How Petroleum Coke is Revolutionizing the Chemical Industry

Summary:

How Petroleum Coke is Revolutionizing the Chemical Industry

Table of Contents

1. Introduction to Petroleum Coke

2. What is Petroleum Coke?

3. The Production Process of Petroleum Coke

4. Key Applications of Petroleum Coke in the Chemical Industry

5. Environmental Impact of Petroleum Coke

6. Advantages of Using Petroleum Coke

7. The Future of Petroleum Coke in the Chemical Industry

How Petroleum Coke is Revolutionizing the Chemical Industry

Table of Contents

- 1. Introduction to Petroleum Coke

- 2. What is Petroleum Coke?

- 3. The Production Process of Petroleum Coke

- 4. Key Applications of Petroleum Coke in the Chemical Industry

- 5. Environmental Impact of Petroleum Coke

- 6. Advantages of Using Petroleum Coke

- 7. The Future of Petroleum Coke in the Chemical Industry

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Petroleum Coke

In the evolving landscape of the chemical industry, **petroleum coke** has emerged as a vital component that is reshaping traditional practices. This carbon-rich material, derived from crude oil, is intricately linked to various chemical applications, making it indispensable for modern manufacturing processes. By exploring its origins, applications, and environmental implications, we can understand how petroleum coke is revolutionizing the industry.

2. What is Petroleum Coke?

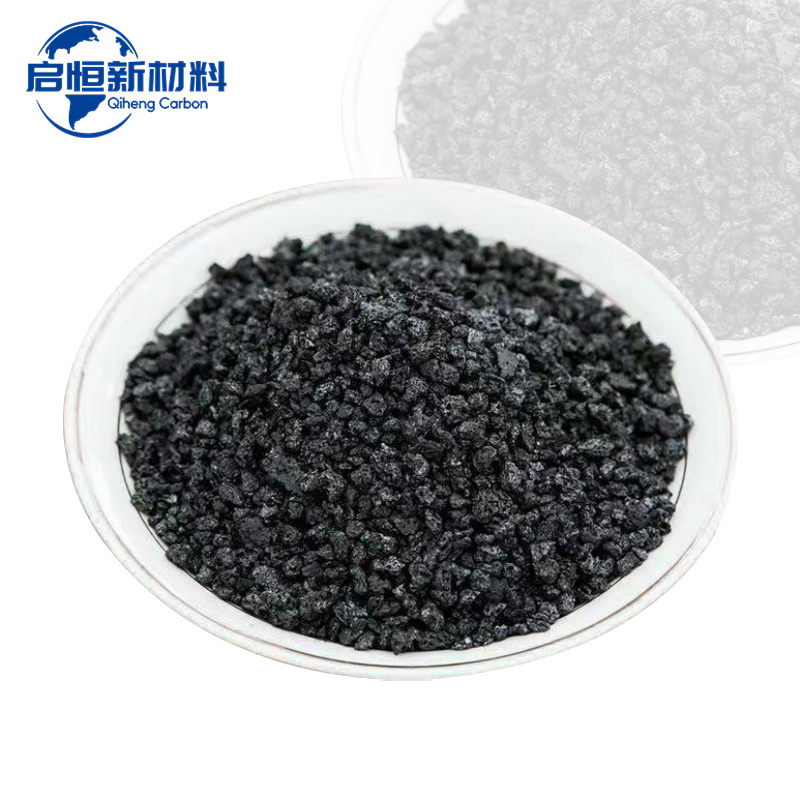

Petroleum coke, commonly referred to as petcoke, is a solid carbon material produced during the oil refining process. It is created through the thermal decomposition of crude oil, which separates lighter hydrocarbons from heavier fractions. Petcoke is primarily composed of carbon, with varying amounts of sulfur, hydrogen, nitrogen, and metals. This composition gives it unique properties that are beneficial for numerous industrial applications.

Types of Petroleum Coke

Petroleum coke is categorized into two main types: **green petroleum coke** and **calcined petroleum coke**.

- **Green Petroleum Coke:** This is the unprocessed form of petroleum coke, which is typically used in the production of electrodes and as a fuel source.

- **Calcined Petroleum Coke:** By heating green petcoke to high temperatures, calcined petroleum coke is produced, boasting higher carbon purity and lower impurities. This type is predominantly used in aluminum production and battery manufacturing.

3. The Production Process of Petroleum Coke

The production of petroleum coke begins in the **coking unit** of a refinery, where heavy crude oil is subjected to high temperatures (usually between 450°C to 500°C) in a vacuum. This thermal cracking process breaks down large hydrocarbons into simpler molecules, resulting in gaseous and liquid products, including petcoke.

Following the coking process, the petcoke is cooled and sent for further processing. For calcined petroleum coke, the green petcoke undergoes calcination in rotary kilns at temperatures exceeding 1200°C, removing volatile compounds and enhancing its carbon content.

This meticulous production process ensures that petroleum coke meets strict specifications for various applications, reinforcing its value in the chemical industry.

