What Makes Graphite Electrodes a Preferred Choice in Metallurgy?

Summary:

What Makes Graphite Electrodes a Preferred Choice in Metallurgy?

Understanding Graphite Electrodes in Metallurgy

Graphite electrodes hold a crucial place in the realm of metallurgy, particularly in electric arc furnaces (EAFs). These electrodes serve as a conduit for electrical currents, enabling the melting of metals and alloys efficiently. The demand for high-performance graphite electrodes has

What Makes Graphite Electrodes a Preferred Choice in Metallurgy?

Understanding Graphite Electrodes in Metallurgy

Graphite electrodes hold a crucial place in the realm of metallurgy, particularly in electric arc furnaces (EAFs). These electrodes serve as a conduit for electrical currents, enabling the melting of metals and alloys efficiently. The demand for high-performance graphite electrodes has grown significantly due to their unique properties, making them indispensable in various metallurgical processes.

The Composition and Properties of Graphite Electrodes

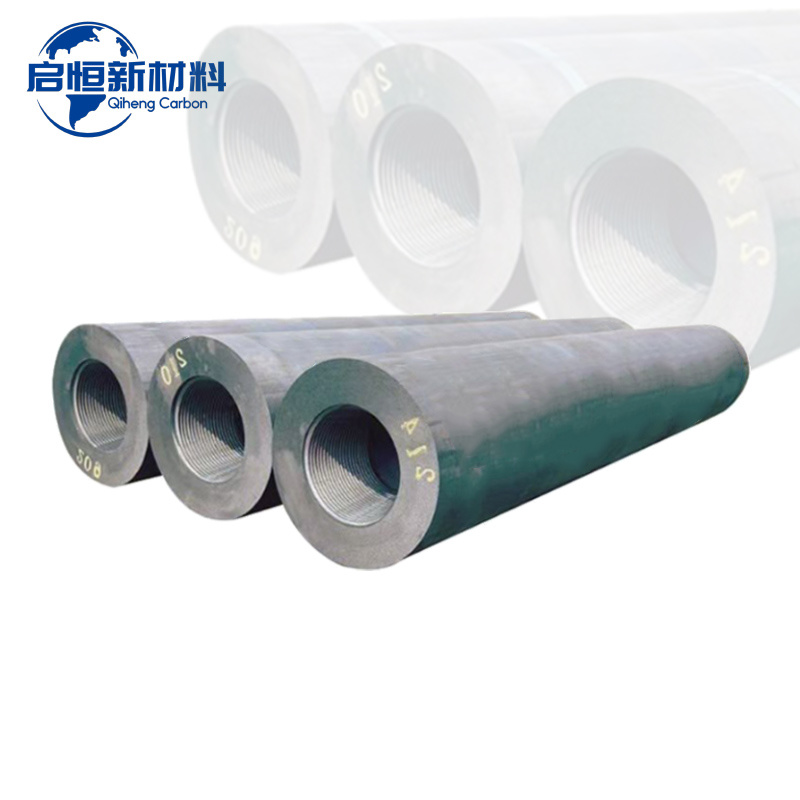

What Are Graphite Electrodes Made Of?

Graphite electrodes are primarily composed of high-purity petroleum and needle cokes. These materials are subjected to high temperatures in a baking process, transforming them into a solid, crystalline structure. The resulting electrodes exhibit several critical properties that enhance their performance in metallurgical applications.

Key Properties of Graphite Electrodes

1. **High Electrical Conductivity**: Graphite electrodes possess exceptional electrical conductivity, which is vital for efficient melting processes.

2. **Thermal Resistance**: The ability to withstand high temperatures without degrading is essential for the molten metal environment.

3. **Low Thermal Expansion**: This property minimizes the risk of cracking and ensures structural integrity under thermal stress.

4. **Chemical Stability**: Graphite electrodes resist oxidation and other chemical reactions, enhancing their lifespan during metallurgical operations.

