Top Trends in UHP Graphite Electrode Technology You Should Know

Summary:

Top Trends in UHP Graphite Electrode Technology You Should Know

Table of Contents

Introduction to UHP Graphite Electrodes

Importance of UHP Graphite Electrodes in Metallurgy

Recent Trends in UHP Graphite Electrode Technology

Innovative Materials and Production Techniques

Performance Enhancements and Applications

Sustainability in UHP Graphi

Top Trends in UHP Graphite Electrode Technology You Should Know

Table of Contents

- Introduction to UHP Graphite Electrodes

- Importance of UHP Graphite Electrodes in Metallurgy

- Recent Trends in UHP Graphite Electrode Technology

- Innovative Materials and Production Techniques

- Performance Enhancements and Applications

- Sustainability in UHP Graphite Electrode Production

- Emerging Technologies in Electrode Manufacturing

- Market Insights and Future Outlook

- Challenges in UHP Graphite Electrode Technology

- FAQs

- Conclusion

Introduction to UHP Graphite Electrodes

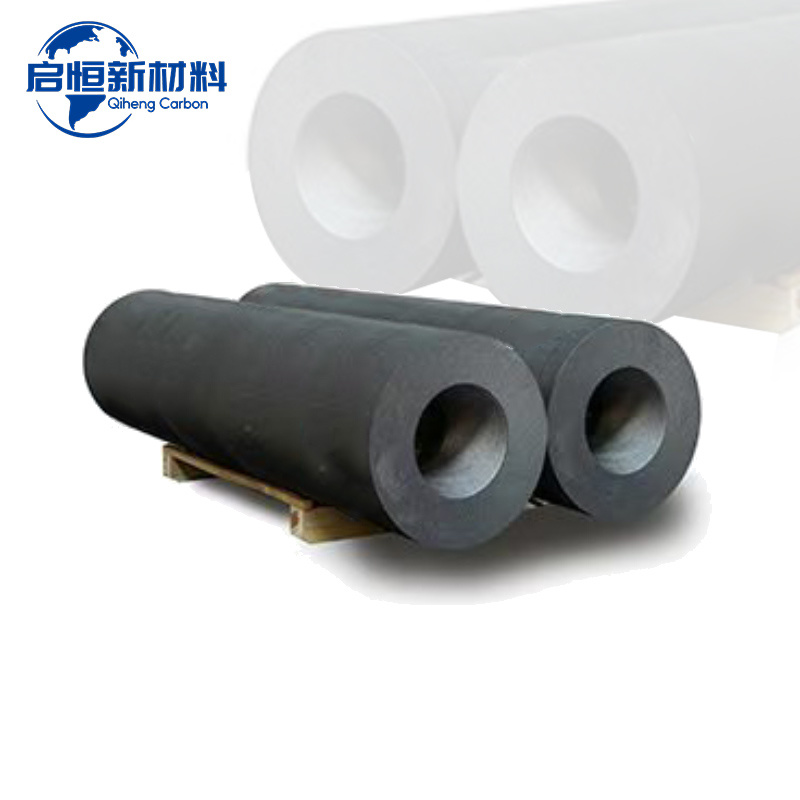

The global metallurgical industry is experiencing a significant transformation, primarily driven by advancements in UHP graphite electrode technology. UHP graphite electrodes are critical components in the electric arc furnace (EAF) steelmaking process, facilitating efficient energy transfer and high-temperature operations. As industries evolve, so do the materials and technologies that underpin them. Understanding these changes is essential for stakeholders aiming to optimize their processes and remain competitive.

Importance of UHP Graphite Electrodes in Metallurgy

UHP graphite electrodes play an instrumental role in the production of steel and other metals, enabling high-efficiency smelting. The unique properties of graphite, including its high thermal conductivity, low thermal expansion, and chemical resistance, make it ideal for high-temperature applications. As the demand for high-quality steel increases, so does the need for advanced UHP graphite electrode technology that can support modern manufacturing requirements.

Recent Trends in UHP Graphite Electrode Technology

The UHP graphite electrode market has seen several significant trends in recent years. Here, we explore the most notable advancements shaping the sector.

Innovative Materials and Production Techniques

One of the most impactful trends in UHP graphite electrode technology is the exploration of innovative materials and production techniques. Manufacturers are increasingly adopting new carbon-based materials that enhance the performance and lifespan of electrodes. These innovations include:

- **High-Purity Graphite**: Enhanced purity levels in raw materials significantly improve electrode performance.

- **Nano-Graphite Additives**: Incorporating nano-sized graphite particles can enhance conductivity and thermal stability.

- **Advanced Sintering Techniques**: Techniques such as hot isostatic pressing (HIP) are being utilized to improve the density and structure of electrodes, resulting in better mechanical properties.

