Understanding the Production Process of Petroleum Coke: A Comprehensive Guide

Understanding the Production Process of Petroleum Coke

Table of Contents

- What is Petroleum Coke?

- Historical Background of Petroleum Coke Production

- Production Process of Petroleum Coke

- Feedstock Selection and Preparation

- Coking Process Explained

- Quenching and Cooling of Petroleum Coke

- Types of Petroleum Coke

- Applications of Petroleum Coke

- Environmental Impact of Petroleum Coke Production

- The Future of Petroleum Coke in Industry

- Conclusion

- Frequently Asked Questions

What is Petroleum Coke?

Petroleum coke, often referred to as petcoke, is a carbon-rich solid material derived from the oil refining process. It is produced when petroleum residues undergo thermal cracking, resulting in a byproduct that can be utilized in various industrial applications. With a high carbon content, petroleum coke serves as an essential ingredient in the manufacturing of aluminum, steel, and other products that require high-quality carbon sources.

Historical Background of Petroleum Coke Production

The production of petroleum coke dates back to the early 20th century, coinciding with advancements in petroleum refining technologies. As refiners sought to maximize the yield of valuable products from crude oil, the coking process emerged as a vital method for converting heavy hydrocarbons into lighter, more valuable fractions. Over the decades, the demand for petroleum coke has expanded, particularly in the aluminum and power generation industries, propelling innovations in production techniques.

Production Process of Petroleum Coke

The production of petroleum coke involves several critical steps, each playing a role in determining the quality and characteristics of the final product. Understanding these steps provides insights into how petcoke is created and its applications.

Feedstock Selection and Preparation

The journey of producing petroleum coke begins with selecting the appropriate feedstock, which typically consists of heavy oils and residual fractions from crude oil. This feedstock is subjected to preliminary treatment to ensure that impurities like sulfur and metals are minimized. Proper feedstock preparation is crucial as it directly influences the quality of the petroleum coke produced, affecting its carbon content and physical properties.

Coking Process Explained

At the heart of petroleum coke production lies the coking process, which can be divided into two main types: delayed coking and fluid coking. In delayed coking, the feedstock is heated in a coker unit, allowing it to undergo thermal cracking at high temperatures (typically between 900°F to 1,100°F). This process transforms the heavy hydrocarbons into lighter products while simultaneously forming solid petroleum coke.

Fluid coking, on the other hand, involves the continuous processing of feedstock in a fluidized bed reactor. This method allows for better heat transfer and more efficient cracking, yielding a higher quantity of petroleum coke. The choice between these methods depends on the specific requirements and objectives of the refining operation.

Quenching and Cooling of Petroleum Coke

Once the coking process is complete, the petroleum coke must be quenched to halt further thermal reactions. Quenching typically involves the use of water or steam, which cools the coke rapidly and enhances its structural integrity. After quenching, the petroleum coke is air-cooled to ambient temperatures before being processed further for various applications.

