The Significance of UHP Graphite Electrodes in High-Temperature Applications

Summary:

The Significance of UHP Graphite Electrodes in High-Temperature Applications

Table of Contents

Introduction to UHP Graphite Electrodes

Understanding UHP Graphite Electrodes

Key Properties of UHP Graphite Electrodes

Applications of UHP Graphite Electrodes in High-Temperature Environments

Advantages of Using UHP Graphite Electrodes

Manufacturing Process of UHP Graphite Elect

The Significance of UHP Graphite Electrodes in High-Temperature Applications

Table of Contents

- Introduction to UHP Graphite Electrodes

- Understanding UHP Graphite Electrodes

- Key Properties of UHP Graphite Electrodes

- Applications of UHP Graphite Electrodes in High-Temperature Environments

- Advantages of Using UHP Graphite Electrodes

- Manufacturing Process of UHP Graphite Electrodes

- Comparison with Other High-Temperature Materials

- Future Trends in UHP Graphite Electrodes

- Frequently Asked Questions

- Conclusion

Introduction to UHP Graphite Electrodes

In today’s rapidly evolving industrial landscape, the demand for efficient and reliable materials has never been greater. **Ultra High-Performance (UHP) graphite electrodes** have emerged as a cornerstone of high-temperature applications, particularly within industries such as steelmaking and the production of silicon metals. These electrodes are distinguished by their exceptional electrical conductivity, thermal resistance, and mechanical strength, making them an invaluable asset in processes that demand high temperatures and precise control.

Understanding UHP Graphite Electrodes

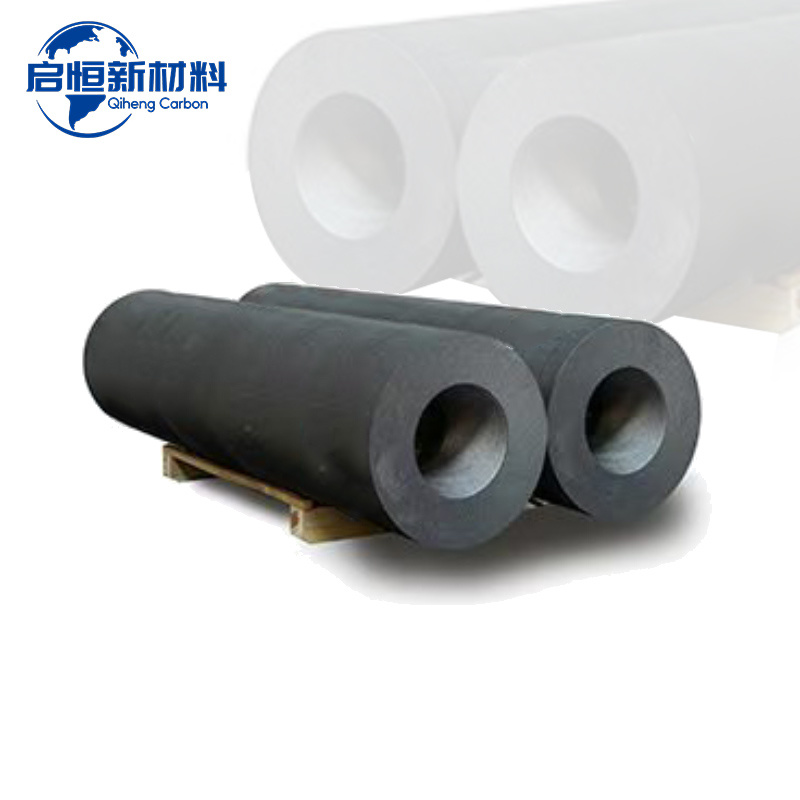

UHP graphite electrodes are specifically designed for electric arc furnaces (EAFs), which are essential for steel production and recycling processes. The uniqueness of UHP electrodes lies in their manufacturing process, which involves high-quality petroleum needle coke as the primary raw material. This results in a dense, isotropic structure that is critical for high-performance applications.

