The Versatile World of Graphite Powder: Applications and Benefits

Summary:

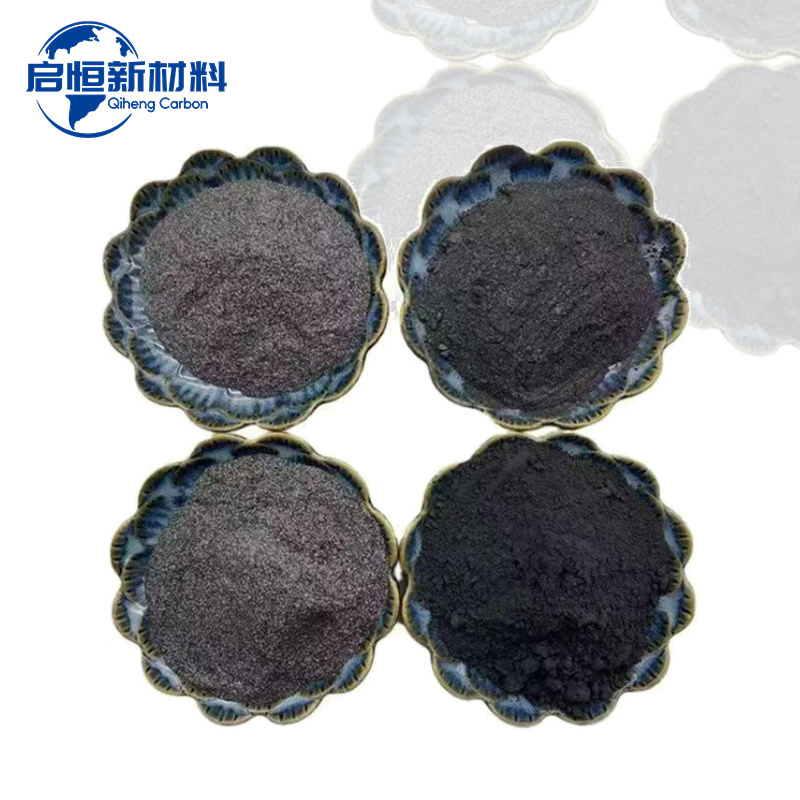

Graphite powder, a fine form of crystalline carbon, is renowned for its unique properties, making it a valuable component across several industries. As a versatile non-metallic mineral, graphite powder is characterized by its excellent thermal conductivity, chemical stability, and lubricating properties. These attributes make it indispensable in metallurgy, energy, and other sectors that require h

Graphite powder, a fine form of crystalline carbon, is renowned for its unique properties, making it a valuable component across several industries. As a versatile non-metallic mineral, graphite powder is characterized by its excellent thermal conductivity, chemical stability, and lubricating properties. These attributes make it indispensable in metallurgy, energy, and other sectors that require high-performance materials.

One of the primary applications of graphite powder is in the production of refractory materials. These are essential in high-temperature processes, such as those found in metallurgical furnaces. Graphite’s ability to withstand extreme temperatures without decomposing makes it ideal for linings in smelting and casting processes. By enhancing the durability and efficiency of these materials, graphite powder contributes significantly to the longevity of industrial equipment.

In the energy sector, graphite powder is increasingly utilized in batteries, particularly in lithium-ion batteries. It serves as an anode material, playing a vital role in the energy storage capabilities of these batteries. The high electrical conductivity of graphite allows for efficient electron flow, enhancing overall battery performance. As demand for renewable energy sources continues to rise, the role of graphite powder in energy storage solutions becomes even more critical.

Another notable application of graphite powder is in lubricants. Its layered structure allows for easy slippage between layers, which reduces friction and wear in mechanical components. This property is particularly advantageous in high-pressure applications where traditional lubricants may fail. Graphite powder-based lubricants are widely used in industries ranging from automotive to aerospace, enabling smoother operations and extending the life of machinery.

Moreover, the cosmetic and pharmaceutical industries have begun to recognize the potential of graphite powder. In cosmetics, it is used for its aesthetic properties, providing a shimmering effect in formulations. In pharmaceuticals, its inert nature and non-reactivity make it suitable as a filler in tablet production.

It is also worth noting that graphite powder has a lower environmental impact compared to many synthetic alternatives. Its natural occurrence and ability to be sourced sustainably align with the growing trend toward eco-friendly materials in manufacturing processes.

In conclusion, graphite powder stands out as a remarkable substance with widespread applications across various industries. Its unique properties not only enhance industrial processes but also contribute to the development of innovative solutions in energy storage, lubrication, and beyond. Understanding its multifaceted benefits can help businesses make informed decisions about integrating graphite powder into their products and processes.

One of the primary applications of graphite powder is in the production of refractory materials. These are essential in high-temperature processes, such as those found in metallurgical furnaces. Graphite’s ability to withstand extreme temperatures without decomposing makes it ideal for linings in smelting and casting processes. By enhancing the durability and efficiency of these materials, graphite powder contributes significantly to the longevity of industrial equipment.

In the energy sector, graphite powder is increasingly utilized in batteries, particularly in lithium-ion batteries. It serves as an anode material, playing a vital role in the energy storage capabilities of these batteries. The high electrical conductivity of graphite allows for efficient electron flow, enhancing overall battery performance. As demand for renewable energy sources continues to rise, the role of graphite powder in energy storage solutions becomes even more critical.

Another notable application of graphite powder is in lubricants. Its layered structure allows for easy slippage between layers, which reduces friction and wear in mechanical components. This property is particularly advantageous in high-pressure applications where traditional lubricants may fail. Graphite powder-based lubricants are widely used in industries ranging from automotive to aerospace, enabling smoother operations and extending the life of machinery.

Moreover, the cosmetic and pharmaceutical industries have begun to recognize the potential of graphite powder. In cosmetics, it is used for its aesthetic properties, providing a shimmering effect in formulations. In pharmaceuticals, its inert nature and non-reactivity make it suitable as a filler in tablet production.

It is also worth noting that graphite powder has a lower environmental impact compared to many synthetic alternatives. Its natural occurrence and ability to be sourced sustainably align with the growing trend toward eco-friendly materials in manufacturing processes.

In conclusion, graphite powder stands out as a remarkable substance with widespread applications across various industries. Its unique properties not only enhance industrial processes but also contribute to the development of innovative solutions in energy storage, lubrication, and beyond. Understanding its multifaceted benefits can help businesses make informed decisions about integrating graphite powder into their products and processes.

The next one:

Focus On Hot Spots

Understanding Graphite Blocks: Key Insights for the Metallurgical and Energy Sector

Graphite blocks are a crucial component in various applications within the metallurgy and energy sectors, particularly in the realm of non-metallic mineral products. These blocks are primarily composed of crystallized carbon and exhibit a unique combination of properties that make them highly desirable for industrial applications. Understanding the characteristics and advantages of graphite blocks

The Environmental Impact of Graphite Square Production: A Comprehensive Analysis

The Environmental Impact of Graphite Square Production

Table of Contents

1. Introduction to Graphite Square Production

2. Understanding the Graphite Production Process

3. Key Environmental Challenges Associated with Graphite Production

4. Analyzing the Carbon Footprint of Graphite Squares

5. Water Usage and Pollution Concerns

6. Waste Management Practices in Graphite Produ