Petroleum Coke’s Role in the Global Energy Landscape: Key Insights and Future Prospects

Summary:

Petroleum Coke’s Role in the Global Energy Landscape

Table of Contents

1. Introduction to Petroleum Coke

2. What is Petroleum Coke?

3. The Production Process of Petroleum Coke

4. Applications of Petroleum Coke in Various Industries

5. Economic Significance of Petroleum Coke

6. Environmental Impact of Petroleum Coke

7. Future Trends in Petroleum Coke C

Petroleum Coke’s Role in the Global Energy Landscape

Table of Contents

- 1. Introduction to Petroleum Coke

- 2. What is Petroleum Coke?

- 3. The Production Process of Petroleum Coke

- 4. Applications of Petroleum Coke in Various Industries

- 5. Economic Significance of Petroleum Coke

- 6. Environmental Impact of Petroleum Coke

- 7. Future Trends in Petroleum Coke Consumption

- 8. Frequently Asked Questions about Petroleum Coke

- 9. Conclusion

1. Introduction to Petroleum Coke

Petroleum coke, often referred to as petcoke, is a carbonaceous solid derived from oil refining processes. It has garnered significant attention in recent years due to its increasing usage as a fuel and industrial feedstock. As global energy demands evolve, so does the role of petroleum coke in meeting these needs. This article provides an in-depth exploration of petroleum coke's significance in the energy landscape, examining its production, applications, economic impact, and environmental considerations.

2. What is Petroleum Coke?

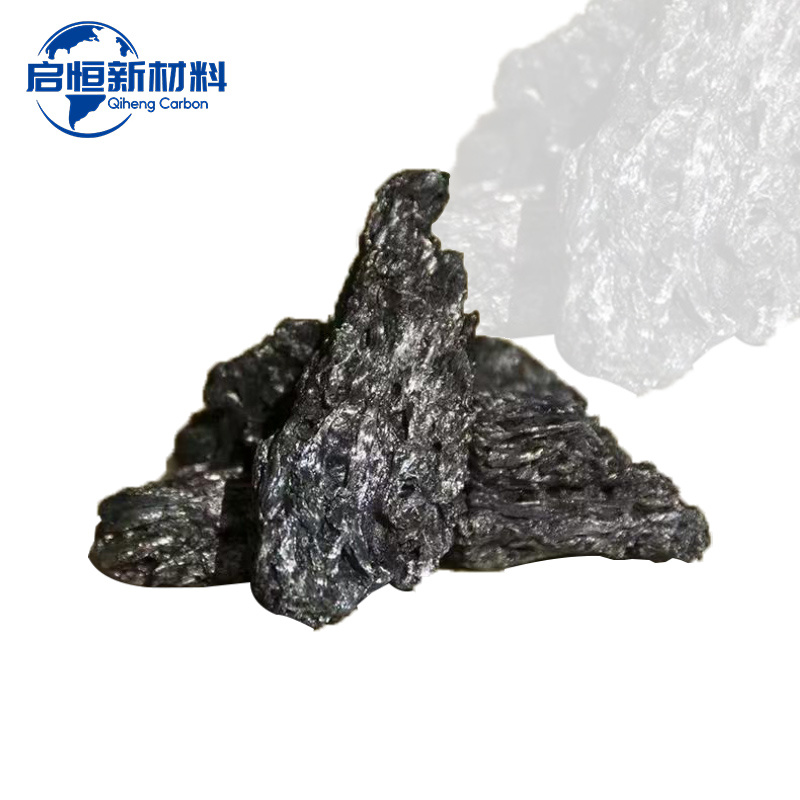

Petroleum coke is a byproduct of the oil refining process, specifically through the coking process, where heavier fractions of crude oil are converted into lighter products. It is characterized by its high carbon content, typically exceeding 80%, making it an effective fuel source. Petcoke comes in two primary forms: **green petroleum coke** and **calcined petroleum coke**. Green petcoke is produced directly from the coking process, while calcined petcoke undergoes a secondary process of heating to remove volatile compounds, enhancing its carbon content and making it suitable for various industrial applications.

2.1 Characteristics of Petroleum Coke

Petcoke boasts several key characteristics that make it a sought-after commodity in the energy sector:

- **High Carbon Content**: With a carbon content exceeding 90% in calcined forms, petcoke serves as a highly efficient energy source.

- **Low Sulfur**: Depending on the source and refining process, petcoke can have low sulfur content, which is favorable for various applications, particularly in cement manufacturing.

- **Economic Efficiency**: The cost-effectiveness of petcoke compared to other fossil fuels makes it an attractive option for energy production and industrial uses.

3. The Production Process of Petroleum Coke

The production of petroleum coke involves several key steps:

1. **Crude Oil Distillation**: Crude oil is heated and separated into various fractions through distillation.

2. **Coking Process**: Heavier fractions are subjected to high temperatures in a coker unit, leading to the formation of petroleum coke and lighter hydrocarbons.

3. **Cooling and Handling**: The produced coke is cooled, then crushed and screened to create different sizing grades suitable for downstream applications.

The efficiency of the coking process and the subsequent handling of petcoke are critical for maximizing yield and ensuring product quality.

4. Applications of Petroleum Coke in Various Industries

Petroleum coke finds applications across several industries, showcasing its versatility as a raw material and energy source.

