The Future of Electrical Connectors: A Comprehensive Exploration of Graphite Electrode Innovations

Summary:

The Future of Electrical Connectors: A Comprehensive Exploration of Graphite Electrode Innovations

Table of Contents

1. Introduction to Electrical Connectors

2. The Importance of Electrical Connectors in Modern Applications

3. Understanding Graphite Electrodes

4. Innovations in Graphite Electrode Technology

5. Advantages of Graphite Electrodes in Electrical Connectors

6. A

The Future of Electrical Connectors: A Comprehensive Exploration of Graphite Electrode Innovations

Table of Contents

- 1. Introduction to Electrical Connectors

- 2. The Importance of Electrical Connectors in Modern Applications

- 3. Understanding Graphite Electrodes

- 4. Innovations in Graphite Electrode Technology

- 5. Advantages of Graphite Electrodes in Electrical Connectors

- 6. Applications of Graphite Electrode Innovations

- 7. Sustainability and Environmental Impact

- 8. The Future Landscape of Electrical Connectors

- 9. Conclusion

- 10. Frequently Asked Questions

1. Introduction to Electrical Connectors

Electrical connectors serve as crucial components in a vast array of electronic devices. They facilitate the transmission of electrical power and signals between different segments of a system, ensuring that devices function seamlessly. As technology continues to evolve, so too does the design and capability of these connectors. The emergence of innovative materials, particularly graphite electrodes, is redefining how electrical connections are made.

2. The Importance of Electrical Connectors in Modern Applications

In our interconnected world, electrical connectors play a vital role in various sectors including telecommunications, automotive, consumer electronics, and industrial applications. The reliability, efficiency, and durability of these connectors directly impact the performance of electronic devices. As demand for more compact, efficient, and high-performance devices grows, so too does the need for advancements in electrical connector technology.

3. Understanding Graphite Electrodes

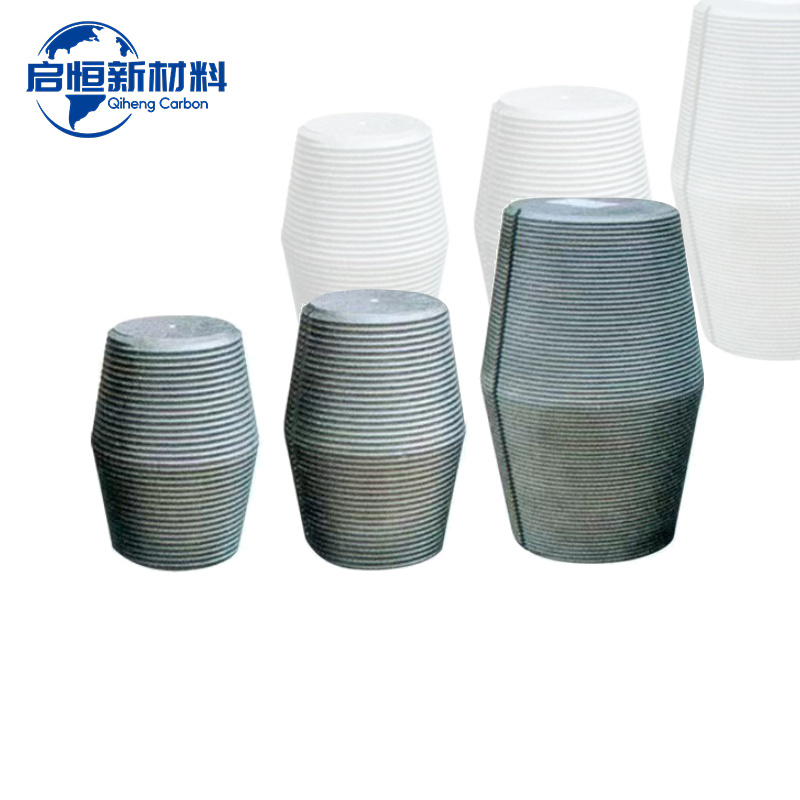

Graphite electrodes are made from high-purity graphite and are primarily used in electric arc furnaces for steelmaking and other metallurgical processes. Their ability to withstand extreme temperatures and electrical conductivity make them ideal for use in electrical connectors. This section explores the fundamental properties that make graphite an exceptional choice for modern electrical applications.

3.1 Properties of Graphite Electrodes

Graphite electrodes exhibit remarkable properties such as high thermal conductivity, excellent electrical conductivity, and mechanical strength. These attributes facilitate efficient energy transfer and reduce energy loss, making graphite an advantageous material for electrical connectors.

3.2 Manufacturing Processes of Graphite Electrodes

The manufacturing process of graphite electrodes involves several stages, including the selection of raw materials, mixing, molding, baking, and graphitization. Each step is crucial in determining the final properties of the electrodes, ensuring they meet the high demands of various applications.

