Understanding High Power Graphite Electrode: A Key Component in Metallurgical Industries

Summary:

High power graphite electrodes (HPGE) play a crucial role in various metallurgical processes, particularly in electric arc furnaces (EAF) used for steel manufacturing and other metal recycling operations. Their ability to withstand high temperatures and conductive properties makes them indispensable in these applications. As industries strive for efficiency and sustainability, understanding the te

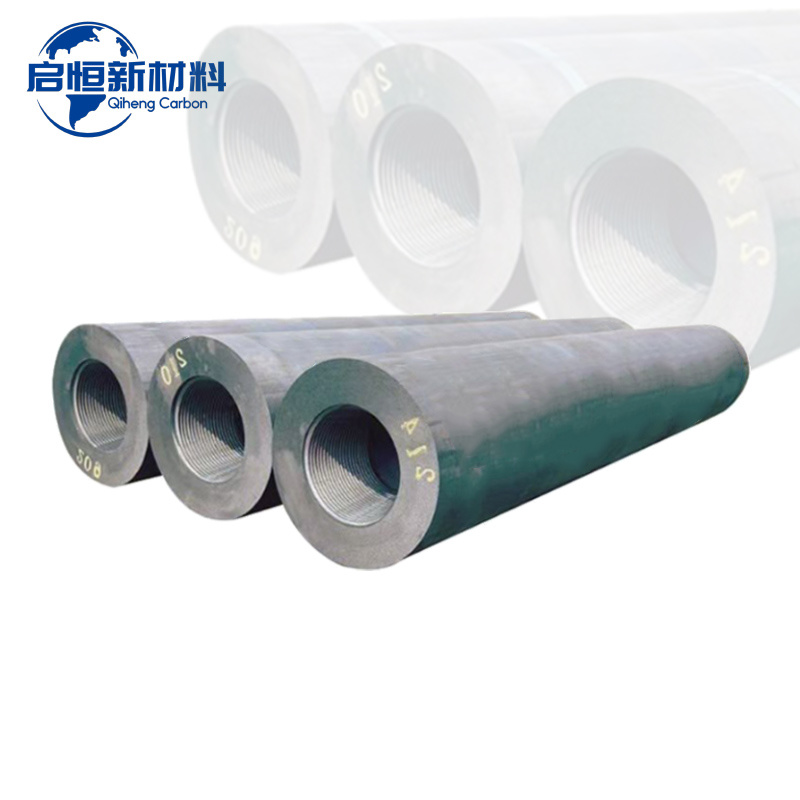

High power graphite electrodes (HPGE) play a crucial role in various metallurgical processes, particularly in electric arc furnaces (EAF) used for steel manufacturing and other metal recycling operations. Their ability to withstand high temperatures and conductive properties makes them indispensable in these applications. As industries strive for efficiency and sustainability, understanding the technical aspects of HPGE is essential for professionals in the metallurgy and energy sectors.

One of the key characteristics of high power graphite electrodes is their excellent thermal conductivity, which enhances the efficiency of electric arc furnaces. The electrodes facilitate optimal electric conduction, ensuring that the furnace operates at the desired temperature for melting and refining metals. This property is particularly important in processes that require precise temperature management, as it directly affects the quality of the end product.

The manufacturing process of HPGE includes a series of complex steps, starting with the selection of high-quality raw materials, such as petroleum needle coke and petroleum pitch. These materials are subjected to high-temperature treatment, resulting in a dense and durable electrode that can withstand the intense conditions within an EAF. Advances in technology have led to the development of improved grades of graphite that offer enhanced performance, including increased mechanical strength and resistance to oxidation.

In addition to their traditional applications, high power graphite electrodes are increasingly being used in emerging technologies such as lithium-ion battery production and renewable energy systems. As the demand for electric vehicles and energy storage solutions grows, the role of graphite electrodes in these industries becomes more prominent. Professionals in the graphite sector should stay informed about these trends, as they represent significant opportunities for innovation and growth.

Moreover, sustainability is a critical consideration in the production and use of HPGE. With the global push towards reducing carbon emissions, manufacturers are exploring eco-friendly alternatives and production methods. For instance, recycling used graphite electrodes not only helps reduce waste but also minimizes the environmental impact associated with the extraction of raw materials.

In conclusion, high power graphite electrodes are vital components in the metallurgy and energy sectors, with wide-ranging applications that extend beyond traditional uses. Professionals in the non-metallic minerals and graphite industry must stay abreast of technological advancements and sustainability initiatives to remain competitive. By understanding the properties, manufacturing processes, and emerging applications of HPGE, stakeholders can better navigate the evolving landscape of the industry and contribute to its sustainable future.

One of the key characteristics of high power graphite electrodes is their excellent thermal conductivity, which enhances the efficiency of electric arc furnaces. The electrodes facilitate optimal electric conduction, ensuring that the furnace operates at the desired temperature for melting and refining metals. This property is particularly important in processes that require precise temperature management, as it directly affects the quality of the end product.

The manufacturing process of HPGE includes a series of complex steps, starting with the selection of high-quality raw materials, such as petroleum needle coke and petroleum pitch. These materials are subjected to high-temperature treatment, resulting in a dense and durable electrode that can withstand the intense conditions within an EAF. Advances in technology have led to the development of improved grades of graphite that offer enhanced performance, including increased mechanical strength and resistance to oxidation.

In addition to their traditional applications, high power graphite electrodes are increasingly being used in emerging technologies such as lithium-ion battery production and renewable energy systems. As the demand for electric vehicles and energy storage solutions grows, the role of graphite electrodes in these industries becomes more prominent. Professionals in the graphite sector should stay informed about these trends, as they represent significant opportunities for innovation and growth.

Moreover, sustainability is a critical consideration in the production and use of HPGE. With the global push towards reducing carbon emissions, manufacturers are exploring eco-friendly alternatives and production methods. For instance, recycling used graphite electrodes not only helps reduce waste but also minimizes the environmental impact associated with the extraction of raw materials.

In conclusion, high power graphite electrodes are vital components in the metallurgy and energy sectors, with wide-ranging applications that extend beyond traditional uses. Professionals in the non-metallic minerals and graphite industry must stay abreast of technological advancements and sustainability initiatives to remain competitive. By understanding the properties, manufacturing processes, and emerging applications of HPGE, stakeholders can better navigate the evolving landscape of the industry and contribute to its sustainable future.

Previous:

Focus On Hot Spots

Understanding High Power Graphite Electrode: A Key Component in Metallurgical Industries

High power graphite electrodes (HPGE) play a crucial role in various metallurgical processes, particularly in electric arc furnaces (EAF) used for steel manufacturing and other metal recycling operations. Their ability to withstand high temperatures and conductive properties makes them indispensable in these applications. As industries strive for efficiency and sustainability, understanding the te

Maximizing Efficiency and Performance: Best Practices for Graphite Electrodes in Electric Arc Furnaces

Table of Contents

1. Introduction to Graphite Electrodes and Electric Arc Furnaces

2. Understanding Graphite Electrodes: Properties and Types

3. The Role of Graphite Electrodes in Electric Arc Furnaces

4. Best Practices for Using Graphite Electrodes

4.1 Selec