4.1 Energy Production

Petcoke is increasingly used as a fuel in power generation. Its high energy density and low cost make it an attractive alternative to coal and natural gas. As countries strive for energy security, petcoke's role in power plants continues to grow, particularly in regions with abundant supply.

4.2 Cement Manufacturing

One of the most significant applications of calcined petroleum coke is in cement production. Its high carbon content enables it to serve as a cost-effective fuel and a source of carbon for the clinker production process. The cement industry relies heavily on petcoke to reduce costs while maintaining the necessary energy input for production.

4.3 Aluminum Production

Calcined petroleum coke is a critical ingredient in aluminum smelting. It acts as a carbon source in the electrolytic reduction process, contributing to the production of aluminum from alumina. The aluminum industry’s demand for high-quality calcined petcoke is driven by its need for efficiency and lower emissions.

4.4 Other Industrial Uses

Beyond energy production and aluminum manufacturing, petcoke is used in various industrial applications, including the production of graphite electrodes, steel manufacturing, and as a filler in certain chemical processes. Its versatility supports numerous sectors, reinforcing its importance in global trade.

5. Economic Significance of Petroleum Coke

The economic implications of petroleum coke are substantial, influencing markets and trade patterns globally.

5.1 Market Dynamics

As the demand for energy continues to rise, the market for petroleum coke has expanded significantly. Countries rich in crude oil reserves, particularly in the Middle East, North America, and parts of Asia, dominate petcoke production. This concentration influences global pricing and availability, creating opportunities for trade among nations.

5.2 Employment and Growth Opportunities

The petroleum coke industry contributes to job creation and economic growth, particularly in regions where oil refining and energy production are central to local economies. Investments in refining technology and infrastructure can further stimulate growth, resulting in enhanced productivity and efficiency.

5.3 Price Volatility

While petroleum coke is generally cost-effective, its pricing can be volatile, influenced by crude oil prices, global supply and demand, and regulatory changes. Understanding these dynamics is crucial for stakeholders involved in the production and consumption of petcoke.

6. Environmental Impact of Petroleum Coke

Despite its economic benefits, the environmental impact of petroleum coke raises concerns among policymakers and environmentalists.

6.1 Greenhouse Gas Emissions

Burning petroleum coke releases greenhouse gases, contributing to climate change. As a high-carbon fuel, its usage in power generation and industrial processes must be balanced against global efforts to reduce carbon footprints.

6.2 Pollution and Health Risks

The combustion of petcoke can lead to air pollutants, including sulfur oxides and particulate matter, which pose health risks to nearby communities. Regulatory frameworks are increasingly focusing on emissions standards to mitigate these impacts.

6.3 Sustainable Alternatives

As environmental awareness grows, there is a push for cleaner energy sources. The petroleum coke industry is exploring carbon capture and storage technologies to reduce emissions and enhance sustainability. Additionally, transitioning to renewable energy sources remains a central goal for many governments.

7. Future Trends in Petroleum Coke Consumption

The future of petroleum coke is shaped by evolving energy landscapes and technological innovations.

7.1 Shift Toward Cleaner Technologies

The adoption of cleaner technologies and carbon capture methods is expected to shape the way petcoke is utilized. These advancements aim to minimize environmental impacts while maximizing energy efficiency.

7.2 Diversification of Uses

As industries seek to enhance efficiency and reduce costs, the diversification of petroleum coke applications will likely continue. New technologies may unlock additional uses, making petcoke an even more valuable commodity.

7.3 Regulatory Changes

Stricter regulations regarding emissions and environmental impact are anticipated, influencing how petcoke is produced and consumed. Companies will need to adapt to these changes to remain competitive in the global market.

8. Frequently Asked Questions about Petroleum Coke

8.1 What is the difference between green and calcined petroleum coke?

Green petroleum coke is the raw form produced during the coking process, while calcined petroleum coke undergoes additional heating to enhance its carbon content and remove volatile substances.

8.2 How is petroleum coke used in the cement industry?

Calcined petroleum coke serves as a fuel and a carbon source in cement production, helping to reduce costs while supplying the necessary energy for the clinker process.

8.3 Is petroleum coke environmentally friendly?

While petroleum coke is cost-effective and energy-dense, its combustion does produce greenhouse gases and pollutants. Mitigating these impacts is a focus of ongoing research and regulatory efforts.

8.4 What are the economic benefits of using petroleum coke?

Using petroleum coke can lower energy costs, support job creation in refining industries, and drive market growth, particularly in energy-intensive sectors.

8.5 What trends are shaping the future of petroleum coke?

Future trends include a shift towards cleaner technologies, diversification of applications, and adapting to regulatory changes that may impact production and consumption.

9. Conclusion

Petroleum coke plays a pivotal role in the global energy landscape, serving as a vital source of fuel and industrial feedstock. Its high carbon content, cost-effectiveness, and diverse applications underscore its importance across various sectors. However, the environmental implications of its use necessitate a careful balance between economic benefits and sustainability. As the energy sector evolves, the future of petroleum coke will depend on technological advancements, regulatory frameworks, and the ongoing pursuit of cleaner energy solutions. Understanding these dynamics is essential for stakeholders looking to navigate the complexities of the energy market effectively.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property