Understanding Graphite Electrodes for Steel Making: Essential Insights for Industry Professionals

Summary:

Graphite electrodes are indispensable components in the steel-making process, particularly in electric arc furnaces (EAF). These electrodes facilitate the electrical conduction needed to melt scrap steel and produce new steel products, highlighting their importance in modern metallurgy. This article will delve into the characteristics, benefits, and applications of graphite electrodes, providing v

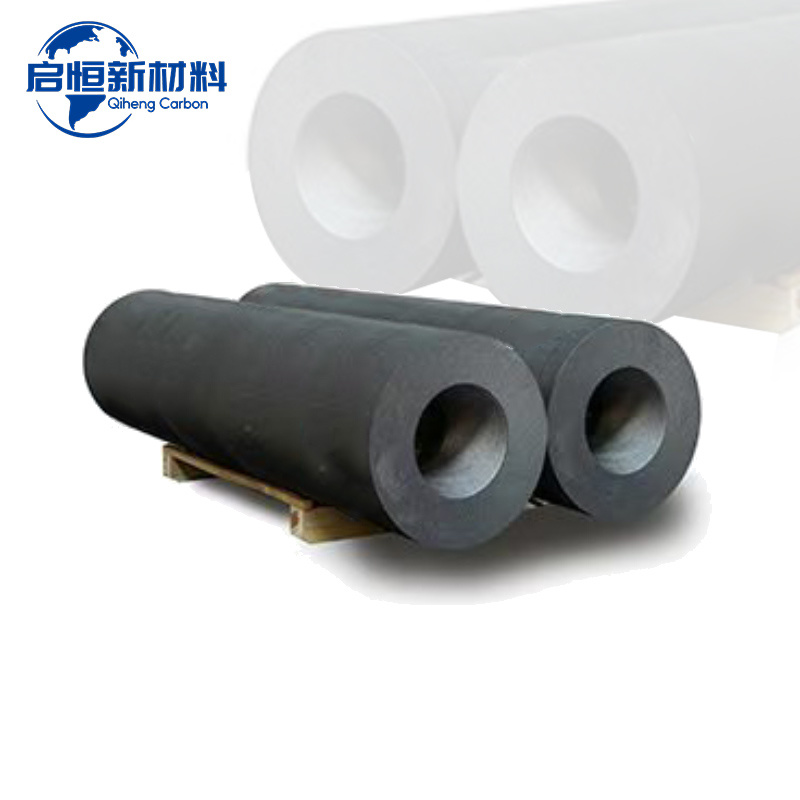

Graphite electrodes are indispensable components in the steel-making process, particularly in electric arc furnaces (EAF). These electrodes facilitate the electrical conduction needed to melt scrap steel and produce new steel products, highlighting their importance in modern metallurgy. This article will delve into the characteristics, benefits, and applications of graphite electrodes, providing valuable insights for industry professionals.

First and foremost, the structure of graphite electrodes plays a significant role in their effectiveness. Composed primarily of high-purity graphite, these electrodes possess excellent thermal and electrical conductivity, which is crucial during the steel-making process. Their high-temperature resistance ensures that they can withstand the intense conditions within the EAF, allowing for efficient melting and refining of steel.

Another important aspect of graphite electrodes is their performance efficiency. They are designed to operate in high-heat environments, minimizing the risk of oxidation and prolonging their lifespan. This durability not only reduces the frequency of replacements but also enhances the overall efficiency of the steel-making process, leading to lower production costs in the long run.

Moreover, the use of graphite electrodes aligns with the increasing emphasis on sustainability within the steel industry. As the demand for recycled steel rises, the reliance on EAFs, which utilize graphite electrodes, also increases. This method of steel production is generally more energy-efficient compared to traditional blast furnace methods, offering a more sustainable alternative that reduces greenhouse gas emissions.

In addition to their functional advantages, graphite electrodes are also versatile in application. They can accommodate various steel grades and compositions, making them suitable for a wide range of steel products. As the steel industry evolves, so too does the technology surrounding graphite electrodes, with ongoing research and development aimed at improving their performance and sustainability.

To summarize, graphite electrodes are essential for the efficient and sustainable production of steel. Their superior conductivity, high-temperature resistance, and adaptability make them vital components in electric arc furnaces. As the steel industry continues to innovate, the role of graphite electrodes will undoubtedly remain central to achieving both economic and environmental goals.

In conclusion, understanding the significance of graphite electrodes for steel making is crucial for professionals in the metallurgy and energy sectors. By leveraging the properties and applications of these electrodes, industry stakeholders can enhance operational efficiency while contributing to a more sustainable future in steel production.

First and foremost, the structure of graphite electrodes plays a significant role in their effectiveness. Composed primarily of high-purity graphite, these electrodes possess excellent thermal and electrical conductivity, which is crucial during the steel-making process. Their high-temperature resistance ensures that they can withstand the intense conditions within the EAF, allowing for efficient melting and refining of steel.

Another important aspect of graphite electrodes is their performance efficiency. They are designed to operate in high-heat environments, minimizing the risk of oxidation and prolonging their lifespan. This durability not only reduces the frequency of replacements but also enhances the overall efficiency of the steel-making process, leading to lower production costs in the long run.

Moreover, the use of graphite electrodes aligns with the increasing emphasis on sustainability within the steel industry. As the demand for recycled steel rises, the reliance on EAFs, which utilize graphite electrodes, also increases. This method of steel production is generally more energy-efficient compared to traditional blast furnace methods, offering a more sustainable alternative that reduces greenhouse gas emissions.

In addition to their functional advantages, graphite electrodes are also versatile in application. They can accommodate various steel grades and compositions, making them suitable for a wide range of steel products. As the steel industry evolves, so too does the technology surrounding graphite electrodes, with ongoing research and development aimed at improving their performance and sustainability.

To summarize, graphite electrodes are essential for the efficient and sustainable production of steel. Their superior conductivity, high-temperature resistance, and adaptability make them vital components in electric arc furnaces. As the steel industry continues to innovate, the role of graphite electrodes will undoubtedly remain central to achieving both economic and environmental goals.

In conclusion, understanding the significance of graphite electrodes for steel making is crucial for professionals in the metallurgy and energy sectors. By leveraging the properties and applications of these electrodes, industry stakeholders can enhance operational efficiency while contributing to a more sustainable future in steel production.

Previous:

Focus On Hot Spots

Understanding Graphite Electrodes for Steel Making: Essential Insights for Industry Professionals

Graphite electrodes are indispensable components in the steel-making process, particularly in electric arc furnaces (EAF). These electrodes facilitate the electrical conduction needed to melt scrap steel and produce new steel products, highlighting their importance in modern metallurgy. This article will delve into the characteristics, benefits, and applications of graphite electrodes, providing v

Exploring Alternative Materials to UHP Graphite Electrodes in Metallurgy and Energy

Exploring Alternative Materials to UHP Graphite Electrodes in Metallurgy and Energy

Table of Contents

1. Introduction to UHP Graphite Electrodes

2. Importance of UHP Graphite Electrodes in Industry

3. Challenges Faced by UHP Graphite Electrodes

4. Exploring Alternative Materials to UHP Graphite Electrodes

4.1 Silicon Carbide (SiC)

4.2 Copper-Based