4. Key Applications of Petroleum Coke in the Chemical Industry

The versatility of petroleum coke is evident in its diverse applications across the chemical industry. Here are some of the most significant uses:

4.1. Aluminum Production

One of the most critical applications of calcined petroleum coke is in the **aluminum industry**. It serves as a key component in the production of anodes utilized in aluminum smelting. The high carbon content of calcined petcoke ensures optimal performance, making it essential for efficient aluminum production.

4.2. Electrode Manufacturing

Both green and calcined petroleum coke are crucial in manufacturing **graphite electrodes**. These electrodes are necessary for electric arc furnaces, used in steelmaking and other metallurgical processes. The conductivity and thermal resistance of petroleum coke make it an ideal choice, enhancing the performance of these electrodes.

4.3. Fuel Source

Green petroleum coke is an economical fuel source for various industrial processes. Its high carbon content and calorific value allow it to be utilized in power generation and cement manufacturing, providing a cost-effective alternative to traditional fossil fuels.

4.4. Carbon Black Production

Petroleum coke is also a prominent feedstock in the production of **carbon black**, a material widely used in the rubber and plastics industries. The carbon black produced from petcoke exhibits excellent reinforcing properties, enhancing the durability and performance of rubber products, particularly tires.

4.5. Chemical Feedstock

Beyond its direct applications, petroleum coke serves as a feedstock for the synthesis of various chemicals. It can be processed to produce **syngas**, which is subsequently converted into valuable chemicals such as methanol and hydrogen, contributing to the development of greener chemical processes.

5. Environmental Impact of Petroleum Coke

While petroleum coke offers numerous benefits, it is essential to consider its environmental implications. The combustion of petcoke can release significant amounts of **carbon dioxide (CO2)** and other pollutants, contributing to air quality issues and climate change.

However, advancements in technology and regulations have led to more efficient combustion processes and emissions control systems, minimizing the environmental footprint of petcoke usage. Additionally, the industry's shift toward **sustainable practices** can further mitigate these impacts, emphasizing the importance of responsible sourcing and utilization.

6. Advantages of Using Petroleum Coke

The growing reliance on petroleum coke in the chemical industry is attributed to several advantages:

6.1. Cost-Effectiveness

Petroleum coke is often more cost-effective than other carbon sources, allowing industries to reduce production costs while maintaining quality.

6.2. High Carbon Content

Its high carbon content makes petroleum coke an ideal substitute for other carbon materials, enhancing the performance of various products, particularly in aluminum and electrode manufacturing.

6.3. Availability

With the rise of oil production, the availability of petroleum coke has increased, ensuring a steady supply for industries reliant on this resource.

6.4. Versatility

The diverse applications of petroleum coke make it a versatile material that can serve multiple sectors, from energy production to chemical synthesis.

7. The Future of Petroleum Coke in the Chemical Industry

The future of petroleum coke in the chemical industry looks promising, driven by continuous innovations and advancements in technology. As industries prioritize sustainability, the demand for petroleum coke is expected to evolve, promoting research into cleaner combustion technologies and alternative uses.

Moreover, the integration of **circular economy principles** may lead to the development of new applications for petroleum coke, ensuring that it remains a valuable resource within the evolving chemical landscape.

As companies adapt to changing regulations and consumer preferences, the industry’s reliance on petroleum coke may shift towards more environmentally friendly practices, ultimately enhancing its role in the global economy.

8. Frequently Asked Questions

8.1. What is the primary use of petroleum coke?

The primary use of petroleum coke is in the aluminum production industry, where it is utilized in anodes for the smelting process. Additionally, it is used in electrode manufacturing and as a fuel source.

8.2. What are the environmental concerns related to petroleum coke?

The combustion of petroleum coke can result in the release of greenhouse gases and pollutants, contributing to air quality issues. However, advancements in technology aim to mitigate these environmental impacts.

8.3. How is petroleum coke produced?

Petroleum coke is produced during the refining of crude oil, specifically through a process called coking, where heavy hydrocarbons are thermally decomposed to yield solid carbon material.

8.4. Can petroleum coke be recycled?

Research into the recycling of petroleum coke is ongoing, with potential applications in sustainable practices. It can be transformed into syngas or utilized as a feedstock for other chemical processes.

8.5. What is calcined petroleum coke used for?

Calcined petroleum coke is primarily used in aluminum production, graphite electrode manufacturing, and as a precursor for carbon black production, due to its high carbon purity and reduced impurities.

9. Conclusion

In conclusion, **petroleum coke** is not just a byproduct of the oil refining process; it is a revolutionary material that is transforming the chemical industry. Its unique properties and versatility make it indispensable across various applications, from aluminum production to carbon black synthesis. As industries increasingly focus on sustainability and efficiency, the future of petroleum coke is poised for further innovation and development. By understanding its benefits and implications, stakeholders can leverage petroleum coke to drive progress in the chemical sector, ensuring its continued relevance in a rapidly changing world.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property