Types of Petroleum Coke

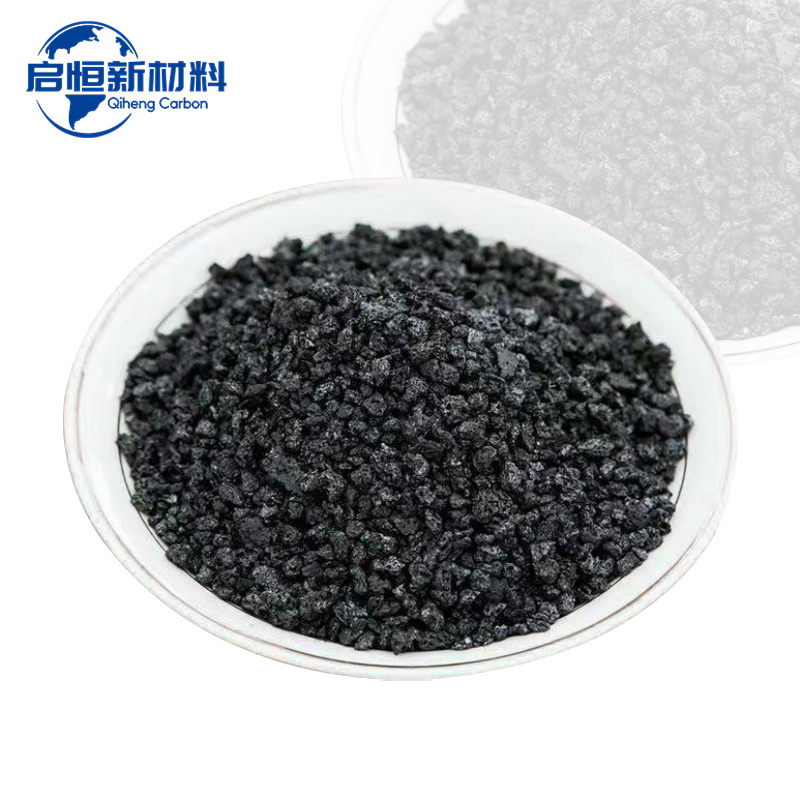

Petroleum coke can be categorized into different types based on its physical and chemical properties, primarily green petroleum coke and calcined petroleum coke.

Green Petroleum Coke

Green petroleum coke is the initial product obtained from the coking process. It contains a high volatile matter content and is primarily composed of carbon, sulfur, and trace elements. Green petcoke is typically utilized in applications that do not require high purity, such as fuel in power generation and as a carbon source in the manufacturing of electrodes.

Calcined Petroleum Coke

Calcined petroleum coke is produced by subjecting green petcoke to high-temperature treatment in a calcining furnace. This process removes volatile impurities and increases the carbon content, resulting in a material with enhanced properties suitable for high-performance applications like aluminum smelting and the production of graphite electrodes. The calcination process also improves the electrical conductivity of the coke, making it an essential component in the production of anodes for the aluminum industry.

Applications of Petroleum Coke

The versatility of petroleum coke allows it to find applications across various industries. Its primary uses include:

- Aluminum Production: Calcined petroleum coke is a crucial ingredient in the production of aluminum anodes, which are essential for the electrolytic reduction process in aluminum smelting.

- Electrode Manufacturing: The high carbon content of petroleum coke makes it suitable for producing graphite electrodes used in electric arc furnaces for steel manufacturing.

- Fuel Source: Green petroleum coke can be used as a solid fuel in power generation, offering an economical alternative to traditional fossil fuels.

- Cement Industry: Due to its high carbon content, petroleum coke is often used as a fuel substitute in cement kilns, contributing to energy efficiency in the manufacturing process.

Environmental Impact of Petroleum Coke Production

The production and use of petroleum coke raise environmental concerns, primarily related to air quality and greenhouse gas emissions. During the coking process, volatile organic compounds (VOCs) and sulfur oxides (SOx) can be released, contributing to air pollution. Additionally, the combustion of petroleum coke as fuel can emit carbon dioxide (CO2) and other harmful pollutants. As regulations tighten, the industry is exploring cleaner production methods and emissions reduction technologies to mitigate the environmental impact.

The Future of Petroleum Coke in Industry

As industries evolve and the demand for sustainable practices grows, the future of petroleum coke faces both challenges and opportunities. With advancements in technology, there is potential to enhance the efficiency of petcoke production while reducing its environmental footprint. Moreover, the increasing focus on recycling and innovative uses for petroleum coke, such as in the production of synthetic fuels and chemicals, may pave the way for its continued relevance in the modern industrial landscape.

Conclusion

Understanding the production process of petroleum coke is essential for recognizing its significance in various industries. From its origins in crude oil refining to its diverse applications in aluminum production and energy generation, petroleum coke continues to play a vital role in the global economy. As the industry faces environmental challenges, the push for cleaner production methods and innovative applications will shape the future landscape of this important material.

Frequently Asked Questions

1. What is the primary use of petroleum coke?

Petroleum coke is primarily used in the production of aluminum anodes, graphite electrodes, and as a fuel source in power generation.

2. How does the coking process work?

The coking process involves heating heavy petroleum residues at high temperatures to break down hydrocarbons into lighter products while forming solid petroleum coke.

3. What is the difference between green and calcined petroleum coke?

Green petroleum coke is the raw product from the coking process, while calcined petroleum coke is produced by heating green petcoke to remove impurities, enhancing its carbon content and properties.

4. What environmental concerns are associated with petroleum coke?

Environmental concerns include air pollution from emissions during production and combustion, as well as the greenhouse gas emissions associated with its use as a fuel.

5. What is the future outlook for petroleum coke?

The future of petroleum coke may involve cleaner production methods, innovative applications, and a growing emphasis on sustainability in its use.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries