Comparative Analysis: Graphite Square vs. Other Carbon Products - A Comprehensive Guide

Summary:

Comparative Analysis: Graphite Square vs. Other Carbon Products

Table of Contents

1. Introduction to Graphite and Carbon Products

2. What is Graphite Square?

3. Overview of Other Carbon Products

4. Comparative Analysis of Key Properties

5. Applications of Graphite Square vs. Other Carbon Products

6. Advantages of Graphite Square

7. Sustainability and Environmental Impa

Comparative Analysis: Graphite Square vs. Other Carbon Products

Table of Contents

- 1. Introduction to Graphite and Carbon Products

- 2. What is Graphite Square?

- 3. Overview of Other Carbon Products

- 4. Comparative Analysis of Key Properties

- 5. Applications of Graphite Square vs. Other Carbon Products

- 6. Advantages of Graphite Square

- 7. Sustainability and Environmental Impact

- 8. Future Trends in the Carbon Product Market

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Graphite and Carbon Products

Graphite and other carbon products play a pivotal role in numerous industries, including electronics, aerospace, and energy. Carbon's unique properties make it indispensable in applications ranging from batteries to lubricants. Among these various forms, **Graphite Square** has emerged as a noteworthy contender, especially in specialized applications. This article provides a thorough comparative analysis to highlight the distinctions and advantages of Graphite Square in relation to other carbon products.

2. What is Graphite Square?

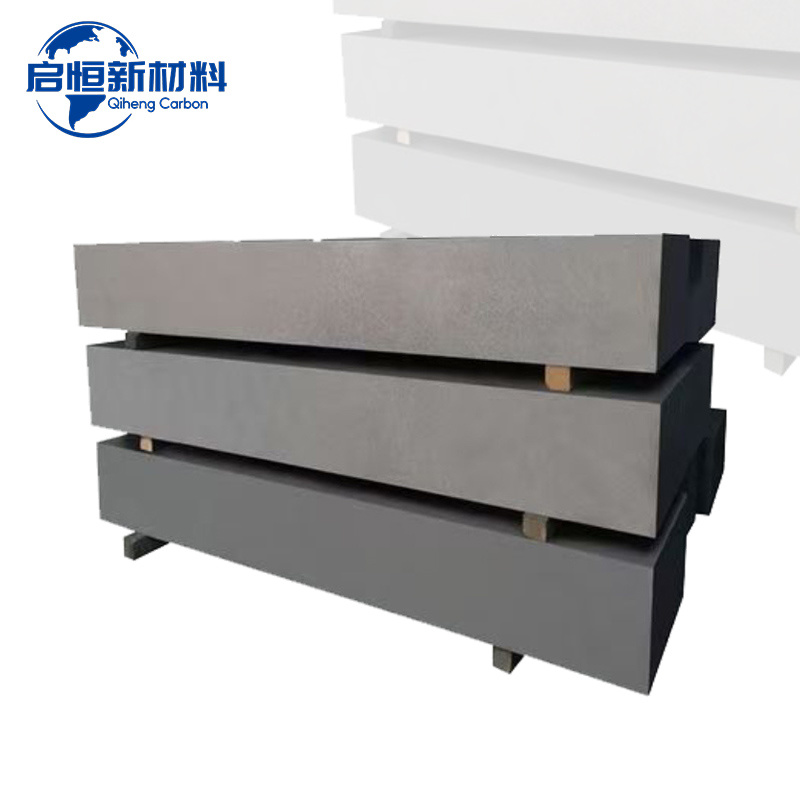

**Graphite Square** is a specialized form of graphite designed for high-performance applications. It is characterized by its unique square shape, which optimizes surface area and enhances conductivity. This form is commonly utilized in industries that require precise electrical and thermal performance, such as semiconductor manufacturing and advanced materials development. The physical structure of Graphite Square allows for improved packing density, making it a preferred choice for companies looking to maximize efficiency and performance in their products.

3. Overview of Other Carbon Products

In comparison, **other carbon products** include a variety of forms such as carbon black, activated carbon, and amorphous carbon. Each type has distinct characteristics and applications:

- **Carbon Black**: Primarily used in tires and coatings, it enhances durability and provides black pigmentation.

- **Activated Carbon**: Known for its adsorption properties, it is widely used in filtration systems and air purification.

- **Amorphous Carbon**: Commonly found in inks and coatings, offering versatility but lacking the structured benefits of graphite.

These carbon forms serve their specific purposes; however, they may not match the performance metrics that Graphite Square provides in critical applications.