Performance Enhancements and Applications

Ongoing research and development in UHP graphite electrodes have led to remarkable performance enhancements. These advancements include:

- **Increased Density and Strength**: New compaction methods are yielding electrodes with superior strength, which can withstand the rigors of modern EAF operations.

- **Improved Thermal Conductivity**: Enhanced thermal properties enable more efficient energy transfer, reducing operational costs and increasing productivity.

- **Optimized Electrode Design**: Innovations in electrode design, such as tailored geometries, contribute to improved melting performance and reduced wear.

These performance enhancements allow manufacturers to achieve higher yields and lower operational costs while ensuring compliance with environmental regulations.

Sustainability in UHP Graphite Electrode Production

Sustainability has become a pressing concern across various industries, including metallurgy. UHP graphite electrode manufacturers are increasingly focusing on sustainable production practices, including:

- **Recycling and Reuse**: Efforts to recycle spent electrodes not only reduce waste but also lower the demand for raw materials.

- **Eco-Friendly Manufacturing Processes**: Implementing cleaner production technologies minimizes environmental impact, aligning with global sustainability goals.

- **Carbon Neutral Initiatives**: Many companies are exploring carbon capture and storage (CCS) technologies to offset emissions associated with electrode production.

These initiatives not only help companies meet regulatory requirements but also cater to an increasingly environmentally conscious market.

Emerging Technologies in Electrode Manufacturing

As the UHP graphite electrode market evolves, several emerging technologies are set to redefine manufacturing processes. Key developments include:

- **3D Printing**: This technology allows for the precise fabrication of complex electrode geometries, optimizing performance and reducing waste.

- **AI and Machine Learning**: Implementing AI-driven analytics can enhance quality control and optimize production processes by predicting potential failures and improving yield rates.

- **Automation and Robotics**: The integration of automated systems in manufacturing lines can enhance efficiency, reduce labor costs, and improve safety.

These technologies represent a significant leap forward in electrode manufacturing, ensuring that producers can meet the growing demands of the market.

Market Insights and Future Outlook

The UHP graphite electrode market is poised for substantial growth in the coming years. Several factors are driving this development, including:

- **Increased Demand for Steel**: The global push for infrastructure development and urbanization is driving steel demand, thus increasing the need for UHP graphite electrodes.

- **Technological Advancements**: Continuous innovations in electrode materials and manufacturing processes are expected to boost production efficiency and product quality.

- **Expansion of Electric Arc Furnaces**: The rising adoption of EAFs over traditional blast furnaces is a clear trend, further fueling the demand for UHP graphite electrodes.

Industry analysts anticipate that the UHP graphite electrode market will continue to grow, driven by these factors and the ongoing transition toward more sustainable and efficient production methods.

Challenges in UHP Graphite Electrode Technology

Despite the promising trends, several challenges persist in the UHP graphite electrode market:

- **Raw Material Sourcing**: The availability of high-quality raw materials is a concern, particularly as the demand for graphite increases.

- **Cost Pressures**: Fluctuations in raw material prices can impact overall manufacturing costs, necessitating efficient resource management.

- **Regulatory Compliance**: Navigating the complex landscape of environmental regulations can pose challenges for manufacturers seeking to remain compliant while pursuing sustainability initiatives.

Addressing these challenges will be crucial for manufacturers to ensure long-term success in the UHP graphite electrode market.

FAQs

1. What are UHP graphite electrodes used for?

UHP graphite electrodes are primarily used in electric arc furnaces for steelmaking, facilitating the efficient transfer of electrical energy required to melt scrap steel and produce new steel products.

2. How do UHP graphite electrodes differ from regular graphite electrodes?

UHP graphite electrodes have higher density and conductivity compared to regular graphite electrodes, allowing them to handle higher power levels and temperatures, making them ideal for modern steelmaking.

3. What advancements are being made in UHP graphite electrode technology?

Advancements include the use of high-purity raw materials, innovative production techniques, and the implementation of emerging technologies such as 3D printing and AI analytics.

4. How do sustainability initiatives impact UHP graphite electrode production?

Sustainability initiatives aim to reduce environmental impact through recycling, cleaner production methods, and carbon neutral goals, thus appealing to an environmentally conscious market.

5. What is the future outlook for the UHP graphite electrode market?

The market is expected to grow significantly due to increasing steel demand, technological advancements, and the expansion of electric arc furnaces, alongside challenges related to raw material sourcing and regulatory compliance.

Conclusion

The UHP graphite electrode market is at the forefront of innovation, driven by technological advancements and the quest for sustainability. Understanding these trends is essential for industry stakeholders aiming to enhance their operations and remain competitive. As the demand for high-quality steel continues to rise, the role of UHP graphite electrodes will only become more critical in metallurgical processes. Embracing these trends will enable manufacturers to optimize performance, improve efficiency, and contribute positively to the evolving landscape of the industry.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property