The Essential Guide to Graphite Blocks: Properties, Applications, and Benefits

Summary:

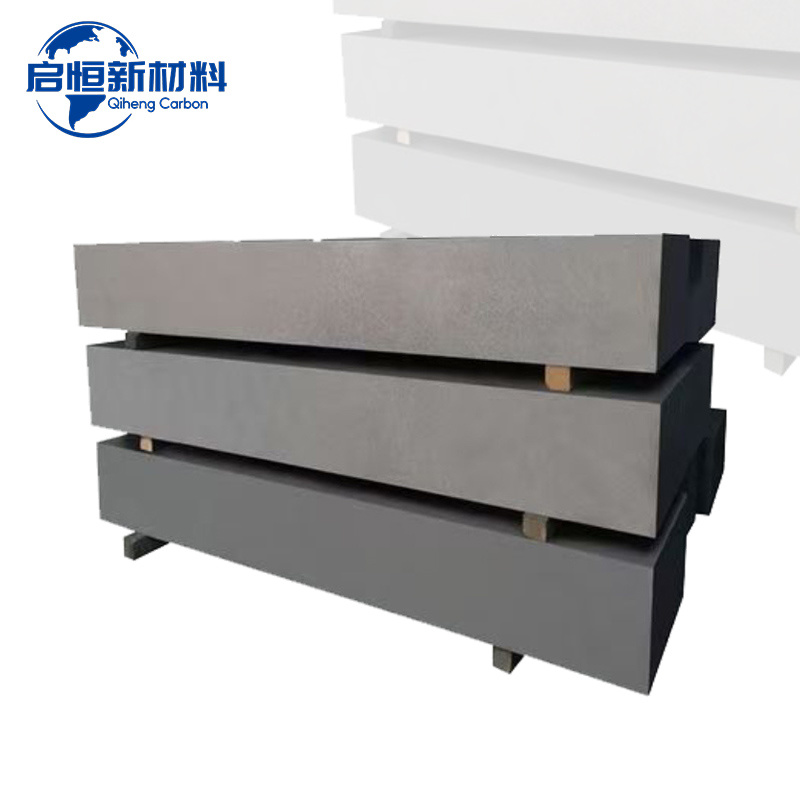

Graphite blocks are versatile materials derived from natural graphite or synthetic processes, characterized by their unique properties such as high thermal conductivity, chemical inertness, and excellent lubricating capabilities. These qualities make graphite blocks indispensable in various industries, especially in metallurgy and energy sectors where high temperatures and aggressive environments

Graphite blocks are versatile materials derived from natural graphite or synthetic processes, characterized by their unique properties such as high thermal conductivity, chemical inertness, and excellent lubricating capabilities. These qualities make graphite blocks indispensable in various industries, especially in metallurgy and energy sectors where high temperatures and aggressive environments are prevalent.

One of the most notable properties of graphite blocks is their exceptional thermal conductivity. This property allows them to efficiently transfer heat, making them ideal for applications in electric arc furnaces and crucibles. In metallurgy, graphite blocks are widely used as refractory linings due to their ability to withstand intense temperatures while maintaining structural integrity. This capability not only enhances the efficiency of metallurgical processes but also contributes to the safety and longevity of the equipment used.

Another significant feature of graphite blocks is their chemical resistance. Graphite is largely inert to most chemicals, which makes it suitable for use in corrosive environments. This characteristic is particularly beneficial in battery manufacturing and chemical processing, where materials are often exposed to harsh substances. Using graphite blocks in these applications helps prevent degradation and ensures the reliability and effectiveness of the final product.

In addition to their functional properties, graphite blocks also offer advantages in terms of sustainability. As industries shift towards greener practices, the use of graphite can help reduce carbon footprints. For instance, graphite is an essential component in the production of lithium-ion batteries, which power electric vehicles and renewable energy storage systems. By facilitating the transition to cleaner energy sources, graphite blocks play a pivotal role in promoting environmental sustainability.

Moreover, the versatility of graphite blocks extends to their applications in various industries beyond metallurgy and energy. For instance, they are utilized in the production of lubricants, brake linings, and even in the electronics sector, where they serve as conductive components in devices. This wide range of applications highlights the importance of graphite blocks as a fundamental material in modern technology and industry.

In conclusion, graphite blocks are invaluable materials in the fields of metallurgy and energy, thanks to their unique properties and broad applicability. Their high thermal conductivity, chemical resistance, and role in promoting sustainability make them essential in various industrial processes. As industries continue to evolve, understanding the significance of graphite blocks will be critical for professionals looking to leverage their benefits effectively.

One of the most notable properties of graphite blocks is their exceptional thermal conductivity. This property allows them to efficiently transfer heat, making them ideal for applications in electric arc furnaces and crucibles. In metallurgy, graphite blocks are widely used as refractory linings due to their ability to withstand intense temperatures while maintaining structural integrity. This capability not only enhances the efficiency of metallurgical processes but also contributes to the safety and longevity of the equipment used.

Another significant feature of graphite blocks is their chemical resistance. Graphite is largely inert to most chemicals, which makes it suitable for use in corrosive environments. This characteristic is particularly beneficial in battery manufacturing and chemical processing, where materials are often exposed to harsh substances. Using graphite blocks in these applications helps prevent degradation and ensures the reliability and effectiveness of the final product.

In addition to their functional properties, graphite blocks also offer advantages in terms of sustainability. As industries shift towards greener practices, the use of graphite can help reduce carbon footprints. For instance, graphite is an essential component in the production of lithium-ion batteries, which power electric vehicles and renewable energy storage systems. By facilitating the transition to cleaner energy sources, graphite blocks play a pivotal role in promoting environmental sustainability.

Moreover, the versatility of graphite blocks extends to their applications in various industries beyond metallurgy and energy. For instance, they are utilized in the production of lubricants, brake linings, and even in the electronics sector, where they serve as conductive components in devices. This wide range of applications highlights the importance of graphite blocks as a fundamental material in modern technology and industry.

In conclusion, graphite blocks are invaluable materials in the fields of metallurgy and energy, thanks to their unique properties and broad applicability. Their high thermal conductivity, chemical resistance, and role in promoting sustainability make them essential in various industrial processes. As industries continue to evolve, understanding the significance of graphite blocks will be critical for professionals looking to leverage their benefits effectively.

Previous:

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property