4. Comparative Analysis of Key Properties

When assessing Graphite Square against other carbon products, several key properties come into play:

4.1 Electrical Conductivity

Graphite Square exhibits exceptional electrical conductivity due to its high degree of crystallinity and structured form. In contrast, carbon black, while conductive, does not offer the same level of efficiency for high-current applications.

4.2 Thermal Conductivity

In terms of thermal conductivity, Graphite Square outperforms many other carbon forms. The square structure ensures optimal heat dissipation, making it ideal for applications like heat sinks and thermal interface materials.

4.3 Mechanical Strength

Graphite Square also boasts superior mechanical strength compared to amorphous carbon products. This strength is vital in applications requiring high structural integrity, such as battery electrodes and conductive composites.

4.4 Purity and Composition

The purity of Graphite Square is generally higher than that of carbon black and activated carbon, which often contain impurities from their production processes. This purity translates to enhanced performance, particularly in sensitive electronic applications.

5. Applications of Graphite Square vs. Other Carbon Products

The applications of Graphite Square span various industries due to its unique properties:

5.1 Electronics

In the electronics industry, Graphite Square is utilized for manufacturing components such as **electrodes**, **conductive films**, and **battery materials**. Its superior conductivity is particularly beneficial for high-performance devices.

5.2 Aerospace

Aerospace applications also favor Graphite Square for its lightweight and strong characteristics. It is often used in the production of composite materials that require excellent thermal and electrical performance.

5.4 Lubricants and Sealing Materials

Graphite's inherent lubricating properties make Graphite Square an ideal choice for high-temperature and high-pressure applications in lubricants and sealing materials, outperforming conventional carbon products.

6. Advantages of Graphite Square

The advantages of choosing Graphite Square over other carbon products are numerous:

6.1 Enhanced Performance

With its superior conductivity and thermal management capabilities, Graphite Square enhances the performance of end products, leading to increased efficiency and reliability.

6.2 Cost-Effectiveness

Although Graphite Square may have a higher upfront cost compared to traditional carbon products, the long-term benefits—such as improved performance and reduced failure rates—often lead to lower overall costs.

6.3 Versatility

Graphite Square is adaptable for a range of applications, from electronics to aerospace, making it a versatile choice for manufacturers looking to streamline their product lines.

7. Sustainability and Environmental Impact

Sustainability is a growing concern in the production of industrial materials. Graphite Square is primarily derived from natural sources, and advancements in extraction and manufacturing processes are aimed at reducing environmental impact. In contrast, some other carbon products, like carbon black, involve significant emissions during production. Choosing Graphite Square can contribute to a more sustainable industrial practice.

8. Future Trends in the Carbon Product Market

The market for carbon products, including Graphite Square, is expected to grow as industries evolve and demand for high-performance materials increases. Key trends include:

- **Increased Demand for Lightweight Materials**: Industries such as automotive and aerospace are moving towards lighter materials for improved fuel efficiency, positioning Graphite Square well for future growth.

- **Advancements in Battery Technology**: As the demand for electric vehicles rises, Graphite Square's role in battery production is likely to expand, offering enhanced performance for energy storage solutions.

- **Sustainable Practices**: The push for sustainable materials will further highlight the advantages of Graphite Square as manufacturers seek eco-friendly options.

9. Frequently Asked Questions

9.1 What sets Graphite Square apart from other carbon products?

Graphite Square's unique structure allows for superior electrical and thermal conductivity, as well as increased mechanical strength compared to other carbon forms.

9.2 In which industries is Graphite Square primarily used?

Graphite Square is predominantly used in electronics, aerospace, automotive, and energy storage applications.

9.3 Is Graphite Square environmentally friendly?

Yes, Graphite Square is derived from natural sources and can be produced with reduced environmental impact compared to some other carbon products.

9.4 Can Graphite Square be used in high-temperature applications?

Absolutely, Graphite Square is known for its thermal stability, making it suitable for high-temperature applications.

9.5 What are the cost implications of using Graphite Square?

While the initial cost may be higher, the enhanced performance and reliability often lead to overall cost savings in manufacturing and product longevity.

10. Conclusion

The comparative analysis of Graphite Square versus other carbon products reveals significant advantages that make it a standout choice in various applications. Its superior electrical and thermal conductivity, mechanical strength, and sustainability features position Graphite Square as a frontrunner in the carbon material market. As industries continue to evolve and prioritize performance and eco-friendliness, Graphite Square is likely to play an increasingly important role in shaping future technologies. By choosing Graphite Square, manufacturers can enhance product efficiency and contribute to sustainable practices, ensuring a competitive edge in an ever-changing market landscape.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property