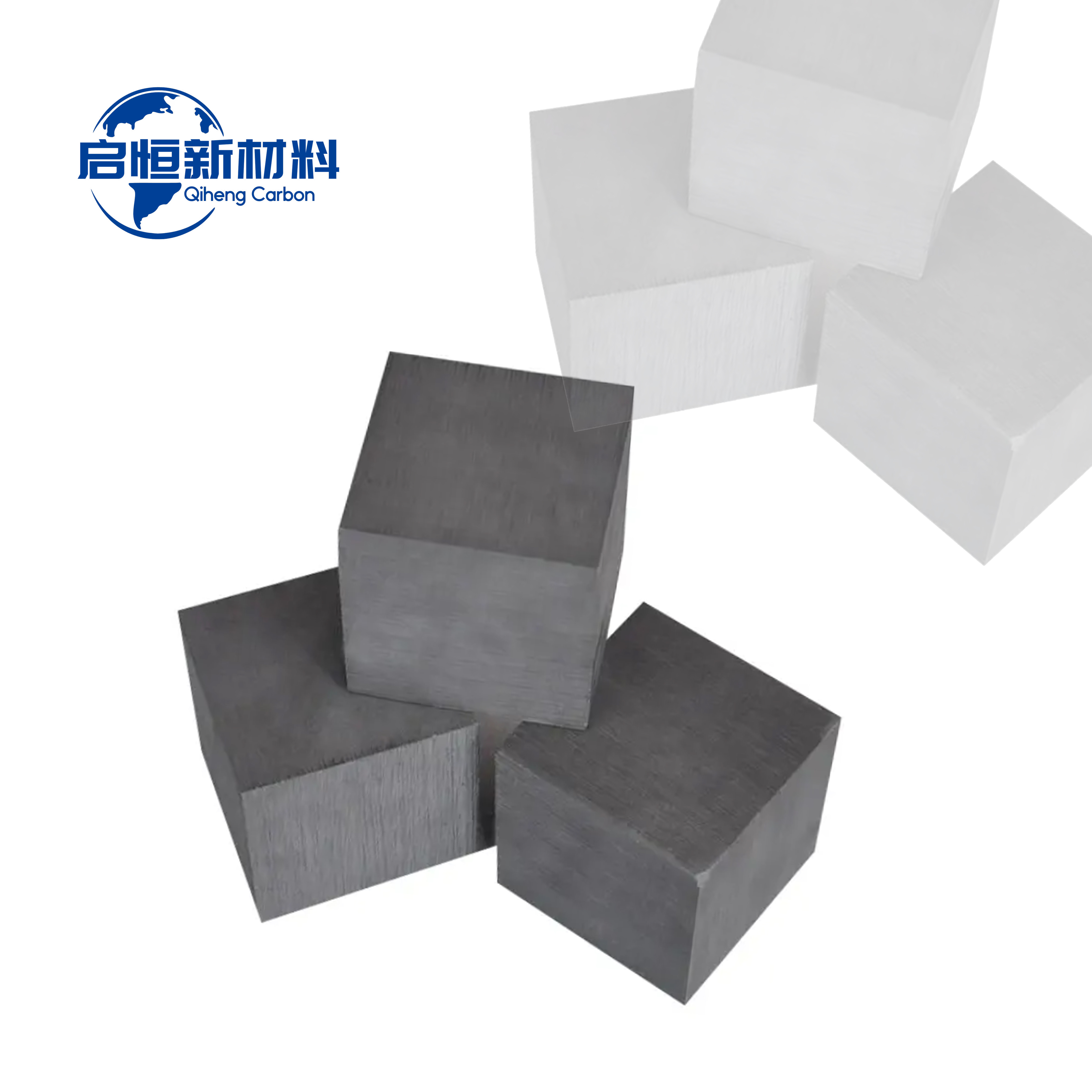

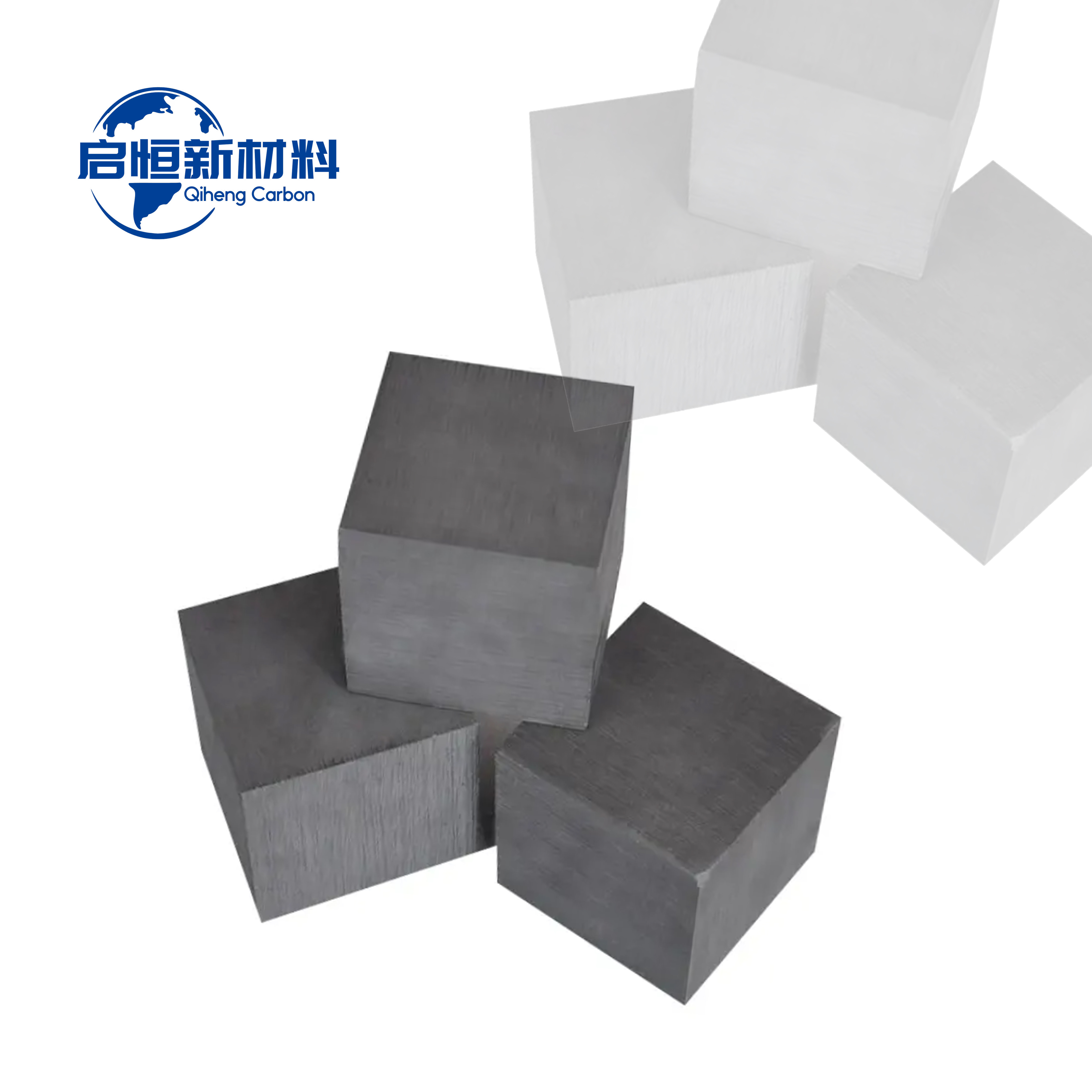

China's Customized Graphite Blocks Meet Diverse Industrial Requirements

The industrial materials sector is observing growing demand for specialized components with the introduction of customized graphite blocks from China manufacturers, offering tailored solutions for high-temperature and chemically aggressive applications. These precision-engineered materials demonstrate adaptability across multiple technical fields.

Customized graphite blocks from China manufacturers provide measurable advantages for metallurgical, semiconductor, and energy applications. The ability to produce blocks with specific density, porosity, and dimensional characteristics allows optimal performance in different operational environments. Many formulations now feature enhanced thermal conductivity while maintaining structural stability at extreme temperatures exceeding 3000°C.

For process engineers and equipment designers, customized graphite blocks from China manufacturers offer reliable solutions for challenging conditions. The material's inherent corrosion resistance combines with customizable purity levels to meet strict requirements in chemical processing and crystal growth applications. The machinability permits creation of complex geometries for specialized furnace components and thermal management systems.

The technical properties of customized graphite blocks from China manufacturers include adjustable electrical resistivity and thermal expansion coefficients. These characteristics enable precise matching to specific process requirements in lithium-ion battery production and solar cell manufacturing. The availability of ultra-high purity grades (99.99% carbon) addresses needs in semiconductor and nuclear applications.

The manufacturing expertise behind customized graphite blocks from China manufacturers focuses on practical application requirements. By offering tailored solutions across density ranges (1.6-1.9 g/cm³) and multiple size configurations, these products demonstrate China's growing capability in advanced material engineering for demanding industrial applications.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries