Petroleum Coke: A Key Player in Fuel Efficiency

Summary:

Petroleum Coke: A Key Player in Fuel Efficiency

Table of Contents

1. Introduction to Petroleum Coke

2. Understanding Petroleum Coke

3. Production Processes of Petroleum Coke

4. Properties and Types of Petroleum Coke

5. Applications of Petroleum Coke in Various Industries

6. The Impact of Petroleum Coke on Fuel Efficiency

7. Environmental Considerations of Petroleum Cok

Petroleum Coke: A Key Player in Fuel Efficiency

Table of Contents

- 1. Introduction to Petroleum Coke

- 2. Understanding Petroleum Coke

- 3. Production Processes of Petroleum Coke

- 4. Properties and Types of Petroleum Coke

- 5. Applications of Petroleum Coke in Various Industries

- 6. The Impact of Petroleum Coke on Fuel Efficiency

- 7. Environmental Considerations of Petroleum Coke

- 8. The Future of Petroleum Coke in Energy

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Petroleum Coke

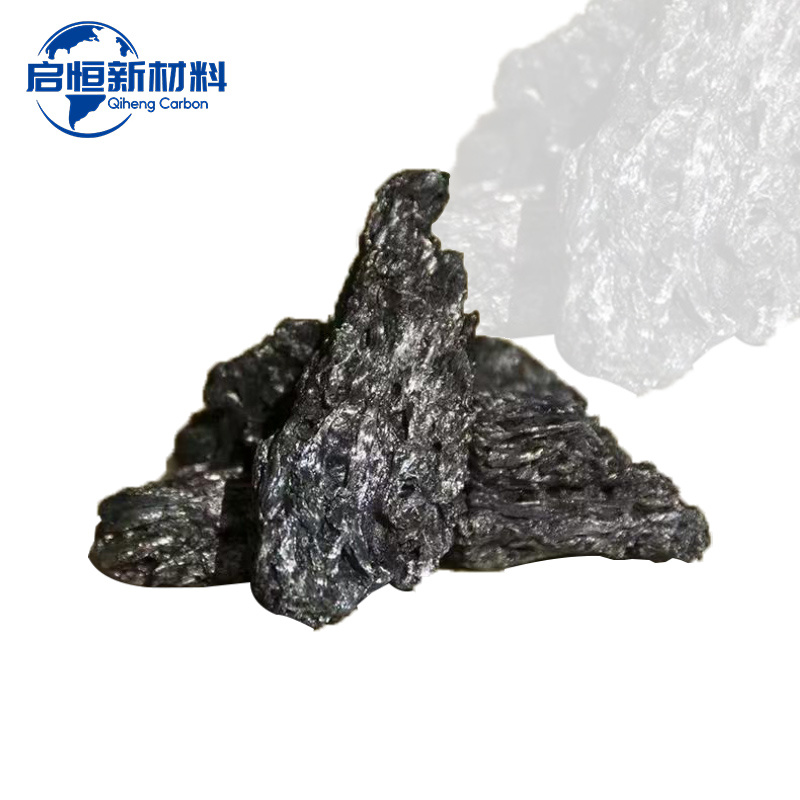

Petroleum coke, commonly known as petcoke, is a carbon-rich solid product derived from the oil refining process. As a byproduct of crude oil distillation, it has gained prominence in various sectors, particularly in enhancing fuel efficiency. With a growing emphasis on sustainable practices, understanding the role of petroleum coke is critical for industries focusing on energy efficiency and environmental responsibility.

2. Understanding Petroleum Coke

Petroleum coke is a byproduct formed during the thermal cracking process of crude oil. This process involves breaking down heavy hydrocarbon feedstocks into lighter products, leaving behind a carbon-rich material. Petcoke can be categorized into two primary types: **green petroleum coke** and **calcined petroleum coke**. Green petcoke is produced directly from the oil refining process, while calcined petcoke undergoes additional heating to enhance its properties for specific applications.

2.1 The Chemical Composition of Petroleum Coke

Petcoke is primarily composed of carbon (about 80-90%), with varying amounts of hydrogen, sulfur, nitrogen, and trace metals. This unique composition contributes to its high calorific value, making it an effective fuel source.

3. Production Processes of Petroleum Coke

The production of petroleum coke involves several complex processes, typically beginning with crude oil distillation. During this process, heavier fractions are subjected to extreme heat and pressure, breaking down the molecules into simpler forms.

3.1 Thermal Cracking

Thermal cracking is a critical step in generating petcoke. It involves heating heavy oils in the presence of a catalyst, leading to the formation of lighter hydrocarbons and solid carbon materials.

3.2 Delayed Coking

In the delayed coking process, heavy residues are heated in a coker unit, where the vaporized hydrocarbons are removed, and the remaining carbon is formed into petroleum coke. This method optimizes the production of high-quality petcoke.

4. Properties and Types of Petroleum Coke

Petroleum coke possesses distinct characteristics that influence its usability across various industries. The properties are primarily defined by its type—green or calcined.

4.1 Green Petroleum Coke

Green petroleum coke is characterized by its high sulfur content and relatively low carbon purity. It is generally used in the production of anodes for aluminum smelting or as a fuel source in industrial processes.

4.2 Calcined Petroleum Coke

Calcined petroleum coke is obtained by heating green petcoke in a calcining kiln. This process drives off volatile components and enhances its carbon content, making it suitable for higher-end applications such as electrodes in steel and aluminum manufacturing.

5. Applications of Petroleum Coke in Various Industries

The diverse applications of petroleum coke span several industries, primarily due to its high energy density and carbon content.

5.1 Aluminum Industry

In the aluminum industry, calcined petroleum coke serves as a crucial component in producing anodes. These anodes facilitate the electrochemical reduction of aluminum oxide into aluminum metal.

5.2 Cement Industry

Petcoke is increasingly utilized as a supplemental fuel in cement kilns. Its high calorific value and low ash content contribute to improved combustion efficiency, reducing production costs.

5.3 Power Generation

Petroleum coke is also utilized in power generation, where it can function as a coal substitute. The transition to petcoke offers a more efficient combustion process, leading to enhanced energy output.

5.4 Other Industrial Applications

Beyond the aluminum and cement industries, petcoke finds applications in the manufacture of carbon black, graphite electrodes, and other carbon-based products.

6. The Impact of Petroleum Coke on Fuel Efficiency

Petcoke plays a vital role in enhancing fuel efficiency across various sectors. Its high carbon content and calorific value contribute to its effectiveness as a fuel source.

6.1 Enhanced Combustion Efficiency

When utilized in industrial boilers and furnaces, petroleum coke offers improved combustion efficiency compared to traditional fuels. This optimization reduces fuel consumption and lowers operational costs.

6.2 Reduced Emissions

Using petroleum coke can lead to lower greenhouse gas emissions when compared to other fossil fuels. Its combustion typically results in fewer harmful pollutants, contributing to cleaner energy production.

7. Environmental Considerations of Petroleum Coke

While petroleum coke presents numerous benefits, it also comes with environmental considerations that warrant attention.

7.1 Carbon Footprint

The production and combustion of petcoke can contribute to carbon emissions. However, when compared to coal, petcoke often results in a lower carbon footprint due to its higher efficiency.

7.2 Regulatory Challenges

The use of petroleum coke is subject to environmental regulations. Industries must adhere to strict guidelines to mitigate the potential environmental impact associated with its use.

8. The Future of Petroleum Coke in Energy

As industries pivot toward sustainable practices, the future of petroleum coke appears promising. Innovations in processing techniques and applications may further enhance its role in energy efficiency.

8.1 Technological Advancements

Developments in processing technology aim to improve the purity and reduce the environmental impact of petroleum coke. These advancements could make petcoke an even more attractive option for energy applications.

8.2 Growing Market Demand

With increasing energy demands and a push for cleaner fuels, the market for petroleum coke is expected to grow. Its versatility in various applications positions it as a key player in future energy solutions.

9. Frequently Asked Questions

9.1 What is petroleum coke used for?

Petroleum coke is primarily used in the aluminum and cement industries, as well as in power generation and the manufacture of carbon products.

9.2 Is petroleum coke environmentally friendly?

While it has a lower carbon footprint compared to coal, the environmental impact of petroleum coke depends on its production and combustion methods.

9.3 How does petroleum coke enhance fuel efficiency?

Petcoke enhances fuel efficiency through its high calorific value and improved combustion characteristics, reducing overall fuel consumption.

9.4 What are the main types of petroleum coke?

The two main types are green petroleum coke and calcined petroleum coke, each with specific properties and applications.

9.5 What industries use petroleum coke?

Key industries include aluminum, cement, power generation, and various manufacturing sectors that require carbon-based products.

10. Conclusion

In summary, petroleum coke is a significant contributor to fuel efficiency across various industrial applications. Its unique properties make it an essential material in energy-intensive sectors, paving the way for enhanced operational efficiencies and reduced emissions. As industries continue to evolve and seek sustainable practices, the role of petroleum coke is expected to expand, solidifying its position as a key player in the future of energy solutions.

Focus On Hot Spots

Understanding Graphite Blocks: Key Insights for the Metallurgical and Energy Sector

Graphite blocks are a crucial component in various applications within the metallurgy and energy sectors, particularly in the realm of non-metallic mineral products. These blocks are primarily composed of crystallized carbon and exhibit a unique combination of properties that make them highly desirable for industrial applications. Understanding the characteristics and advantages of graphite blocks

The Environmental Impact of Graphite Square Production: A Comprehensive Analysis

The Environmental Impact of Graphite Square Production

Table of Contents

1. Introduction to Graphite Square Production

2. Understanding the Graphite Production Process

3. Key Environmental Challenges Associated with Graphite Production

4. Analyzing the Carbon Footprint of Graphite Squares

5. Water Usage and Pollution Concerns

6. Waste Management Practices in Graphite Produ