The electrodes come in varying sizes, typically ranging from 75 mm to 600 mm in diameter, and can be customized to meet the specific needs of different industrial applications. The dimensions and properties of UHP graphite electrodes directly influence the efficiency and productivity of the processes in which they are utilized.

Key Properties of UHP Graphite Electrodes

UHP graphite electrodes possess several key properties that make them ideal for high-temperature applications:

1. High Electrical Conductivity

UHP graphite electrodes exhibit excellent electrical conductivity, which is crucial for efficient energy transfer during the electric arc furnace process. This property minimizes energy loss, optimizing overall operational efficiency.

2. Superior Thermal Stability

The ability to withstand high temperatures without degrading is a defining characteristic of UHP graphite electrodes. They maintain structural integrity and performance even at temperatures exceeding 3000°C, making them suitable for intense industrial environments.

3. Mechanical Strength

UHP graphite electrodes are known for their high tensile strength, which allows them to endure the mechanical stresses associated with electric arc furnace operations. This durability results in reduced wear and tear, leading to longer operational lifespans.

4. Low Coefficient of Thermal Expansion

A low coefficient of thermal expansion ensures that UHP graphite electrodes maintain their shape and dimensional stability as they are subjected to extreme temperature fluctuations. This characteristic is vital for maintaining the efficiency and effectiveness of the processes they serve.

Applications of UHP Graphite Electrodes in High-Temperature Environments

UHP graphite electrodes are utilized across various high-temperature applications, with the following being the most prominent:

1. Electric Arc Furnaces (EAF)

The primary application of UHP graphite electrodes is in EAFs, where they facilitate the recycling of steel and the production of new steel. The electrodes create electric arcs that generate the intense heat necessary to melt scrap steel, enabling efficient recycling and reducing reliance on traditional blast furnace methods.

2. Production of Silicon Metal

In the production of silicon metal, UHP graphite electrodes play a crucial role in maintaining the high temperatures required for the chemical reactions involved. Silicon metal is vital in the manufacturing of semiconductors, solar panels, and various alloys.

3. Ferroalloy Production

UHP graphite electrodes are also employed in the production of ferroalloys, which are essential for various metallurgical processes. These alloys enhance the properties of steel and other metals, making them more suitable for specific applications.

4. Carbon Black Manufacturing

In the production of carbon black, UHP graphite electrodes are used to sustain the high temperatures needed to produce this critical material. Carbon black is widely used in the rubber industry and as a pigment in various applications.

Advantages of Using UHP Graphite Electrodes

Employing UHP graphite electrodes offers several advantages that contribute to improved operational efficiency and product quality:

1. Cost-Effectiveness

While the initial investment in UHP graphite electrodes may be higher than traditional electrodes, their durability and performance lead to reduced operational costs in the long run. The extended lifespan and lower maintenance costs make UHP electrodes a cost-effective solution for many industries.

2. Enhanced Productivity

The superior conductivity and thermal stability of UHP graphite electrodes enable faster melting and refining processes. This increased productivity translates to higher output rates and improved overall process efficiency.

3. Environmental Benefits

The use of UHP graphite electrodes in recycling processes helps minimize waste and reduce the carbon footprint associated with steel production. By facilitating the recycling of scrap metal, these electrodes contribute to a more sustainable industrial ecosystem.

4. Improved Product Quality

UHP graphite electrodes enable the production of high-quality steel and other alloys with less contamination and better overall properties. This improvement in product quality is a significant advantage for manufacturers aiming to meet stringent industry standards.

Manufacturing Process of UHP Graphite Electrodes

The manufacturing process of UHP graphite electrodes is intricate and involves several key steps:

1. Raw Material Selection

The quality of UHP graphite electrodes begins with the selection of raw materials, primarily **petroleum needle coke**. This material is chosen for its high purity and superior crystallinity, which contribute to the final properties of the electrodes.

2. Calcination

The selected needle coke undergoes calcination, a process that involves heating the material to high temperatures in the absence of air. This step removes volatile components and transforms the coke into a dense, carbon-rich material.

3. Mixing and Molding

The calcined coke is then mixed with a binder pitch that helps hold the structure together. The mixture is subsequently molded into the desired shape and size of the electrode.

4. Baking

After molding, the electrodes are baked at high temperatures to further strengthen their structure. This process drives off any remaining volatile substances and enhances the bonding between the carbon particles.

5. Graphitization

The final step in the manufacturing process is graphitization, where the baked electrodes are subjected to even higher temperatures, typically exceeding 2500°C. This step converts the carbon structure into graphite, resulting in the desired properties of UHP electrodes.

Comparison with Other High-Temperature Materials

When comparing UHP graphite electrodes to alternative materials used in high-temperature applications, several factors come into play:

1. Vs. Traditional Graphite Electrodes

UHP graphite electrodes outperform traditional graphite electrodes in terms of electrical conductivity, thermal stability, and mechanical strength. This makes them a preferred choice in demanding applications.

2. Vs. Ceramic Materials

While ceramics may possess high temperature resistance, they often lack the electrical conductivity necessary for EAF operations. UHP graphite electrodes provide an optimal balance of conductivity and thermal stability that ceramics cannot match.

3. Vs. Metal Electrodes

Metal electrodes, while conductive, are prone to oxidation and corrosion at high temperatures. UHP graphite electrodes, on the other hand, maintain their integrity and performance under extreme conditions, making them a more reliable choice.

Future Trends in UHP Graphite Electrodes

As industries continue to evolve, several trends are shaping the future of UHP graphite electrodes:

1. Advancements in Material Science

Ongoing research in material science aims to enhance the properties of UHP graphite electrodes further, focusing on improving their conductivity and thermal resistance through novel composite materials.

2. Increased Demand for Sustainable Practices

The push for sustainability within industries is likely to drive the development of UHP graphite electrodes that support environmental goals, emphasizing recycling and energy efficiency.

3. Technological Innovations

Innovations in manufacturing technologies can lead to more efficient production processes, reducing costs and enhancing the performance of UHP graphite electrodes.

Frequently Asked Questions

1. What are UHP graphite electrodes primarily used for?

UHP graphite electrodes are predominantly used in electric arc furnaces for steel production, silicon metal manufacturing, and ferroalloy production.

2. How do UHP graphite electrodes compare to traditional electrodes?

UHP graphite electrodes offer superior electrical conductivity, thermal stability, and mechanical strength compared to traditional graphite electrodes, making them more effective in high-temperature applications.

3. What are the environmental benefits of using UHP graphite electrodes?

The use of UHP graphite electrodes in recycling processes reduces waste and lowers the carbon footprint associated with steel production, contributing to more sustainable industrial practices.

4. Can UHP graphite electrodes be customized?

Yes, UHP graphite electrodes can be customized in size and properties to meet the specific requirements of various industrial applications.

5. What does the manufacturing process of UHP graphite electrodes involve?

The manufacturing process includes raw material selection, calcination, mixing and molding, baking, and graphitization to create electrodes with high performance characteristics.

Conclusion

In summary, **Ultra High-Performance (UHP) graphite electrodes** are integral to high-temperature applications across various industries. Their unique properties, including high electrical conductivity, thermal stability, and mechanical strength, enhance the efficiency and productivity of processes like steelmaking and the production of silicon metals. As industries continue to pursue sustainability and technological innovation, the significance of UHP graphite electrodes will only grow, solidifying their place as a critical material in modern manufacturing. The ongoing advancements in material science and manufacturing techniques promise a bright future for UHP graphite electrodes, ensuring they remain indispensable in high-temperature applications for years to come.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property