Advantages of Using Graphite Electrodes

Efficiency in Electric Arc Furnaces

The integration of graphite electrodes in electric arc furnaces significantly enhances operational efficiency. Their high thermal and electrical conductivity results in faster melting times, reducing energy consumption and costs associated with metallurgical processes.

Cost-Effectiveness

While the initial investment in graphite electrodes may be higher than alternative materials, their durability and efficiency lead to lower operating costs over time. The extended lifespan of these electrodes reduces the need for frequent replacements, ultimately saving businesses money.

Quality of Metal Production

The use of high-quality graphite electrodes contributes to superior-quality metal production. The controlled melting environment achieved with these electrodes minimizes imperfections in the final product, leading to improved mechanical properties and overall performance of the metal.

Applications of Graphite Electrodes in Metallurgy

Steel Production

Graphite electrodes are extensively used in steel production through electric arc furnaces. They facilitate the melting of scrap steel and other metallic materials, allowing for efficient recycling and production of high-quality steel grades.

Non-Ferrous Metal Production

In addition to steel, graphite electrodes are also employed in the production of non-ferrous metals such as aluminum, copper, and zinc. Their ability to withstand extreme conditions makes them suitable for various metallurgical processes involving different materials.

Specialty Alloys

Graphite electrodes play a vital role in producing specialty alloys, which require precise control over temperature and chemical composition during melting. The thermal stability and conductivity of these electrodes are essential for achieving desired properties in complex alloys.

The Future of Graphite Electrodes in Metallurgy

Innovations and Developments

The metallurgy industry is constantly evolving, with ongoing research focused on improving graphite electrode technology. Innovations in material science and electrode manufacturing techniques are expected to enhance performance, reduce costs, and optimize the melting process further.

Environmental Considerations

As sustainability becomes a key focus in metallurgy, the production and use of graphite electrodes are also adapting to meet environmental standards. Research into eco-friendly alternatives and recycling methods for graphite electrodes is underway to minimize waste and reduce the industry's carbon footprint.

Challenges Facing Graphite Electrodes

Supply Chain Issues

The global supply chain for graphite electrodes can be affected by geopolitical factors, leading to price volatility and availability concerns. Companies must navigate these challenges to ensure a steady supply of quality electrodes for their operations.

Competition from Alternative Materials

While graphite electrodes are preferred for many applications, competition from alternative materials, such as silicon carbide and other non-graphitic conductors, is emerging. Continuous advancements in technology may lead to new materials that challenge the dominance of traditional graphite electrodes.

Frequently Asked Questions (FAQs)

1. What is the main function of graphite electrodes in metallurgy?

Graphite electrodes mainly serve to conduct electrical currents in electric arc furnaces, facilitating the melting and processing of metals.

2. Why are graphite electrodes preferred over other materials?

Their unique properties, such as high electrical conductivity, thermal resistance, and chemical stability, make them ideal for demanding metallurgical applications.

3. How do graphite electrodes impact the quality of metal production?

Graphite electrodes contribute to a controlled melting process, which minimizes imperfections in the metal, thereby enhancing its mechanical properties and overall quality.

4. Are there any environmental concerns associated with graphite electrodes?

Yes, the production and disposal of graphite electrodes pose environmental challenges, leading to research focused on sustainable practices and alternative materials.

5. What are the future trends in graphite electrode technology?

Future trends include advancements in manufacturing processes, the development of eco-friendly alternatives, and innovations aimed at improving performance and reducing costs.

Conclusion

In conclusion, graphite electrodes stand out as a preferred choice in metallurgy due to their unmatched properties, efficiency, and cost-effectiveness. Their application in electric arc furnaces facilitates superior metal production, contributing significantly to the steel and non-ferrous metal industries. As the landscape of metallurgy continues to evolve, the role of graphite electrodes promises to remain pivotal, highlighting the need for ongoing innovation and adaptation to meet future demands.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property