4. Innovations in Graphite Electrode Technology

Recent advancements in graphite electrode technology have led to the development of various innovative designs and processes. These innovations aim to enhance performance, reduce production costs, and improve sustainability.

4.1 Enhanced Conductivity and Strength

Technological advancements have resulted in the creation of composite materials that combine graphite with other elements to enhance conductivity and strength. These new materials offer improved performance in electrical connectors, allowing for more efficient energy transfer and greater durability.

4.2 Customization and Scalability

The ability to customize graphite electrode designs for specific applications has become increasingly important. Manufacturers can now scale production based on the unique needs of different industries, facilitating greater adaptability and innovation in electrical connector designs.

5. Advantages of Graphite Electrodes in Electrical Connectors

The use of graphite electrodes in electrical connectors offers a multitude of advantages that enhance overall performance and reliability.

5.1 High Performance and Efficiency

Graphite electrodes provide superior performance in terms of electrical conductivity and thermal management. These characteristics allow for lower energy losses and improved overall efficiency in electrical systems.

5.2 Durability and Longevity

Graphite's inherent resistance to thermal shock and wear leads to longer-lasting electrical connectors. This durability translates to reduced maintenance costs and extended operational lifetimes for connected devices.

5.3 Lightweight Properties

The lightweight nature of graphite makes it an attractive option for industries where weight reduction is critical, such as aerospace and automotive applications. This attribute allows for more compact and efficient designs.

6. Applications of Graphite Electrode Innovations

The versatility of graphite electrodes enables them to be utilized across a wide range of applications, from industrial machinery to consumer electronics.

6.1 Telecommunications

In telecommunications, graphite electrodes are used in various connectors to ensure high-speed data transmission and reliable connections. Their ability to handle high frequencies makes them ideal for modern communication systems.

6.2 Automotive Industry

With the rise of electric vehicles (EVs), the automotive industry is increasingly adopting graphite electrode innovations to enhance battery performance and electrical systems. These electrodes facilitate efficient energy transfer, which is crucial for EV functionality.

6.3 Renewable Energy Systems

Graphite electrodes play a significant role in renewable energy systems, particularly in solar and wind energy applications. Their efficiency contributes to the effectiveness of energy storage solutions, such as batteries and capacitors.

7. Sustainability and Environmental Impact

As industries face growing pressures to adopt sustainable practices, graphite electrode technology is also adapting to meet environmental concerns.

7.1 Eco-Friendly Manufacturing Practices

Manufacturers are increasingly focusing on eco-friendly production methods for graphite electrodes, reducing waste and energy consumption during the manufacturing process. This commitment to sustainability is critical in minimizing the environmental footprint of electrical connectors.

7.2 Recyclability of Graphite

Graphite is a highly recyclable material, enabling the recovery of valuable resources from used electrodes. This recyclability aligns with global initiatives aimed at fostering a circular economy and reducing waste.

8. The Future Landscape of Electrical Connectors

The future of electrical connectors is bright, driven by continuous innovations in materials and designs. The integration of artificial intelligence and smart technologies is expected to further enhance the capabilities of graphite electrodes, leading to next-generation connectors that can adapt to various performance demands.

8.1 Anticipated Trends in Electrical Connector Design

Future trends indicate a shift towards miniaturization, higher power densities, and the incorporation of smart features in electrical connectors. These advancements will enhance connectivity and performance across multiple industries.

8.2 The Role of Research and Development

Ongoing research and development efforts are pivotal in unlocking new potential for graphite electrode innovations. Collaborations between academia and industry will play a significant role in driving technological advancements.

9. Conclusion

The evolution of electrical connectors, particularly through innovations in graphite electrode technology, marks a significant advancement in the field of electrical engineering. The unique properties of graphite contribute to enhanced performance, durability, and sustainability of electrical connectors across various applications. As we move towards a future fueled by technological advancement, graphite electrodes will undoubtedly play a crucial role in shaping the connected world.

10. Frequently Asked Questions

10.1 What are graphite electrodes used for in electrical connectors?

Graphite electrodes are utilized in electrical connectors due to their high electrical conductivity, thermal stability, and mechanical strength, making them ideal for efficient energy transfer.

10.2 How do graphite electrodes compare to traditional materials?

Graphite electrodes offer superior performance in terms of conductivity, durability, and weight compared to traditional materials, enhancing overall efficiency in electrical systems.

10.3 Are graphite electrodes environmentally friendly?

Yes, graphite electrodes are recyclable, and manufacturers are increasingly adopting eco-friendly production practices, making them a sustainable choice for electrical connectors.

10.4 In what industries are graphite electrodes most commonly used?

Graphite electrodes are commonly used in telecommunications, automotive, consumer electronics, and renewable energy systems, among others.

10.5 What are the future trends in electrical connector technology?

Future trends include miniaturization, higher power densities, smart features, and continuous innovation in materials, including advancements in graphite electrode technology.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property