Common Misconceptions About Graphite Electrode Connectors: Debunked

Summary:

Common Misconceptions About Graphite Electrode Connectors: Debunked

Table of Contents

Introduction to Graphite Electrode Connectors

Misconception 1: Graphite Electrodes Are Only Used for High-Temperature Applications

Misconception 2: All Graphite Electrodes Have the Same Properties

Misconception 3: Graphite Electrode Connectors Are Difficult to Install

Misconception 4: Graphite Electrod

Common Misconceptions About Graphite Electrode Connectors: Debunked

Table of Contents

- Introduction to Graphite Electrode Connectors

- Misconception 1: Graphite Electrodes Are Only Used for High-Temperature Applications

- Misconception 2: All Graphite Electrodes Have the Same Properties

- Misconception 3: Graphite Electrode Connectors Are Difficult to Install

- Misconception 4: Graphite Electrode Connectors Are Not Durable

- Misconception 5: High Cost Equals Higher Quality

- Misconception 6: Graphite Electrode Connectors Are Not Environmentally Friendly

- Best Practices for Using Graphite Electrode Connectors

- Conclusion

- Frequently Asked Questions

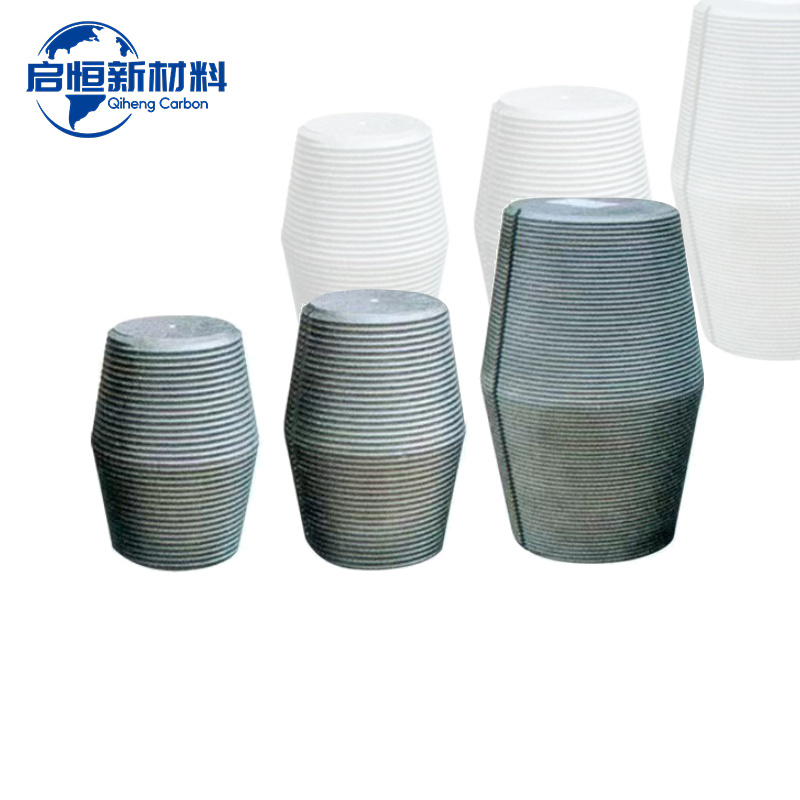

Introduction to Graphite Electrode Connectors

Graphite electrode connectors play a pivotal role in various industries, especially in electrical and industrial applications. These connectors provide a reliable and efficient means of electrical conduction, making them essential components in conducting electricity. However, several misconceptions about graphite electrode connectors can lead to misunderstandings regarding their functionality, value, and application. In this article, we aim to debunk these myths to provide a clearer picture of graphite electrode connectors.

Misconception 1: Graphite Electrodes Are Only Used for High-Temperature Applications

One of the most common misconceptions is that graphite electrodes are solely utilized in high-temperature environments, such as electric arc furnaces. While it is true that they excel in high-heat settings, **graphite electrodes** also serve in various other applications. These include:

- **Electrolysis**: Used in processes that require stable conductivity.

- **Welding**: Essential in certain welding techniques that demand high conductivity.

- **Battery Manufacturing**: Their ability to withstand heat makes them suitable for lithium-ion battery production.

Thus, limiting the understanding of graphite electrodes to high-temperature applications neglects their versatility in numerous other fields.

Misconception 2: All Graphite Electrodes Have the Same Properties

Another prevalent myth is the assumption that all graphite electrodes possess identical characteristics. In reality, graphite electrodes can vary significantly based on:

- **Composition**: Different grades of petroleum or needle coke are used, affecting performance.

- **Manufacturing Process**: The production methods can alter the microstructure and subsequent electrical properties.

- **Application Requirements**: Some applications may necessitate specific types of electrodes tailored for their unique needs.

Understanding these differences is crucial for selecting the right graphite electrode for a particular application, ensuring optimal performance and longevity.

Misconception 3: Graphite Electrode Connectors Are Difficult to Install

Many believe that the installation of graphite electrode connectors is a complex and challenging task. In truth, modern connectors are designed for user-friendliness, with many featuring:

- **Pre-assembled components**: Reducing installation time and complexity.

- **Clear instructions**: Providing step-by-step guidance for proper installation.

- **Compatibility with tools**: Easily fitting standard tools, making installation hassle-free.

With the right guidance and tools, installing graphite electrode connectors can be a straightforward process, easily managed by professionals and technicians alike.

Misconception 4: Graphite Electrode Connectors Are Not Durable

Durability is often a concern when it comes to graphite electrode connectors. However, this perception stems from a lack of understanding of their construction and materials. Quality graphite electrode connectors are made from robust materials that ensure longevity, including:

- **High-density graphite**: Providing superior wear resistance.

- **Resilient coatings**: Protecting against environmental factors such as moisture and corrosion.

When properly maintained, these connectors can last indefinitely, outpacing less durable alternatives in terms of reliability and performance.

Misconception 5: High Cost Equals Higher Quality

Many professionals operating in industries that utilize graphite electrode connectors assume that a higher price tag correlates with better quality. While cost can be an indicator of quality, it is not always a guarantee. Factors to consider include:

- **Brand reputation**: Established manufacturers may charge more due to their proven reliability.

- **Material standards**: Higher-quality materials can lead to increased performance, but there are affordable options that meet industry standards just as effectively.

- **Market demand**: Prices can fluctuate based on market conditions, affecting perceived quality.

Thus, it is essential to evaluate graphite electrode connectors based on specifications, performance, and brand reputation rather than solely on price.

Misconception 6: Graphite Electrode Connectors Are Not Environmentally Friendly

Some argue that graphite electrode connectors pose environmental issues due to their carbon content. However, **graphite** is a natural material, and when sourced responsibly, it can be environmentally benign. Additionally, advancements in technology have led to:

- **Recyclability**: Many graphite products, including connectors, can be recycled.

- **Sustainable sourcing**: Manufacturers are increasingly adopting practices that minimize environmental impact.

By choosing ethically produced graphite electrode connectors, companies can maintain their commitment to sustainability while benefiting from these essential tools.

Best Practices for Using Graphite Electrode Connectors

To maximize the performance and longevity of graphite electrode connectors, consider implementing the following best practices:

- **Regular inspections**: Regularly check connectors for wear and damage.

- **Proper storage**: Store connectors in a dry, clean environment to prevent contamination.

- **Follow manufacturer guidelines**: Adhere to recommended installation and maintenance protocols.

- **Training and education**: Ensure that all staff are trained in the best practices for handling and installing these connectors.

By adhering to these guidelines, users can ensure optimal performance and reliability from their graphite electrode connectors.

Conclusion

Graphite electrode connectors are invaluable tools across various industries, but misconceptions surrounding their use can lead to misunderstandings. Through debunking these myths, we have highlighted their versatility, durability, and importance in modern applications. As the industry continues to evolve, understanding the realities of graphite electrode connectors will empower professionals to make informed decisions, enhancing overall operational efficiency.

Frequently Asked Questions

1. What are the main benefits of using graphite electrode connectors?

Graphite electrode connectors offer high conductivity, durability, and resistance to high temperatures and environmental conditions, making them ideal for various applications.

2. How do I choose the right graphite electrode connector for my needs?

Consider factors such as application requirements, material specifications, and the manufacturer’s reputation when selecting a graphite electrode connector.

3. Are there any special maintenance requirements for graphite electrode connectors?

Regular inspections, proper storage, and adherence to manufacturer guidelines are crucial for maintaining the performance of graphite electrode connectors.

4. Can graphite electrode connectors be recycled?

Yes, many graphite products, including electrode connectors, can be recycled, contributing to sustainability efforts.

5. What common industries utilize graphite electrode connectors?

Industries such as metallurgy, battery manufacturing, and welding commonly use graphite electrode connectors due to their unique properties and performance advantages.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property