Understanding Calcined Petroleum Coke: Properties, Uses, and Benefits

Summary:

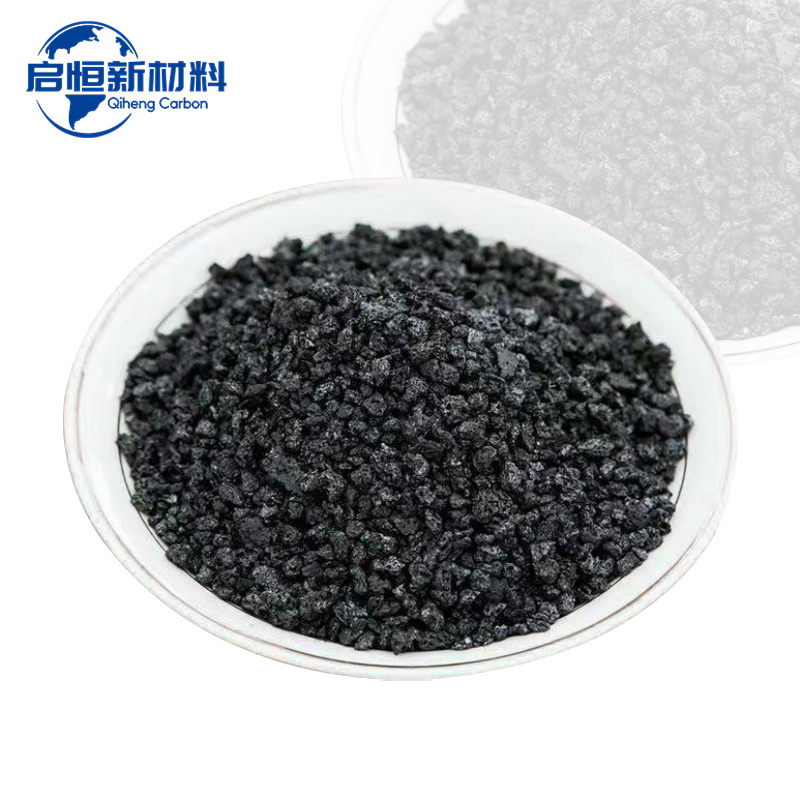

Calcined petroleum coke (CPC) is a carbonaceous material produced from the calcination of green petroleum coke, a byproduct of refining crude oil. The process involves heating the green coke to high temperatures in a controlled environment, driving off volatile substances and resulting in a dense, porous structure primarily composed of carbon. This transformation not only enhances its purity but a

Calcined petroleum coke (CPC) is a carbonaceous material produced from the calcination of green petroleum coke, a byproduct of refining crude oil. The process involves heating the green coke to high temperatures in a controlled environment, driving off volatile substances and resulting in a dense, porous structure primarily composed of carbon. This transformation not only enhances its purity but also improves its physical and chemical properties, making it suitable for various applications.

One of the key characteristics of calcined petroleum coke is its high carbon content, typically exceeding 99%. This property makes it an excellent choice for industries requiring high-quality carbon materials, particularly in the production of aluminum and other non-ferrous metals. In aluminum smelting, CPC serves as a critical anode material, facilitating the electrolysis process essential for aluminum production. The high conductivity and low impurities of calcined petroleum coke contribute to increased efficiency and reduced energy consumption in the smelting process.

Another important application of calcined petroleum coke is in the manufacturing of carbon electrodes used in electric arc furnaces for steel production. The durability and thermal resistance of CPC make it an ideal material for electrodes that must withstand extreme temperatures and corrosive environments. Moreover, its use in the production of graphite electrodes aids in enhancing the performance and life span of these crucial components in steelmaking.

Additionally, calcined petroleum coke is finding increasing use in the production of lithium-ion batteries, where it serves as a conductive additive. Its high electrical conductivity and low ash content contribute to improved battery performance and energy density, which are essential in the growing market for electric vehicles and renewable energy storage solutions.

The benefits of using calcined petroleum coke extend beyond its high carbon content and performance characteristics. The production of CPC generally involves less energy than other carbon materials, aligning with industry trends towards more sustainable practices. Furthermore, the recycling of petroleum coke helps reduce waste from the refining process, promoting environmental stewardship.

In summary, calcined petroleum coke is a versatile and valuable material with significant applications across multiple industries. Its unique properties, such as high carbon content, thermal resistance, and conductivity, make it indispensable in aluminum production, steel manufacturing, and battery technologies. As industries continue to seek efficient and sustainable solutions, the demand for calcined petroleum coke is likely to grow, highlighting its importance in the petrochemical sector.

One of the key characteristics of calcined petroleum coke is its high carbon content, typically exceeding 99%. This property makes it an excellent choice for industries requiring high-quality carbon materials, particularly in the production of aluminum and other non-ferrous metals. In aluminum smelting, CPC serves as a critical anode material, facilitating the electrolysis process essential for aluminum production. The high conductivity and low impurities of calcined petroleum coke contribute to increased efficiency and reduced energy consumption in the smelting process.

Another important application of calcined petroleum coke is in the manufacturing of carbon electrodes used in electric arc furnaces for steel production. The durability and thermal resistance of CPC make it an ideal material for electrodes that must withstand extreme temperatures and corrosive environments. Moreover, its use in the production of graphite electrodes aids in enhancing the performance and life span of these crucial components in steelmaking.

Additionally, calcined petroleum coke is finding increasing use in the production of lithium-ion batteries, where it serves as a conductive additive. Its high electrical conductivity and low ash content contribute to improved battery performance and energy density, which are essential in the growing market for electric vehicles and renewable energy storage solutions.

The benefits of using calcined petroleum coke extend beyond its high carbon content and performance characteristics. The production of CPC generally involves less energy than other carbon materials, aligning with industry trends towards more sustainable practices. Furthermore, the recycling of petroleum coke helps reduce waste from the refining process, promoting environmental stewardship.

In summary, calcined petroleum coke is a versatile and valuable material with significant applications across multiple industries. Its unique properties, such as high carbon content, thermal resistance, and conductivity, make it indispensable in aluminum production, steel manufacturing, and battery technologies. As industries continue to seek efficient and sustainable solutions, the demand for calcined petroleum coke is likely to grow, highlighting its importance in the petrochemical sector.

Previous:

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property