors in Heavy Machinery

In heavy machinery, graphite connectors help maintain reliable electrical connections, ensuring optimal machine performance.

8. Future Trends in Graphite Electrode Connector Technology

The evolution of graphite electrode connectors is ongoing, driven by advancements in materials science and engineering. Future trends may include:

8.1 Enhanced Materials

Research is underway to create even more efficient graphite materials that can withstand higher temperatures and currents.

8.2 Smart Connectors

The integration of smart technologies into connectors may provide real-time monitoring of performance, helping to prevent failures before they occur.

8.3 Sustainability Initiatives

The push for sustainable practices is leading to the development of eco-friendly manufacturing processes for graphite connectors, minimizing their environmental impact.

9. Frequently Asked Questions

Q1: What are graphite electrode connectors made of?

A: Graphite electrode connectors are primarily made from high-purity graphite, which provides excellent electrical conductivity and thermal stability.

Q2: How do I know if my graphite connector is failing?

A: Signs of failure may include excessive heat generation, visible wear, discoloration, or any unusual noises during operation.

Q3: Can graphite connectors be used outdoors?

A: Yes, but it is essential to ensure they are protected from moisture and corrosive elements to prolong their lifespan.

Q4: What is the lifespan of a graphite electrode connector?

A: The lifespan can vary widely depending on environmental conditions and usage, but with proper maintenance, they can last several years.

Q5: Are there any safety precautions I should take when working with graphite connectors?

A: Always ensure that systems are powered down before handling connectors and use appropriate personal protective equipment (PPE) to prevent electrical hazards.

10. Conclusion

Graphite electrode connectors are essential components in numerous electrical applications, providing reliability, efficiency, and durability. By understanding their significance, types, selection criteria, installation techniques, and maintenance best practices, professionals can ensure optimal performance in their electrical systems. As technology continues to advance, staying informed about future trends and innovations will enable engineers and technicians to make proactive decisions, ultimately enhancing the effectiveness of their electrical applications.

Previous:

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property